- EFESO Management Consultants

- Competences Manufacturing and Logistics

Management consultancy for manufacturing and logistics

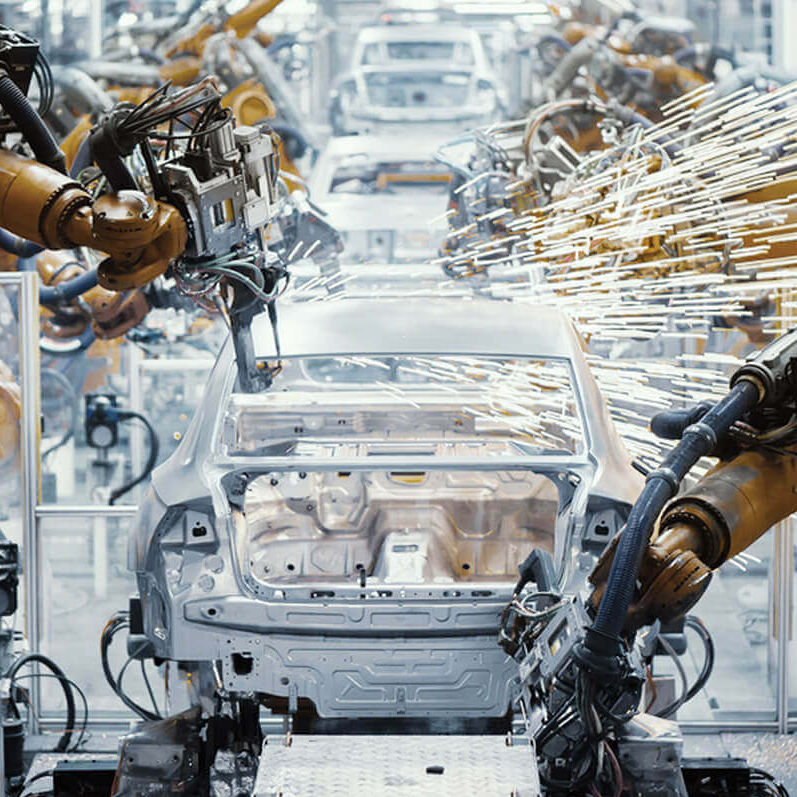

The global manufacturing and logistics network is the operational core of every industrial company. In order to be able to react flexibly to both continuous and abrupt changes in market and customer requirements and to grow profitably at the same time, a permanent and controlled further development of the production systems is necessary.

This requires strategies and concepts that focus on process excellence, cost efficiency, innovation, a lean, customer-oriented organization and consistent digitization. This is the basis for manufacturing and logistics networks to make their contribution to securing the long-term competitiveness and profitability of a company.

This task is more than demanding. The manufacturing strategy must be derived from the corporate strategy and operationalized, the cost structures must remain lean while increasing flexibility, the opportunities arising from technological development and Industry 4.0 must be used in a targeted manner, and the increasing complexity must be mastered and reduced at the same time. In addition, employees must be qualified and empowered so that they can perform these tasks with confidence.

This requires a perspective that encompasses every relevant aspect of the industrial value chain: from strategic decisions and the development of the global production map (Global Manufacturing Footprint) to technologies, systems, processes and qualifications in the factory and the supplier network.

The consultants of EFESO are the most recognized specialists for industrial transformation and best practice design of manufacturing and logistics.

Our comprehensive methodical know-how, technical and industry expertise as well as detailed knowledge of the relevant technologies, concepts and best practices around LEAN and Industry 4.0 make us an ideal partner in this demanding environment.

In detail, our range of services in the field of production and logistics covers the following topics:

- Operational Excellence

- Next Gen OPEX

- Lean Manufacturing

- Shop Floor Management / Digital Shop Floor Management

- TPM & OEE Increase / Maintenance Excellence

- Quality and process stability

- Smart Factory / Future Factory

- Factory and Layout Planning / Best Practice Assembly and Logistics

- IT management in manufacturing

»A high level of expertise, experience, and goal orientation characterized the collaboration with EFESO Management Consultants. This was the only way to successfully implement KOSTAL's global lean transformation program and generate practical benefits for our sites. As an essential component of the transformation program, new production and shop floor management systems were developed, implemented, and anchored globally for KOSTAL. As the basis for the design and continuous improvement of our value streams, it demonstrates the consistent added value of the effective collaboration between EFESO and KOSTAL.«

»The cooperation with EFESO Management Consultants was consistently positive. The development of a global training program was professionally prepared, specifically individualized, and designed to meet the company's needs. The global network enabled a parallel introduction at several global locations and was guided by a great deal of commitment on the part of the consultants. The consultants used technical expertise profitably and utilized it transparently and openly in training. It was ensured that EFESO also used globally standardized training methods and content, which was implemented successfully for the most part. In addition, the program was continuously developed even after its initial introduction to implement the vision of the training program sustainably. We would like to take this opportunity to thank you once again for your dedicated, professional, and positive cooperation.«

»Lean management is still one of the key philosophies in the 21st century. With the EFESO we had been able to improve our material flow efficiency dramatically. I really appreciate their ability to gap the bridge from creating an idea to realization. EFESO empowered our project with ideas and structural approach to get it done very fast without leaving our team members alone.«

»Together with EFESO, we achieved with the “Frische Brise” project sustainable productivity and efficiency increases in operations by implementing a shop floor management system adapted to our needs. The EFESO consultants demonstrated hands on attitude, social skills and relevant experience to support us with lean management know-how built up and training. Their additional support to select a suitable management execution system to digitalize our production processes was very appreciated. Currently we are planning the rollout on the shop floor.«

CASE STUDIES & INSIGHTS - PRACTICAL EXAMPLES

Blueprint for the Sustainable Factory

CASE STUDY:

A global supplier for the textile industry sets new standards in the sustainable design of its production facilities. EFESO accompanies the construction of a new factory in Bangladesh as a sparring partner and identifies together with the client potentials to reduce the use of resources and CO2 emissions as well as to increase workplace attractiveness. The result is a lighthouse factory that serves as a model for other factories of the company in terms of social and ecological sustainability.

Sustainability update for the global production network

CASE STUDY:

In order to achieve the sustainability targets it has set itself, an automotive supplier must optimize its more than 70 existing plants worldwide in terms of emissions and resource consumption. Together with the customer, EESO develops an overarching target picture to evaluate the maturity level and derive a sustainability roadmap for all sites.

Digital transformation in the food industry

CASE STUDY:

The EFESO case study describes how a confectionery manufacturer is expanding its competitive position with a comprehensive digitalization initiative. With EFESO, it is expanding the successes already achieved by its WCOM (*World Class Operations Management) program in the direction of highly digitalized production.

OPEX / WCOM for brewery group

CASE STUDY:

An international brewery group achieved significant OEE improvements in a WCOM pilot project with EFESO. EFESO's case study describes how this success was continued throughout the company's global value network, leading to improvements and savings.

OPEX / WCOM program at a market leader in the packaging industry

CASE STUDY:

A packaging manufacturer is strengthening its competitiveness against new market players. In doing so, the group is focusing on economically and ecologically profitable management in line with the “zero-loss” philosophy. With EFESO's WCOM™ approach, the company improved the detection, elimination and prevention of losses in 24 plants. At the same time, it empowered thousands of employees to pursue and realize Operational Excellence (OPEX).

On the road to digital excellenz

CASE STUDY:

The EFESO case study describes how a chocolate manufacturer started its digital transformation with EFESO. The goal: to activate potential in production and logistics to increase efficiency. The project team laid the foundations for this with a group-wide digitalization strategy and a roadmap for its implementation in several plants around the world.

Restart for Greenfield Planning

CASE STUDY:

An electronics manufacturer aims to secure a leading position in a future market in the Middle East with a new greenfield plant.

Together with EFESO, the company challenges the existing layout and concept – even though construction has already begun. With a digital building and process twin, the planning process is successfully restarted – despite the extremely tight timeline.

Transformation without limits

CASE STUDY:

Unlimited transformation: How a unified manufacturing system connects 50+ plants

Staying competitive despite global disruptions, labor shortages, and rising cost pressure? For an international automotive supplier, the answer was clear: only a bold new start could deliver the clarity, speed, and impact needed. Together with EFESO, the company developed a globally standardized manufacturing system—and unlocked the OPEX potential of over 20,000 employees in record time.

One Operations Community: strong performance on every playground

CASE STUDY:

A chemical group realigns its global production organization following a joint venture. The aim: to increase performance and efficiency worldwide. EFESO creates a “One Operations Community” in twelve plants - and over 230 improvement projects already generate savings of over EUR 120 million in the implementation phase.

Quality improvement in the automotive industry

CASE STUDY:

A leading global automobile manufacturer wanted to mobilize and accelerate its entire network of nine factories in terms of costs and quality. With EFESO, the group established a completely new, soccer-inspired practice of competing for a championship lead. The project team thus dynamized rigid factory structures and work routines.

OPEX: Worldwide Operational Excellence Initiative

CASE STUDY:

The EFESO OPEX model: activate the forces of excellence. You learn from mistakes. It is important that continuous improvement is the result. In industry, this is targeted as "Operational Excellence", or OPEX for short. Instead of resorting to off-the-shelf solutions, companies should develop their own strategies here - like the group from the steel industry, which successfully used the OPEX model from EFESO in its plants.

Standards for operational excellence in an international factory network

CASE STUDY:

Do you speak OPEX? Can you improve on a success story? Certainly, if you have a sense for the right fields of action. An automotive supplier is well-established worldwide, with around 20 successful plants in Asia, Europe and North America. Thanks to good customer proximity, the sites have developed good business relationships over the years and organised their production processes independently. But now it was time to share this knowledge among themselves. The method: by introducing OPEX (operational excellence) together with EFESO across the entire operation area.

Cost reduction/restructuring due to market changes

CASE STUDY:

A plant and mechanical engineering company had to ensure its competitiveness. EFESO identified all the adjustment screws for the necessary changes at a production site in Germany and got the turnaround going with a multi-layered restructuring approach.

Factory of the Future

CASE STUDY:

Special plant construction is a volatile project business with the smallest batch sizes, individual customer requirements and high complexity. Conflicting entrepreneurial goals of those involved make it difficult for companies to plan. In this complex market, EFESO developed a tailor-made factory of the future for a manufacturing company in order to increase the quality of the products, reduce costs and make projects more plannable.

Reduction of complexity through standardization

CASE STUDY:

In China, the "made in Germany" label stands for innovative strength, quality and a high level of development competence on the part of the manufacturers. A textile machine manufacturer wanted to reduce the variance and complexity within the Product portfolio. The main goals: reducing costs and strengthening the position in the Chinese market. With the China expertise of EFESO, a solid, regional supplier network was created in a short time.

Lean Training / Shop Floor Management

CASE STUDY:

Lean practice on the hall floor. With the EFESO lean training program, an industrial group improved its value-added processes at over ten locations. The program not only brought the different levels of knowledge of the managers in Lean Thinking down to a common denominator. With a multiplier approach, it also transferred the theory directly into work practice on the hall floor - from the first day of training.

Quality in production

CASE STUDY:

The highest quality standards are an indispensable part of day-to-day business in the pharmaceutical and life sciences industry. A medical technology company wanted to reduce the number of errors in the production line of one of its top products by a factor of 10. Together with EFESO, the company identified the right starting points and ensured quality increases that can also be scaled to other product lines.

Lean Digital Manager

CASE STUDY:

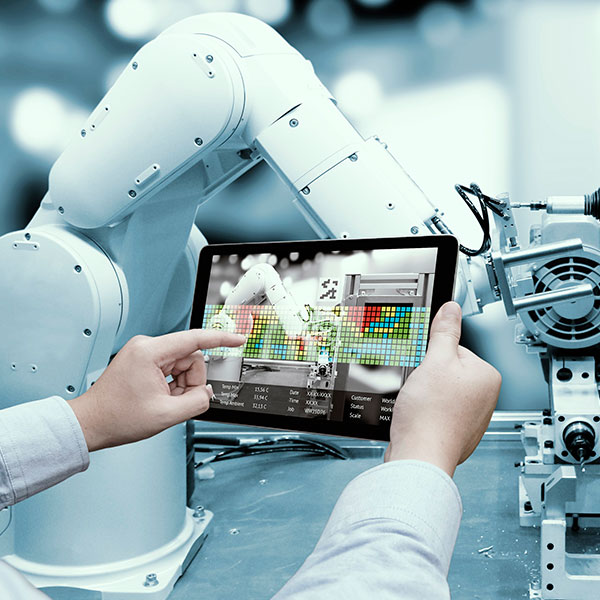

Shaping the factory of the future with Lean 4.0. How can lean principles be combined with the technologies and possibilities of networked digitization in value creation networks? By further qualifying employees to become decision-makers. The EFESO certification program for "Lean Digital Manager" shows how digitalization of lean production works. To do this, it combines strategies with Industry 4.0 technologies.

Digital Shopfloor Management

CASE STUDY:

Performance increase on the shop floor. Should every employee receive shift planning via smartphone? Or the plant management can compare solution proposals on a virtual dashboard in real time in the event of disruptions in the production flow? Thanks to the available IoT technologies, these and many other work simplifications of a digital shop floor management can be easily implemented today. Automobile manufacturers in particular like to take advantage of the opportunities offered by digitization and already have various systems in use, at all stages of maturity.

![[Translate to English:] Warehouse 4.0, Intralogistik 4.0, Logistik](/fileadmin/user_upload/intralogistik-2030-roi-beratung.jpg)

Intralogistics: Outlook into 2030

CASE STUDY:

Technological landmarks for ideal logistics: Technological landmarks for ideal logistics. Does a data goggle speed up picking? Or is an investment in a pick by light system more worthwhile? Up to now, new technologies for intralogistics have not been high on the priority list of companies. This is because the cost share of logistics is lower than that of other work areas and their need for digitization is generally greater.

Smart Factory Planning: Smart Planning for smart Factories

CASE STUDY:

What does the ideal factory of the future look like? Do products there control their production completely independently? A pharmaceuticals and life sciences company plans the main directions for the smart factory transformation of four plants in just one month. Together with EFESO, the project team creates a "big picture" as a basis for planning and tests three prioritized technologies in pilot projects.

Lean Transformation: Premium processes instead of fire fighting

CASE STUDY:

In the lean production system of an automobile manufacturer, a premium model with a wide range of variants and vertical integration rolled off the assembly line. But then the new head of production set the goal of introducing two additional series on the same line within just five months. The company used this challenge to realign its production, increasing the volume of manufactured cars by 85%.

Manufacturing Excellence: Optimizing instead of improvising

CASE STUDY:

The global demand for thermosets is increasing, as is the case in the energy industry. A manufacturer of thermosetting resins has positioned itself as a leader in the chemical industry by providing these customers with a variety of innovative technologies, solutions and specialty products. In order to be able to react even more efficiently to market changes and customer requirements in the future, the company is realigning its production network.

Target image for the transformation to Smart Factory

CASE STUDY:

End-to-end supply chain digitalisation in the healthcare sector. Putting together and ordering the desired product according to your own needs at the click of a mouse in the online configurator: these customer requirements must not only be met by companies in the consumer goods industry. This interaction is also highly relevant for manufacturers of medical, customisable products. However, whether assistants, support stockings or other products expand the B2C business in this way depends on the digital maturity of the logistics and production processes.

Factory and logistics planning

CASE STUDY:

An automotive supplier consolidates four parts warehouses into one warehouse. Three distribution centers of a company from the automotive industry should be integrated into an existing fourth. With the support of EFESO, the company mastered this task in eight weeks. To do this, it developed five solution scenarios with different degrees of automation (“minimal invest” to “fully automated”) including layouts and monetary evaluation.

OPEX: Redesign of the organization

CASE STUDY:

The demand for high-performance plastics is increasing worldwide. A company in the chemical industry wants to increase the total capacity of its polymer production by more than 50% with a new plant complex. Together with EFESO, it is aligning its organizational structure to growth and profitability and is realizing an annually recurring benefit of more than EUR 1.5 million through process improvements.

Lean Shopfloor: 'Fresh Breeze' for process efficiency

CASE STUDY:

A manufacturer of cosmetics and personal care items responds quickly to customer requests. High product demand leads to production bottlenecks at a market leader in the personal care industry. Together with EFESO, the company implements a complete shop floor management system - and increases output by up to 30%, depending on the line, with measures such as increasing the filling system cycle.

Production planning and control

CASE STUDY:

An automotive supplier harmonizes production planning and control in ten factory locations around the world. With EFESO, the company develops a suitable solution concept for a suitable software solution. This enables a standardization of the planning process and thus more flexibility and efficiency. Likewise, a long-term capacity planning of the plant group can be carried out in the new software.

Increasing productivity in the medical technology industry

CASE STUDY:

A fast-growing manufacturer of medical consumables can no longer meet the rapidly increasing demand and is threatened with the loss of market share. The company needs a solution to significantly increase output in a short time.

Chemical company on the way to climate neutrality

CASE STUDY:

In order to achieve the self-imposed goal of being climate-neutral by 2050, a manufacturer of basic chemicals has to put its entire business model to the test. EFESO supported the client with robust scenario planning to develop a sustainability roadmap that enables sustainable growth in a challenging industry environment.

Safeguarding the site thanks to lean value streams

CASE STUDY:

With hard targets for the entire operations area, a valve manufacturer is aligning a plant location for the future - and thus securing the site in Germany. Together with EFESO, the company restructures its manufacturing and logistics and achieves, among other things, an OEE of more than 85%.

Sustainable Chem: New start for the organization

CASE STUDY:

In order to achieve the self-imposed goal of being climate-neutral by 2050, a manufacturer of basic chemicals has to put its entire business model to the test. EFESO supported the client with robust scenario planning to develop a sustainability roadmap that enables sustainable growth in a challenging industry environment.