Our services for increasing productivity in business

In our projects to increase productivity, we first take a close look at the specific working environment of our customers, both in direct and indirect areas. In this way, we build trust and encourage management and employees to embrace change. This creates a clear basis for recognizing and quantifying measurable improvements and successfully implementing them together. Increased productivity must always be reflected in a clear and measurable improvement in results.

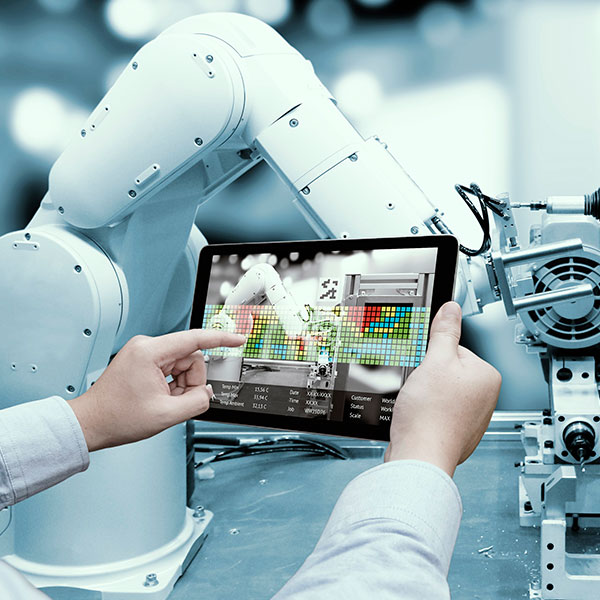

We have been building up the necessary expertise for many decades in challenging projects and programs with many different companies. Our range of tools is constantly being expanded with the latest specialist insights, new methods, and pioneering technologies.

This results in unique added value for our clients: experience and success drivers from hundreds of international projects are incorporated when we enable and support companies and their employees to make their business more productive and sustainable. Our consulting services address the following key areas:

Securing project success

Our experience shows that real, i.e. long-term, stable changes in behavior cannot be brought about by actionism, nor can the measurable increases in performance resulting from these changes. Success does not happen by chance – it requires a systemic approach combined with intensive support and supervision. The three main principles of productivity show us the way:

- "You get what you measure!“

- "Plan your work and work your plan!“

- "You can only control the whole if somebody also controls the detail!“

We ensure sustainable success by implementing these key principles in the form of productivity management systems. In addition, we assume joint responsibility for the realization of improvements with our performance-based fee model.