Newsletter #12/2022 – Winner of the INDUSTRIE 4.0 AWARD 2022

In the December issue of our newsletter, we present the winners of the INDUSTRIE 4.0 AWARD 2022.

With groundbreaking solutions in the categories "SMART FACTORY", "SMART & SUSTAINABLE", "SMART AUTOMATION" and "SMART WORKFORCE", the winners of this year's competition convinced the independent jury and secured the title of the best Industry 4.0 project of the year.

We hope you enjoy discovering the excellent solutions.

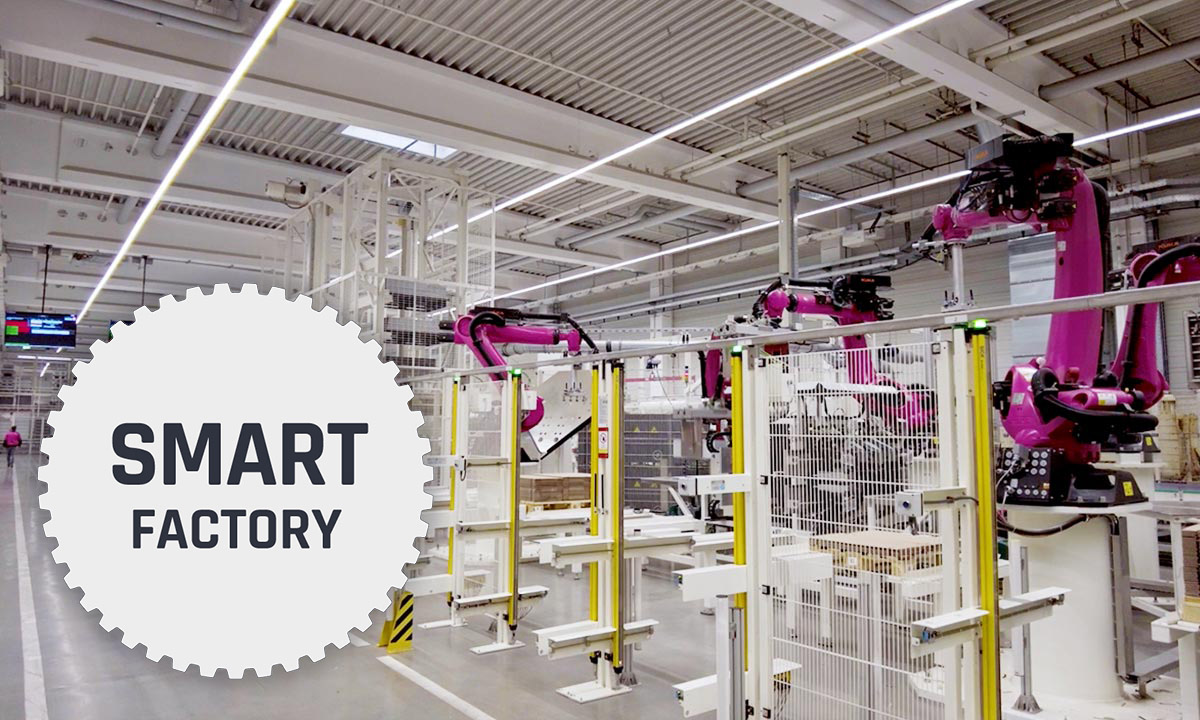

Winner in the "Smart Factory" category: Rittal GmbH

Rittal GmbH impressed the jury of the INDUSTRIE 4.0 AWARD 2022 with its end-to-end digitized and highly automated process chain from order entry, through production, to delivery to the customer. The manufacturer of enclosure systems, cooling devices and edge data center products has networked around 300 employees and 250 machines across all production lines at its site in Haiger. The data thus obtained flows into digital twins for the products, plants and production, thereby increasing transparency along the entire process chain.

More about the winning project

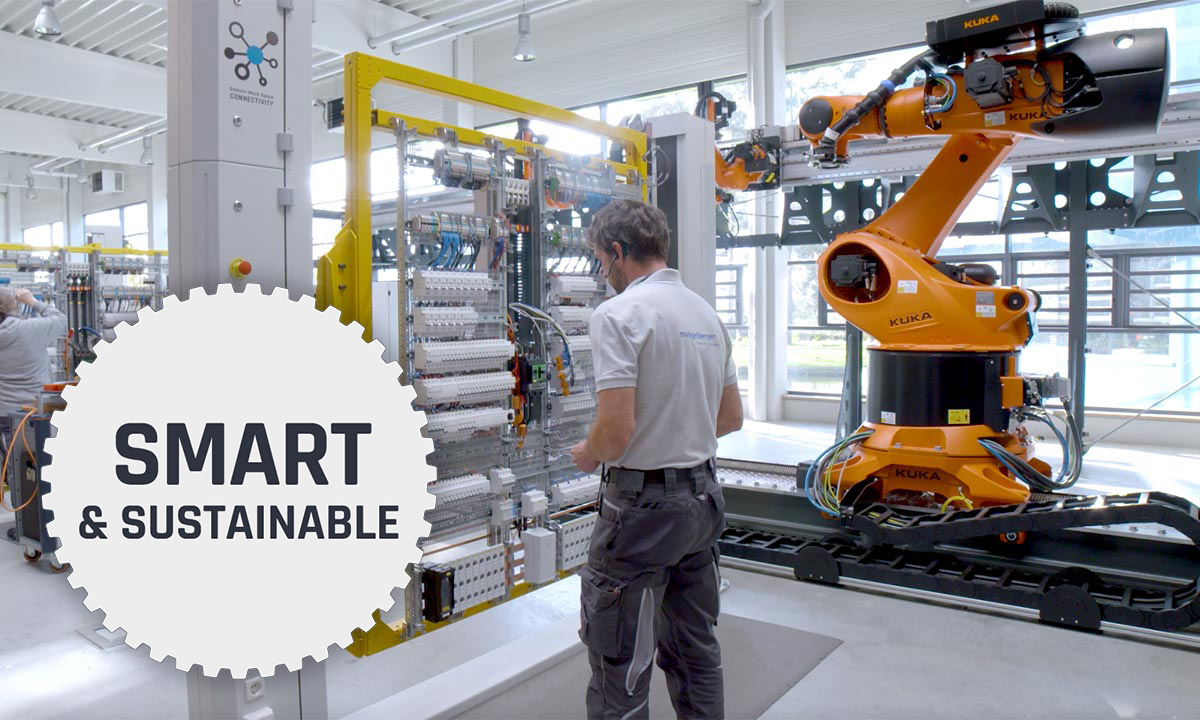

Winner in the category "SMART & SUSTAINABLE": Mangelberger Elektrotechnik GmbH

Reducing material costs and strengthening the circular economy in the plant is the focus of the award-winning Industry 4.0 solution from Mangelberger Elektrotechnik GmbH. To achieve this, the manufacturer of switchgear relies on the use of artificial intelligence and digital twins at its plant in Roth. AI software analyzes the performance of more than 8,000 enclosures in practical use and uses this data to select the right components for developing new products. In addition, the AI independently recommends to customers when they should recycle in order to match internal demand and supply.

More about the winning project

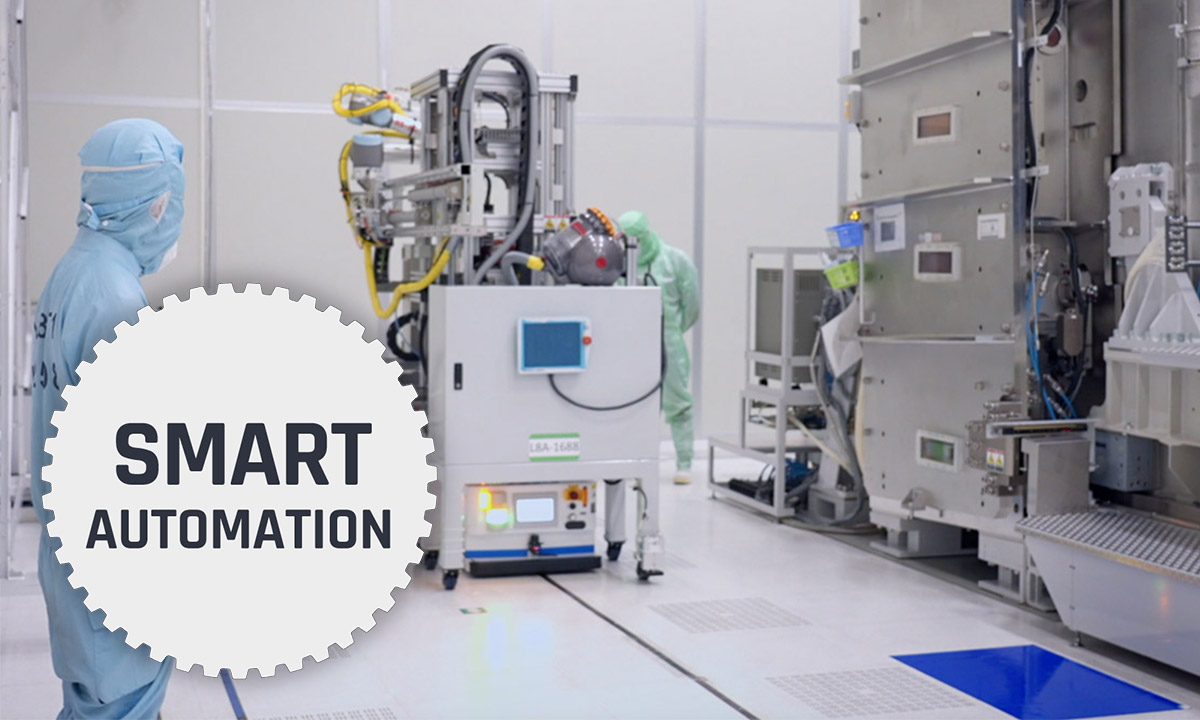

Winner in the "SMART AUTOMATION" category: AUO Corporation

To increase efficiency and reduce manual activities, as well as improve the environmental balance in manufacturing, AUO Corporation combines various digitization and automation technologies in a cyber-physical system (CPS) to support the store floor. The world's leading manufacturer of LCD flat panel displays can thus monitor more than 100,000 different process parameters in real time. They form the basis for applications such as AI-based visual quality control or improved resource management based on AIoT (Artificial Intelligence of Things) sensors.

More about the winning project

Winner in the "SMART WORKFORCE" category: EDGE Group PJSC

With a comprehensive Industry 4.0 program, the technology group EDGE laid the foundation for the optimization of numerous operations processes, from production orders to outbound logistics. In order to sustainably anchor the resulting new ways of working in the organization, the company established its own "Learning & Innovation Factory". It offers a comprehensive training program covering a matrix of skill levels and topics such as Lean & Lean Digital, Six Sigma, Analytics & IoT, and Agile, enabling employees to master the changes brought about by OPEX and Industry 4.0.

More about the winning project