- Improving cost reduction programs in terms of consistency, speed, and cost discipline.

- Optimizing inventory management and accounts receivable.

- Reducing procurement costs.

- Implementing holistic profitability programs.

Tailored strategies for sustainable product excellence

For the manufacturing industry in German-speaking countries, this means systematically renewing outdated organizational structures, business processes, mindsets, refocusing on innovation, industrial expertise, and reinventing them. To become truly become a global pacesetter in product excellence, several levers must be activated:

- Increasing agility and efficiency to keep pace with the speed, innovative strength, and financial power of new, aggressive competitors;

- Reducing product costs on a globally competitive level and reducing required CAPEX;

- Establishing lean and agile production systems and making intensive use of modern data-driven technologies and digital transformation;

- Implementing performance-enhancing approaches, systematically developing competencies, and accelerating implementation initiatives; •

- Building new supply chains and further developing the global sourcing and manufacturing footprint with a focus on market and cost efficiency;

- Fostering a culture based on personal responsibility, commitment, readiness for change, efficient and flexible decision-making structures, and an agile leadership mindset.

From idea to series production to end-of-life

We support companies on their path to product excellence – from the initial idea through to series production and ultimately to end-of-life. We enhance performance, profitability, and innovative strength, implement initiatives to reduce product costs and increase revenues, help avoid costly mistakes, and shape global footprints, production systems, and leadership models with a future-oriented mindset – all with the goal of sustainably improving competitiveness.

Depending on the specific customer situation, we develop individual end-to-end approaches. The objectives: rapidly stabilizing the company’s liquidity position, achieving stability through the optimization and flexibilization of cost and process structures, and driving sustainable value creation through profound initiatives at the levels of strategy, innovation, and market model.

To achieve this, we leverage a range of strategic levers:

Product cost optimization and EBIT improvement

R&D

- Establishing future-oriented operational and organizational models for product development.

- Making development teams more agile and fostering cross-functional collaboration.

- Increasing the efficiency of development processes.

- Implementing Design-to-Cost principles.

- Using automation, AI-driven technologies, and modular digital platforms.

Supply Chain

- Enhancing supply chain resilience.

- Implementing strategic and digital sourcing concepts such as vertical integration and nearshoring.

- Developing solutions for dealing with volatility and disruptions.

- Further developing the global footprint and supplier management.

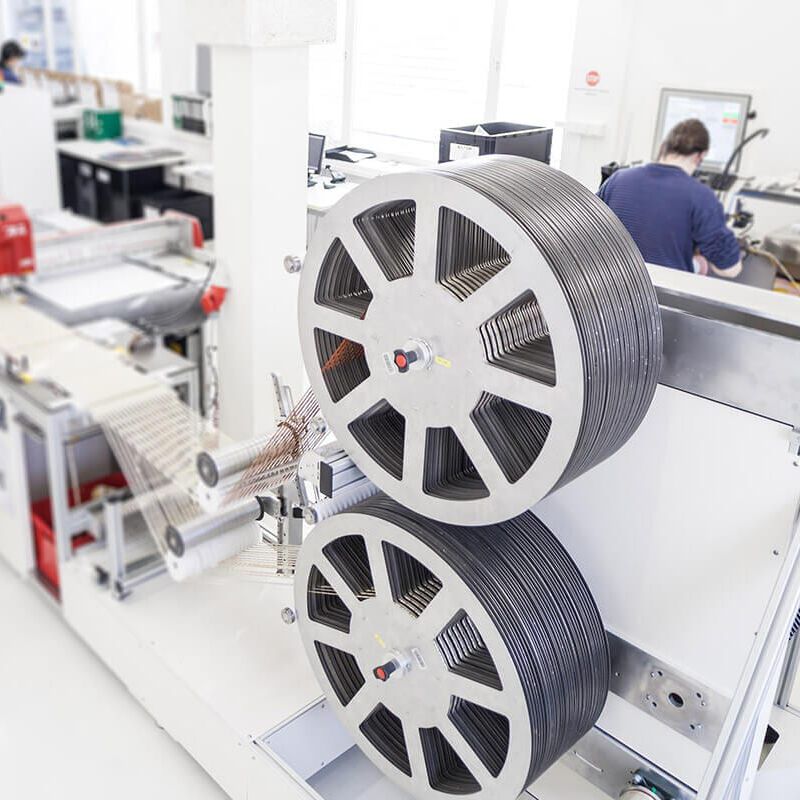

Production

- Maximizing the use of existing production capacities.

- Increasing output without additional investments through the use of video analysis, software-based machine tuning, automation, and AI-driven solutions such as digital twins and predictive maintenance.

- Implementing holistic product profitability initiatives for series products.

- Improving performance and avoiding disruptions in production.

- Introducing lean approaches.

Product Portfolio

- Ensuring profitability from early development to product launch.

- Reducing complexity through intelligent product architecture, modularization, and variant management.

- Increasing product profitability for series products.

- Optimizing the Product portfolio and go-to-market strategies.

- Ensuring smooth product launches.

Sustainability & Compliance

- Reducing CO2 and other climate-damaging emissions and lowering energy consumption.

- Complying with regulatory requirements for products and services (e.g. MDR, FDA, IT security).

- Taking advantage of regulatory incentives and funding opportunities.

Leadership

- Systematic empowerment and development of employees.

- Creating high transparency and efficient, agile, and decentralized decision-making structures.

End-to-end solution portfolio for product excellence