Machinery and Plant Construction

Tapping into growth markets and boosting performance with EFESO

worldwide in the past

three years

of industry expertise

reduction in material costs*

improvement in OEE*

Growth opportunities in international markets open up promising prospects for machinery and plant construction companies. In particular, technological innovations and increasing demand from emerging markets are boosting the industry. To expand existing customer segments and develop new business areas, two challenges are proving to be particularly critical to success:

Firstly, to quickly meet global demand from growth markets with competitive products, countries in Asia, Africa, and South America are investing massively in their industrial infrastructure. A strong local presence with a regional supply chain can pay off long-term through higher order volumes and expansion into other market segments.

Secondly, to make profitable use of automation and digitalization in the company and for the customer. The objectives: To increase efficiency, reduce costs, and improve product quality. The overarching goal is to develop solutions along the entire value chain from selective initiatives. Main segments are:

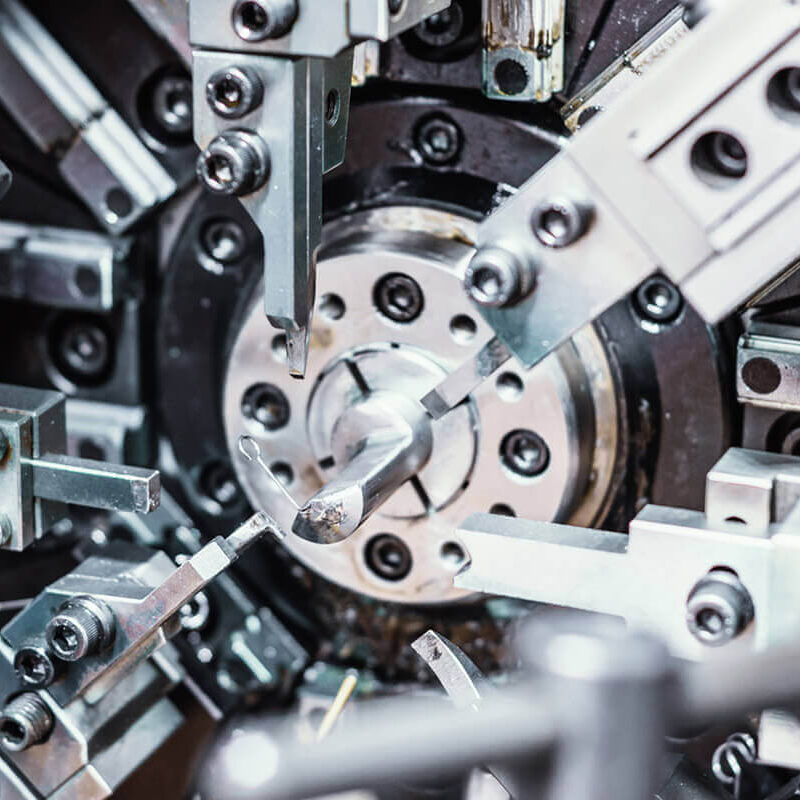

1. Machine tools and automation technology

Milling, turning, or grinding - machine tools form the core of every industrial production. Modern models work with maximum precision and can be integrated into digital production processes. This network provides real-time data on capacity utilization, maintenance requirements, and quality, enabling users to improve their production processes continuously. For manufacturers, this means shorter set-up times, fewer rejects, and more flexible production that adapts quickly to changing customer requirements – a competitive advantage in global markets.

2. Production facilities and assembly equipment

Production efficiency depends mainly on the quality and performance of the production facilities and the line equipment. Here, systems with intelligent control technology, adaptive robotics, and advanced sensor technology show how processes in the factory can be made faster, more stable, and more effective. At the same time, digitalization is driving forward the networking of tools with the value stream in the factory, so that, for example, downtimes can be reduced and set-up times optimized.

But it is also worth looking beyond the line: for example, when companies use digital twins of their machines and tools to plan and simulate production processes - thus determining the best way to implement them.

3. Machinery and systems engineering

New materials, energy-efficient drives, and digitally networked control systems can be used to develop systems that reliably support even the most complex production processes. This also meets customer demand for individually designed products and solutions.

Modular systems are playing an increasingly important role here. Supplemented by predictive maintenance, AI-based process optimization, and IoT technologies, optimum capacity utilization and the ability to react quickly to new requirements can be achieved.

Optimize capacity utilization and efficiency. Ensure quality. Shaping the future.

Improving the efficiency and effectiveness of industrial machines and systems

With EFESO, you can identify the levers for innovation, quality, cost awareness, and increased performance along your entire value stream. Our project experience from numerous international collaborations with manufacturers of production machines and assembly equipment combines strategy, technology, and implementation expertise. Together, we achieve measurable results in these and other areas:

- Balancing cost pressure: Establishing cost management is an essential prerequisite for profitability, for example, in the cost-oriented design of systems (Cost Value Engineering), procurement of components, and optimization of the value chain; developing into a high-performance organization (Zero Base Organization).

- Using digitalization as a performance driver: Development and operationalization of digital strategies; support in developing innovative products and services; conception, establishment, and further development of a company-owned „Smart Factory"; performance improvement with AI.

- Ensuring the transfer of expertise: Retaining specialist knowledge within the company and passing it on to new employees quickly and effectively; developing qualification programs for specialists and managers; setting up in-house academies and learning factories.

Find out more at the EFESO Academy.

Clients

Our industry focus in the "Industrial Manufacturing" segment

![[Translate to English:] ROI Case Studie - Digital Twin](/fileadmin/_processed_/6/1/csm_roi-casestudy-digital-twin_3c8c268a58.jpg)