Cost reduction

With EFESO, industrial companies effectively reduce their costs in manufacturing, supply chain management and indirect areas, thereby strengthening their competitiveness in the long term.

We use tried-and-tested methods to reliably identify cost-cutting potential and transform this into P&L-effective measures.

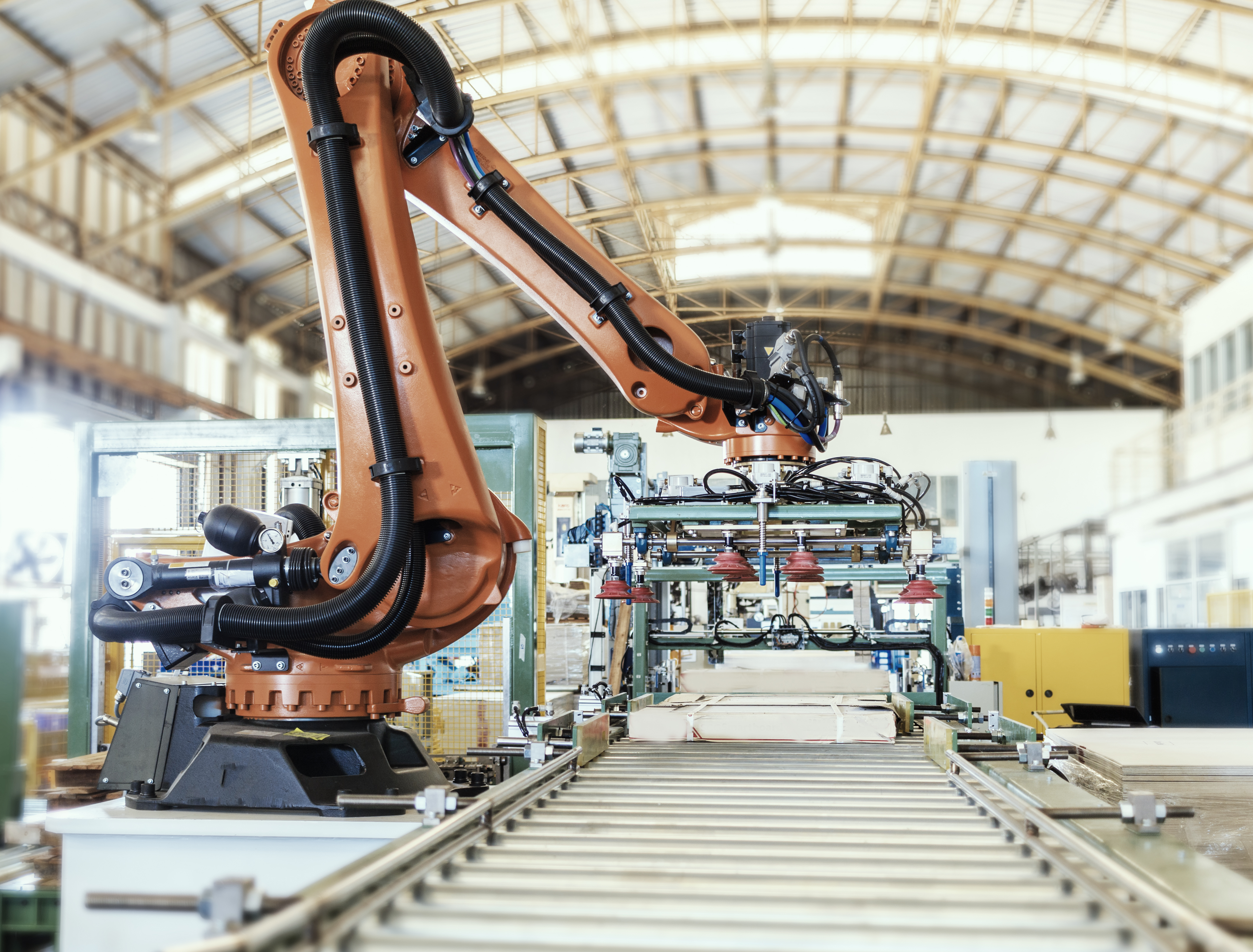

Digitalization, Industry 4.0 & IIOT

The EFESO consulting team works with companies worldwide to implement pioneering projects for industrial digitalization, Industry 4.0 and Industrial IoT.

We offer unique, multidisciplinary expertise with in-depth methodological and technological know-how – and access to the top benchmarks of industrial digitalization through our renowned INDUSTRIE 4.0 AWARD.

Operations Management: Effectively countering increasing cost and performance pressure.

Manufacturing & Logistics

EFESO is one of the most recognized specialists for the continuous improvement of processes in the core operations areas of production and logistics.

Repeatedly received, independent awards such as the "Hidden Champion" seal of quality in the "Engineering, Production & Industry 4.0" category confirm our expertise in technologies, methods and best practices relating to lean, OPEX / WCOM™ as well as industrial digitalization and automation.

Supply Chain Management

In cooperation with EFESO, supply chain management organizations build reliable value-added structures and develop them in a future-oriented manner.

Together we develop the right solutions for formulating and implementing supply chain strategies, optimizing supplier and risk management and other challenges in global and regional value creation processes.

Procurement

Material costs are the most effective lever that industrial companies should use to increase their profitability. Even small improvements in the areas of purchasing and procurement can be the starting point for significant improvements in results.

EFESO's team of experts knows groundbreaking best practices in procurement and supports companies in identifying and realizing potential savings - quickly and right through to implementation.

Operations Management: Consistent focus on value creation.

Operations Footprint

The globally active EFESO Group is represented in all major economic centers in the world. We work with companies to solve demanding challenges in their regional and/or cross-border value creation, so that a robust operations footprint is created.

Common focuses here are the improvement of production and logistics networks, the development and implementation of purchasing strategies and make-or-buy decisions.

Product & Service Development

Together with EFESO, R&D organizations become an essential value driver in the company: We support them in effectively and efficiently aligning value creation with the corporate strategy and positioning themselves for the future.

We achieve this with our international network of experts and the many years of cross-industry expertise of our operations teams in re-aligning and improving R&D organizations.

Transformation & Leadership

Supported by EFESO, companies create the framework for sustainable transformations, successfully design change projects and increase their individual potential – from the shop floor to the management level.

We encourage managers in transformation processes in leadership assessments, competency development and other challenges. At the same time, we enable the entire organization to determine and successfully implement goals in change management.

Industrial Sustainability

Companies in the manufacturing industry work with EFESO to establish value creation networks, factories and operational processes that are highly efficient, low-waste and low-emission, as well as circular and adaptive.

Our range of services is divided into the areas of "Sustainable Transformation", "Sustainable Products", "Sustainable Production & Operations" and "Sustainable Supply Chain & Footprint".

Operations Management: Excellent processes as a benchmark.

Productivity increase

EFESO supports companies in permanently increasing their productivity.

The range of services particularly addresses the topics of “growth”, “stabilization” and “restructuring and turnaround”.