- Innovation & Development Strategy

- Digital product development

- Smart Products & Services

- Product Lifecycle Management (PLM, ALM, BIM)

- Product Value Management

- Agile Product Development

USING DIGITALIZATION TO DRIVE PERFORMANCE

DIGITALIZATION EXCELLENCE

Mold your operations processes more resilient, sustainable and results-oriented. With EFESO, you manage the digital transformation of your company successfully: from increasing the performance of machines and systems in the plant to more efficient, cross-functional collaboration and further productivity increases in the value chain.

Together, we identify value creation potential by considering the current maturity level of digitalization and automation as well as the market environment. We create an end-to-end overall strategy, that is operationalized with local target images and roadmaps.

From our point of view, "digital excellence" does not depend on technological tools. It is also about empowering employees to use these technologies effectively and efficiently. In this way, the performance of the organization can be strengthened and continuously developed. With EFESO, you can implement digitalization programs with the following priorities:

Results

Companies achieved these savings with EFESO in digitalization excellence projects (selection)

MASTERING DIGITAL TRANSFORMATION

Digital excellence enables companies to develop high-quality products and distribute them cost-efficiently. This makes a significant contribution to maintaining competitiveness in existing markets and opening up new business models in the context of digitalization.

With EFESO, you can identify the decisive levers for reducing costs and increasing performance in the context of digital transformation. Take advantage of our expertise in these key areas:

ADVANCED DEVELOPMENT

DIGITAL SUPPLY CHAIN

- Digital Supply Chain Strategy

- Global network simulation & optimization

- Advanced Sales & Operations Planning (S&OP)

- Order to Cash & delivery performance improvement

- Advanced Planning & Scheduling

- Digital Supply Chain Twin

- Supply Chain Control Tower

- Smart Logistics & Warehouse 4.0

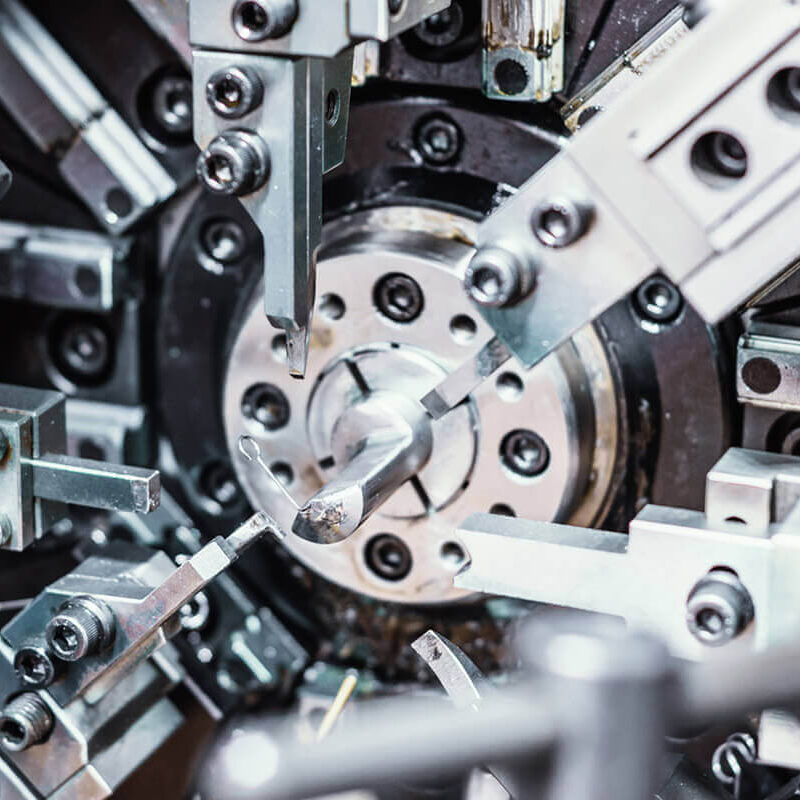

FUTURE FACTORY

- Flexible factory design

- Smart robotics & automation

- Modular machines & equipment

- Advanced intra-logistics

- Digital Factory & Process Twins

- Real time planning & control

- Integrated IT& OT-Infrastructure

- Leadership & Capabilities building

OPEX 4.0

- Digital Shopfloor Management

- Digital Operator support

- Digital enhancement of production systems

- Real time loss monitoring and eradication

- Governance & people mobilisation

- Digital OPEX platform

- Remote auditing & internal benchmarking

- Augmented reality & blended learning

MORE SERVICES