Standards for operational excellence in an international factory network

Do you speak OPEX?

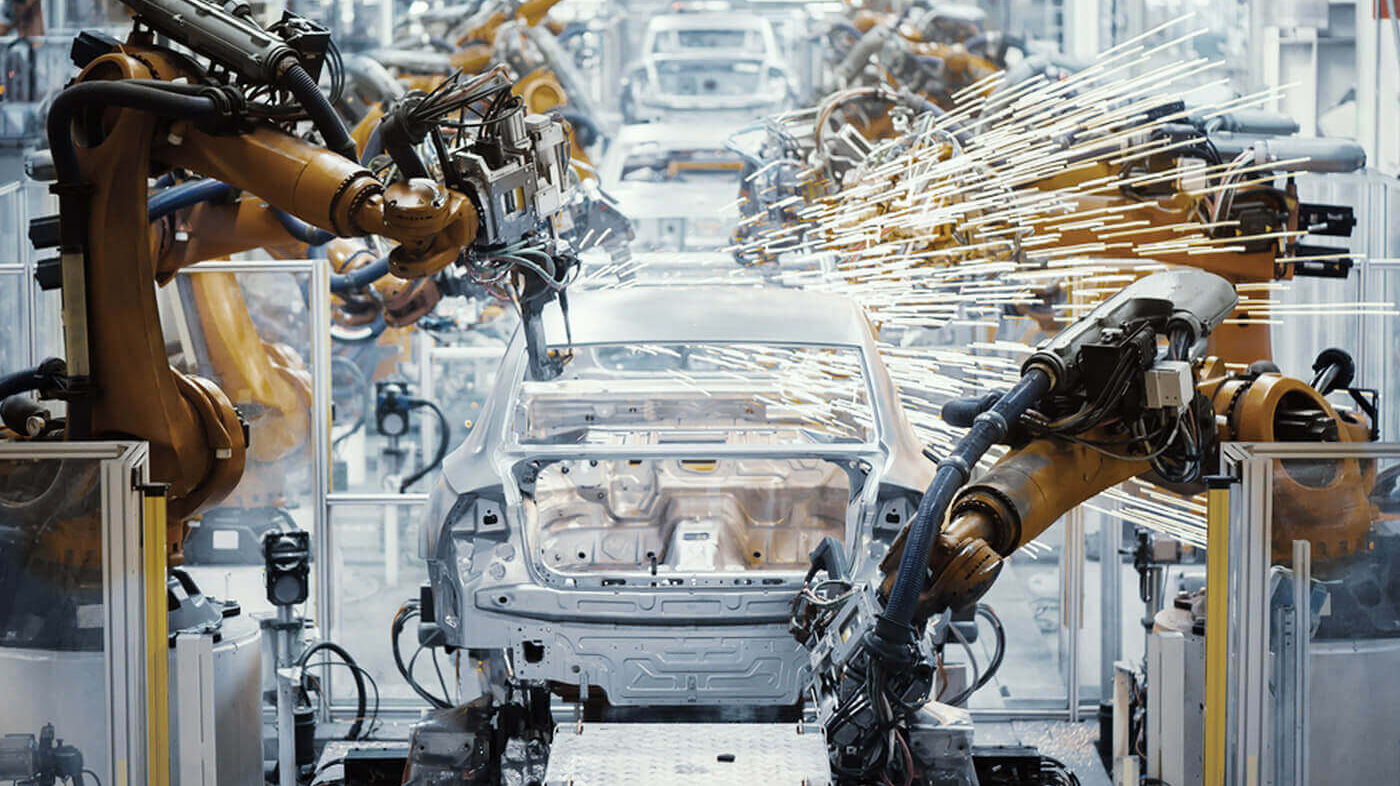

Can you improve on a success story? Certainly, if you have a sense for the right fields of action. An automotive supplier is well-established worldwide, with around 20 successful plants in Asia, Europe and North America. Thanks to good customer proximity, the sites have developed good business relationships over the years and organised their production processes independently. But now it was time to share this knowledge among themselves. The method: by introducing OPEX (operational excellence) together with EFESO across the entire operation area.

Challenge

Around 20 factories of a global automotive supplier were working largely independently of each other. In order to develop value-added potential with OPEX, it therefore had to create the conditions for OPEX to be introduced.

MOREEFESO approach

Using OPEX market stalls and playful learning forms, EFESO quickly helped to boost know-how acquisition and introduce structured operations processes that work at an international level. Commitment at all hierarchy levels and control of the measures ensures lasting success.

MOREEFESO success model

EFESO applies OPEX from the beginning of the value chain, makes practical experience tangible and ensures proper communication at all levels.

MOREUnderstanding the big picture

The operation area of the company covers around 10,000 employees worldwide. Before starting the project, the plants were extremely heterogeneous in their operational structures and processes from country to country. They also had very different approaches in dealing with technologies, such as automation/digitisation and the collection of key data. This significantly restricts performance comparisons between the around 20 plant locations, and cultural differences also raised barriers in cross-site exchange. For the project launch, the company, together with EFESO, had to establish the prerequisites for an OPEX introduction.

Promote exchange and motivation

To this end, an OPEX team was established consisting of the operations managers of the various countries and the Global Operations Manager of the Group. In a short time, they were able to achieve this important step: to motivate those responsible to engage in active, mutual exchange and to anchor this understanding, an essential component of a global value creation cycle.

Local stakeholder management

“Think globally, act locally” – in line with this slogan, by implementing consistent stakeholder management, EFESO also managed to eliminate the reservations and concerns of employees towards OPEX and to integrate the relevant managers into the comprehension process. During intensive dialogue and workshops, the EFESO team learned far more than just what the respective plants were focusing on in terms of organisation, processes, and customer relationships. At the same time, from the first day, they were able to channel the employees’ high level of willingness to learn and change into OPEX, for instance, by presenting best practice cases.

Supporting the functional areas

This quickly created a common view of the status quo and the project objectives in the OPEX team. The team agreed this ‘target image’ with all functional areas: production, purchasing and logistics also make their contribution, as do research and development, design and sales. At decisive meetings of the OPEX team, therefore, a corresponding manager from each plant took part, and there was always prompt coordination with the boards.

OPEX market stalls increase exchange of ideas

One significant success factor in this approach was to design the OPEX measures in the works to correspond to the information and communication conditions in the plants. For example, instead of PowerPoint presentations for visualising the OPEX-relevant information, the project team set up display panels with globally relevant indicators, which concentrated on time indicators or the value flow, among other things. In general, it was quickly seen that an original, creative approach is ideal for a lively and productive dialogue between managers from China, Japan, the US and Europe.

Experiencing the OPEX target image live

All factory managers, department managers and specialists from around the world met several times for three days at global operations conferences in order to not only discuss the measures necessary for implementing the OPEX target image but also to experience them live and in different roles with different tasks. For this purpose, the project team built ‘OPEX market stalls’ to illustrate the various thematic focuses. For example, there were different prototypes for the standard assembly line and the participants were allowed to ‘play through’ two different products on them. In this way, they experienced directly how the product change felt on the line and which specific changes it would be involved.

Exchanging roles as a playful learning method

In order to sensitise the plant managers to the way in which an early operation integration can change the entire value chain, they built a functioning toy car together using simple tools during the OPEX meeting. The key feature here was that a roll exchange was mandatory. The production manager stepped into the shoes of the purchasing manager, product development exchanged with sales, etc. Europeans exchanged roles with the Japanese colleagues, Chinese managers with American colleagues. The playful realisation was that without consensus the process does not run smoothly. Due to this common experience, the benefit of OPEX was not merely abstract. The team learned not only the basic OPEX rules, but also quickly recognised its added value – for example, to do the job better or to reduce interruptions due to quality problems over the long-term.

Guaranteeing the information flow

But how effective are these measures in practice? To find this out and to make any adjustments that might be necessary, EFESO conducted telephone interviews with randomly selected employees from all locations. A monthly newsletter and regular ‘town hall meetings’ support and accompany the pending change processes in the next project phase. In each plant, a drawing of the ‘factory of the future’ also helps to graphically illustrate all central OPEX measures.

Future prospects

After the first phase of the project, it is already evident that the managers in the works, but also the company’s board of directors, perceive operations as having a fixed size. Its creative force, never properly appreciated before, is now valued by all stakeholders. The collaboration between the functions within the sites and between the various factories has also improved significantly. The company wants to build on this success in the next project phase in three thematic areas:

- Performance management: Establishing a global shop floor management team to increase flexibility in the plants.

- Product development processes: The aim is to integrate these into production and operations at an early stage.

- Standardisation of global assembly technology: If the company buys a new factory somewhere in the world in the future, the line should work in accordance with global process and quality standards from the first day.