Smart Transportation

By Dr. Wolfgang Keplinger, ROI Management Consulting AG

With the continuous improvement of diesel technology as the world‘s most important drive technology for lorries, the emissions per kilometre travelled have dropped significantly in recent years, but a non-practice-relevant determination of statutory emissions tests reveal gaps for manipulation or skilful interpretation of the law by the manufacturer. Moreover, the improvements could not offset the effect of the ever-growing route optimization program, despite the today’s widespread use of route optimization programs in the freight forwarding sector.

With the continuous improvement of diesel technology as the world‘s most important drive technology for lorries, the emissions per kilometre travelled have dropped significantly in recent years, but a non-practice-relevant determination of statutory emissions tests reveal gaps for manipulation or skilful interpretation of the law by the manufacturer. Moreover, the improvements could not offset the effect of the ever-growing route optimization program, despite the today’s widespread use of route optimization programs in the freight forwarding sector.

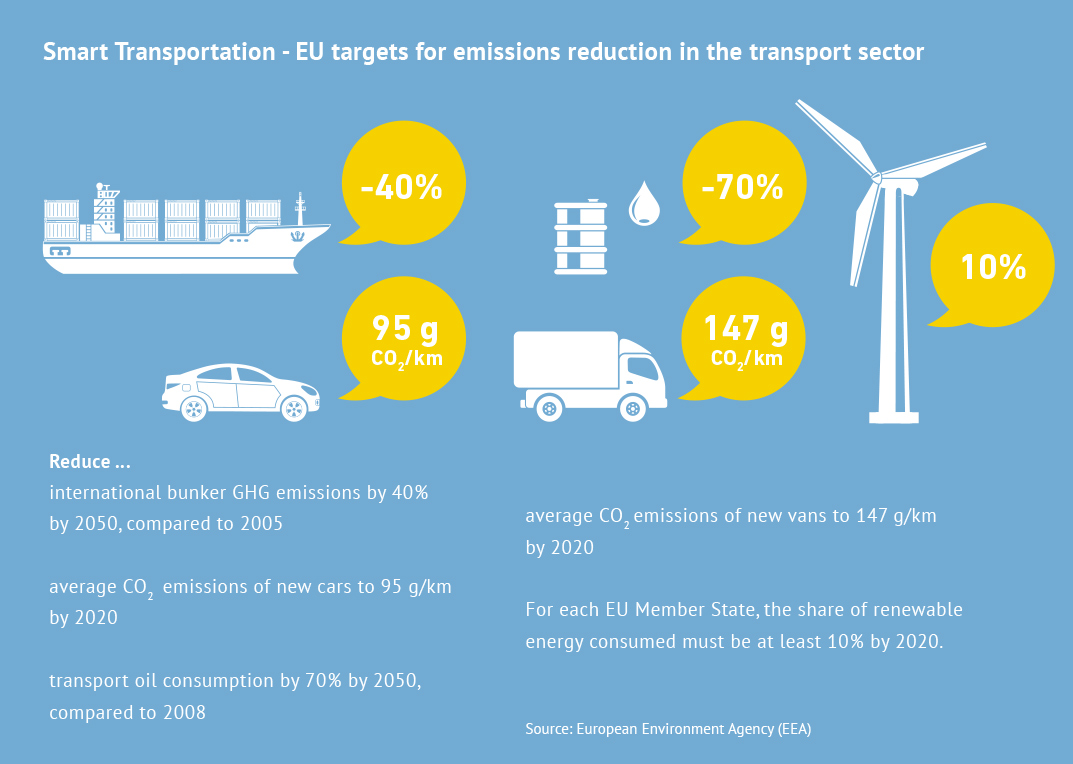

By leaving the Paris Climate Agreement, the US has abandoned the road to green transport logistics, strengthening a backward-looking trend towards fossil fuel use in other nations as well. But the next push towards really green transport logistics can only be expected if the state governments take the environmental goals laid down in the agreement seriously and the legal framework for transport and logistics is significantly narrowed. However, it is good to know that the necessary technologies or solutions already exist or will be ready in the near future. The most important expectations of green transport logistics currently include:

E-transporters in urban space

A pioneer in the field of small trucks and vans in Germany is DHL with the all-electric StreetScooter. Developed in 2010 from a research initiative of the RWTH Aachen Technical University, about 100 employees of the company, now owned by DHL, have been producing this urban delivery vehicle since 2014. In 2016, the 1,000th vehicle was manufactured, and now 10,000 are expected to leave the production line every year, with the end goal, among other things, of electrifying the total inventory of around 70,000 DHL delivery vehicles. In addition, there are already external prospects for the StreetScooter such as municipalities, dealers or craftsmen. Daimler has been using the Fuso Canter E-Cell since 2014, a light all-electric lorry in everyday use, which went into small series production as Fuso eCanter in 2017.

In addition, Mercedes-Benz presented the first all-electric truck for urban heavy-duty distribution transport of up to 26 metric tons and with a range of up to 200 km. This truck went into everyday use testing in 2017 and production could start in 2019/2020. Since the end of 2017 MAN has also been testing an eTruck concept for medium and heavy urban distribution traffic in everyday scenarios at the end of 2017. The advantages of this e-lorry are obvious: They meet the soon-to-be tougher urban requirements for emission-free driving and allow night-time deliveries in urban areas. With the increasing capacity of new battery generations as well as their continuous drop in manufacturing costs, these vehicles could soon come within range of comparable costs to today‘s diesel technology. Of course, in the best case scenario, their drive current should come from emission-free wind power or solar/photovoltaic energy.

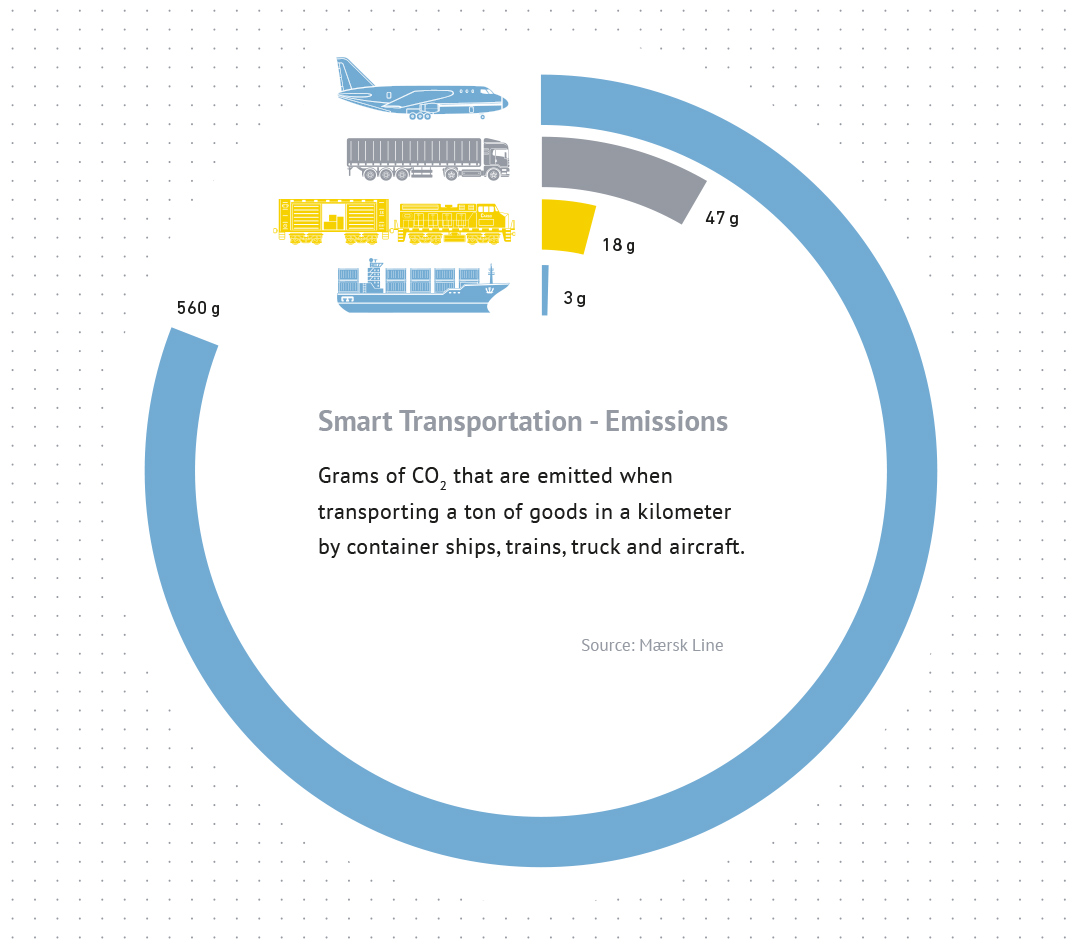

One of the biggest transport problems on the way to reduced CO2 emissions are the unused but moving cargo bays.

Platooning: sensor-based control of convoys of lorries

Even if the technological leap to pure battery operation is not yet possible for long-distance travel and heavy lorries from 26 to 40 metric tons, there are still interesting technological innovations, especially in the electronic, wireless sensor-based control of convoys of lorries. A study by the Massachusetts Institute of Technology (MIT) showed that closely spaced lorries consume up to 20 percent less diesel and less than half of the motorway surface in normal operation due to lower air resistance. Due to the short steering control reaction time, necessary braking processes can be triggered in just 0.1 seconds, which enables extremely short vehicle distances of only 10 - 15 m (less than the length of a lorry with trailer). Volvo and Daimler have completed their first platooning trials in 2016 and 2017. Just this year, DB Schenker and MAN announced a major platooning practice test in networked truck convoy operation.

Improved cargo space utilization through Big/Smart Data Analytics

One of the biggest transport problems on the way to reduced CO2 emissions are the unused but moving cargo bays. Of course, with constant demands for even faster delivery times, the cargo volume used cannot be optimized and improved at the same time. But above all, big data analytics can help to make unrealized but anticipated needs more predictable and combinable with current transport processes and to bring together the existing supply of cargo space with the demand at short notice.

Cargo Sous Terrain AG (CST) from Switzerland has developed a fascinating idea with the vision of a holistic solution for logistics. An automated logistics system enables underground transport of pallets and containers. Tunnels connect production and logistics locations with metropolitan areas. In the city, the CST’s goods are distributed efficiently and ecologically sustainable. The idea has already found numerous industry and community supporters and shows that cross-company, platform-minded approaches can really bring about substantial improvements in logistics.