- Assessment of the status quo of maintenance excellence and the level of digital maturity in maintenance.

- Identification of areas for improvement, pain points and evaluation of potentials.

- Definition of optimization measures and design of an implementation roadmap.

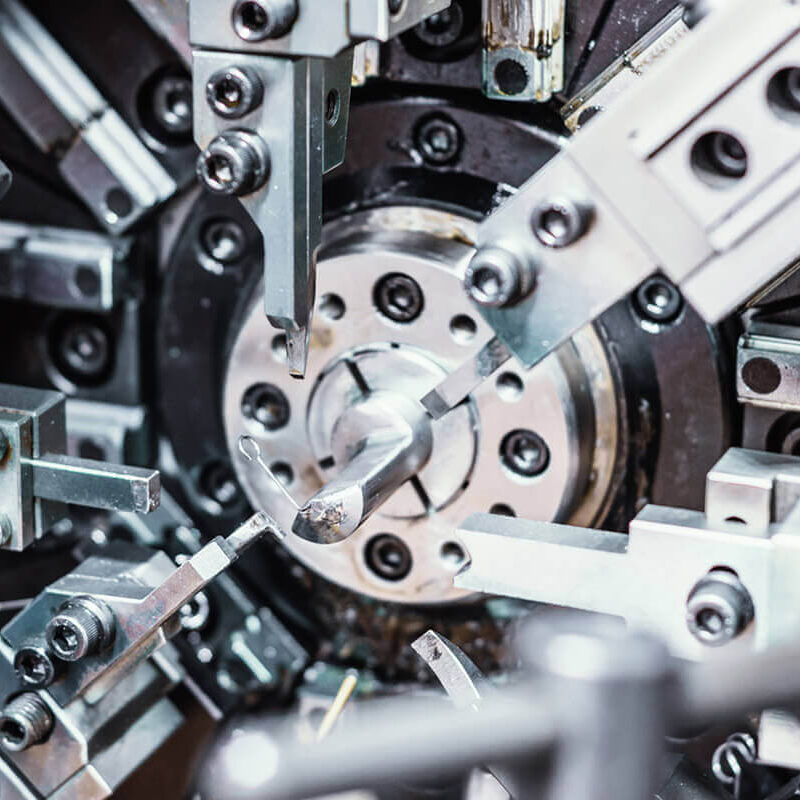

INCREASE OEE AND REDUCE MAINTENANCE COSTS

MAINTENANCE EXCELLENCE

Maintenance Excellence makes a significant contribution to reducing costs or preventing them in the first place. This improves the efficiency and effectiveness of maintenance processes and increases plant availability. Fruitful starting points for improvements are, for example, the use of mobile maintenance technologies, predictive maintenance and targeted employee training.

Overall, maintenance excellence results in a longer machine service life, lower operating costs and higher productivity - and thus strengthens companies in terms of profitability and competitiveness.

Take advantage of EFESO's expertise to achieve excellent availability and OEE (Overall Equipment Effectiveness) of your machines and systems at low maintenance costs. Realize systematically potential savings and further opportunities for improvement in maintenance - depending on your needs, we will focus on these areas:

Results

Companies achieved these improvements with EFESO in maintenance excellence projects:

Project "Maintenance Boost": Compensation for significant deviations in maintenance costs and OEE values that existed between individual plants of the company despite identical products and production processes.

Approach:

- Transparency / comparability of maintenance processes established in each plant.

- Cost and performance-critical elements identified and immediate measures defined.

- Group-wide maintenance system and plant-specific development plans created.

Results:

- Response times significantly reduced.

- Maintenance processes made much more efficient.

- OEE values significantly improved.

- Overall maintenance costs greatly reduced.

OPTIMAL MAINTENANCE PROCESSES WITH EFESO

Increase the maturity level of machine and plant maintenance. We ensure results in four steps.

1. Maintenance Excellence Analyse

2. Planning and initiation

- Creating the foundations for the transformation of maintenance with the responsible employees in the company.

- Initiating implementation in pilot projects.

3. Implementation and rollout

- Completion of the initiation of pilot projects.

- Enabling the maintenance team in the company to roll out the measures throughout the organization.

MORE SERVICES