Best practice assembly and logistics

Modern assembly systems are capable of manufacturing complex and multi-variant products at competitive costs. They are capable of individual production and small series and are flexible with regard to fluctuations in the number of pieces. This also applies in a differentiated form to series production.

ROI-EFESO management consultancy has the necessary tools at its disposal:

With ROM®, the ROI operation sequence method, a waste-free assembly system is simulated in a short time on the basis of the parts list. Optimal assembly time and potential are thus determined.

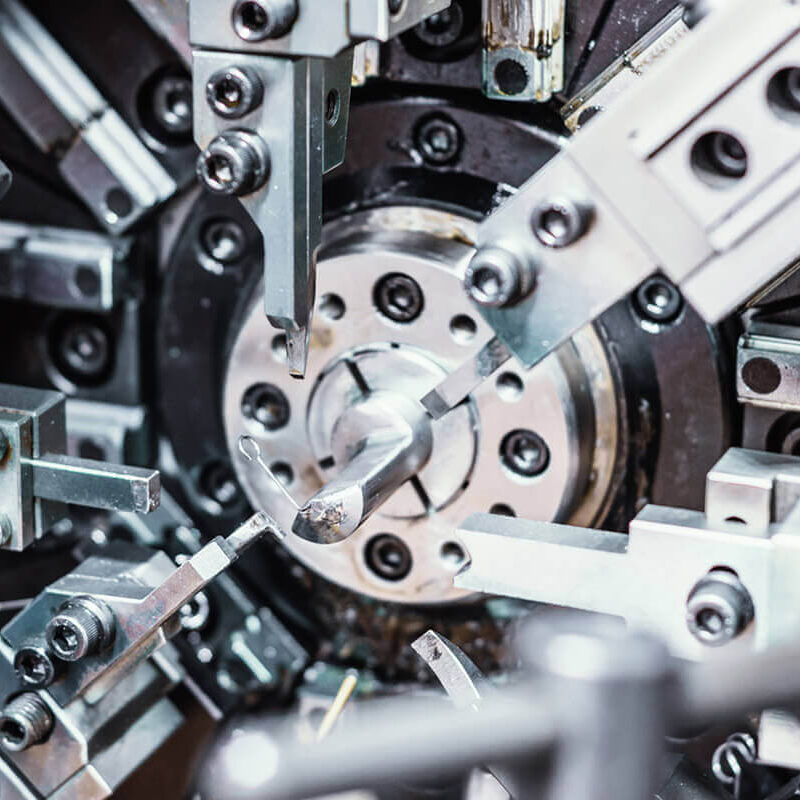

©Boleslawiec

The assembly system itself is developed from a best-practice modular system based on the following basic principles:

- clear separation of assembly and logistics,

- Introduction One-Piece-Flow,

- flexible timing,

- Optimal separation and integration of pre- and final assembly,

- reasonable automation, low cost intelligent automation,

- Use of industry 4.0 technologies,

- Pull principle and flexible retooling in parts supply,

- standardized replenishment processes,

- modular and use-neutral assembly system and workplace design,

- team-oriented and capacity flexible organizational concepts

- Ergonomically designed workplaces

- Electric forklift vs. diesel forklift (CO2 issue)

- Digitalisation as the basis for efficient and thus resource-saving processes

- Occupational safety (accidents, hazardous substances, ...)

In addition, ROM® can provide valuable input on aspects relevant to production and assembly which should already be taken into account in the product design phase.

![[Translate to English:] Warehouse 4.0, Intralogistik 4.0, Logistik](/fileadmin/user_upload/intralogistik-2030-roi-beratung.jpg)