TOPICS & NEWS

Articles and interviews on current trends, technology and industry challenges, information on our consulting services, seminars and events as well as company topics:

Here you can find out what drives ROI-EFESO.

ROI-EFESO presents the winners of the INDUSTRIE 4.0 AWARD 2022

Munich, November 28, 2022 - The INDUSTRIE 4.0 AWARD 2022 goes to AUO Corporation, EDGE Group PJSC, Mangelberger Elektrotechnik GmbH and RITTAL GmbH & Co KG. Since 2013, ROI-EFESO has awarded the renowned prize to Industry 4.0 solutions in the manufacturing environment that set new standards in digitization and automation. This year, the award jury selected winners in four categories from international applications.

Based on anonymous project descriptions, more than 30 high-caliber executives from the industries determined who is positioning themselves as an Industry 4.0 pioneer in the award categories "SMART FACTORY”, "SMART & SUSTAINABLE”, "SMART AUTOMATION" and "SMART WORKFORCE” with their current best-practice project or an already implemented solution.

Smart, green and holistic

Two trends dominated the applications submitted: On the one hand, solving new workforce management challenges for manufacturing companies. On the other, Industry 4.0 professionals are increasingly using their automation and digitization expertise to achieve sustainability goals, such as building a circular economy or improving their energy and materials management.

"Particularly exciting are projects that integrate customers and partners at an early stage to improve the economic and ecological bottom line beyond their own playground",says Hans-Georg Scheibe, Managing Partner at ROI-EFESO Management Consulting AG. "The Industry 4.0 solutions of this year's award winners exemplify how to successfully visualize and orchestrate manufacturing data and processes in this context."

INDUSTRIE 4.0 AWARD winners 2022 at a glance

Mangelberger Electrical Engineering Ltd.

Winner in the "SMART & SUSTAINABLE" category

Awarded for realizing a circular economy where AI and other Industry 4.0 technologies support the design and recycling of products.

EDGE Group PJSC

Winner in the "SMART WORKFORCE" category

Awarded for an Industry 4.0 project for digital transformation. A Learning & Innovation Factory qualifies employees to master changes through OPEX and Industry 4.0.

For more information on the competition and the winning projects, please visit:

"SMART FACTORY" Award goes to RITTAL

RITTAL GmbH manufactures control cabinets in its smart factory at the Haiger site. In the process, the award winner networks around 300 employees and 250 machines across all production lines by means of around 10,000 data points - and goes one step further. "We work from the customer to the machine control system on the shopfloor, so we have a continuous chain," says Jürgen Kromer, Vice President Production RKS at RITTAL.

All process steps from customer order to production to packaging and delivery are interconnected, integrated and, if necessary, automated. In the process, RITTAL also used Industry 4.0 tools to expand the employees' perspective beyond their own work area. This makes it easier for the entire team to understand the effects of process changes.

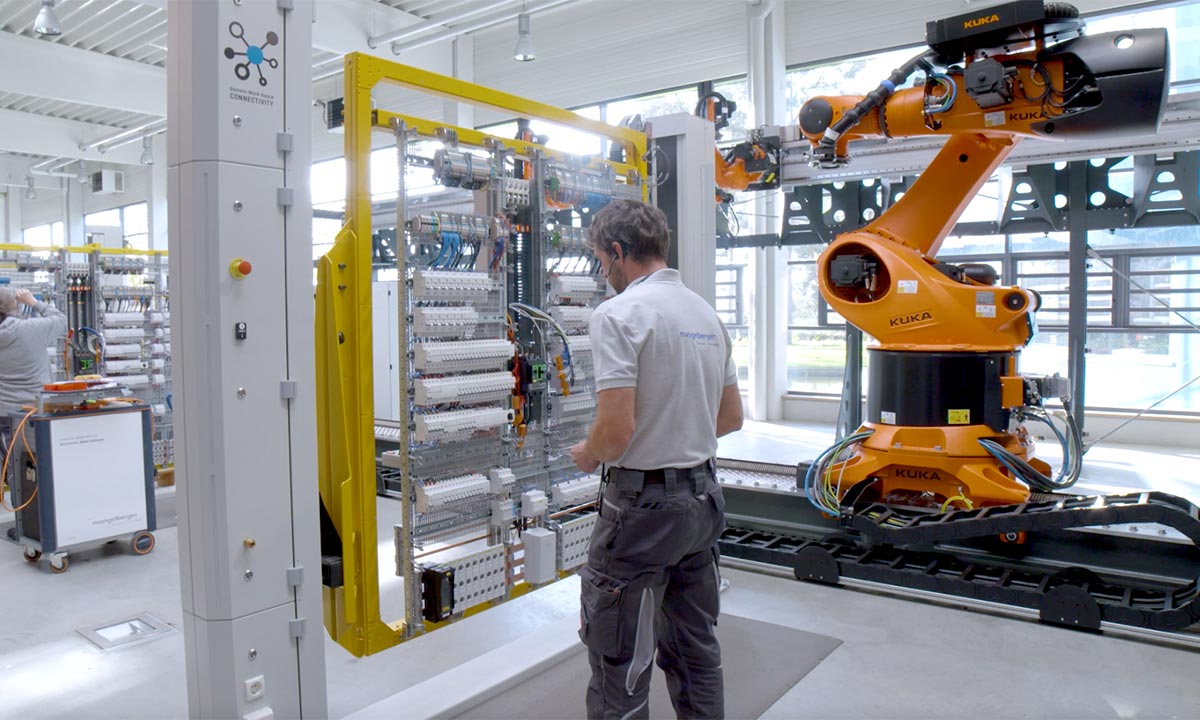

Mangelberger Elektrotechnik GmbH wins in the category "SMART & SUSTAINABLE"

With the award-winning Industry 4.0 solution, Mangelberger is automating and digitizing its value creation processes, in particular through the use of AI and digital twins. "We build control cabinets with brains - all consumption is recorded in a database", says Andre Polner, Project Manager for Plant Engineering at Mangelberger Elektrotechnik.

An AI analyzes the performance of more than 8,000 enclosures in practical use and uses this data to select the right components for new product development. In addition, the AI autonomously recommends to customers when they should recycle to match internal demand and supply. Already, 60 percent of the components that go into a new product come from repurchased and recycled control cabinets.

Show Mangelberger's winning project.

AUO Corporation awarded for "SMART AUTOMATION" solution

Taiwan's AUO Corporation is one of the world's leading manufacturers of LCD flat screens. In the award-winning Industry 4.0 project, the company combined multiple digitization and automation technologies at a plant in Taichung. "Our solution integrates Big Data analytics, intelligent automation operations, and our Cyber Physical System (CPS) to increase production yield and efficiency while reducing the environmental impact of display manufacturing", says CH Wu, Associate Vice President at AUO.

For example, the CPS enables monitoring of more than 100,000 different process parameters captured by machine data points, IoT sensors and other tools. The award winner benefits here in particular from effective data acquisition, data cleansing and AI modeling. One example of use is image recognition: Here, a camera-based AI checks the LCD panels in the production line and automatically sends defective products to a rework line.

EDGE Group PJSC receives "SMART WORKFORCE" award

Within two years, the technology group EDGE implemented an Industry 4.0 project for digital transformation that improved numerous processes from the management of production orders to outbound logistics. The company's own "Learning & Innovation Factory", or LIF for short, played a central role in this. Its training program covers a matrix of skill levels and topics, e.g. with regard to Lean & Lean Digital, Analytics & IoT and Agile.

In addition, the award winner achieved complete connectivity of the machines in its manufacturing and records all relevant data in an IIoT platform. This allows, among other things, calculations of KPIs such as OEE and the visualization of process parameters in real time in a digital shop floor management. Other features include condition monitoring of the machines, including predictive maintenance, and AGVs that fulfill their transport orders linked to the material consumption of the manufacturing processes.