We systematically evaluate top suppliers based on spend, value-add depth, technical relevance, and savings potential (Gap-to-BPG). Low-probability candidates (“dead horses”) are filtered out early. Supplier selection incorporates both quantitative analysis and qualitative factors such as technological maturity, innovation potential, and collaboration readiness. The outcome is a robust shortlist to drive subsequent modules.

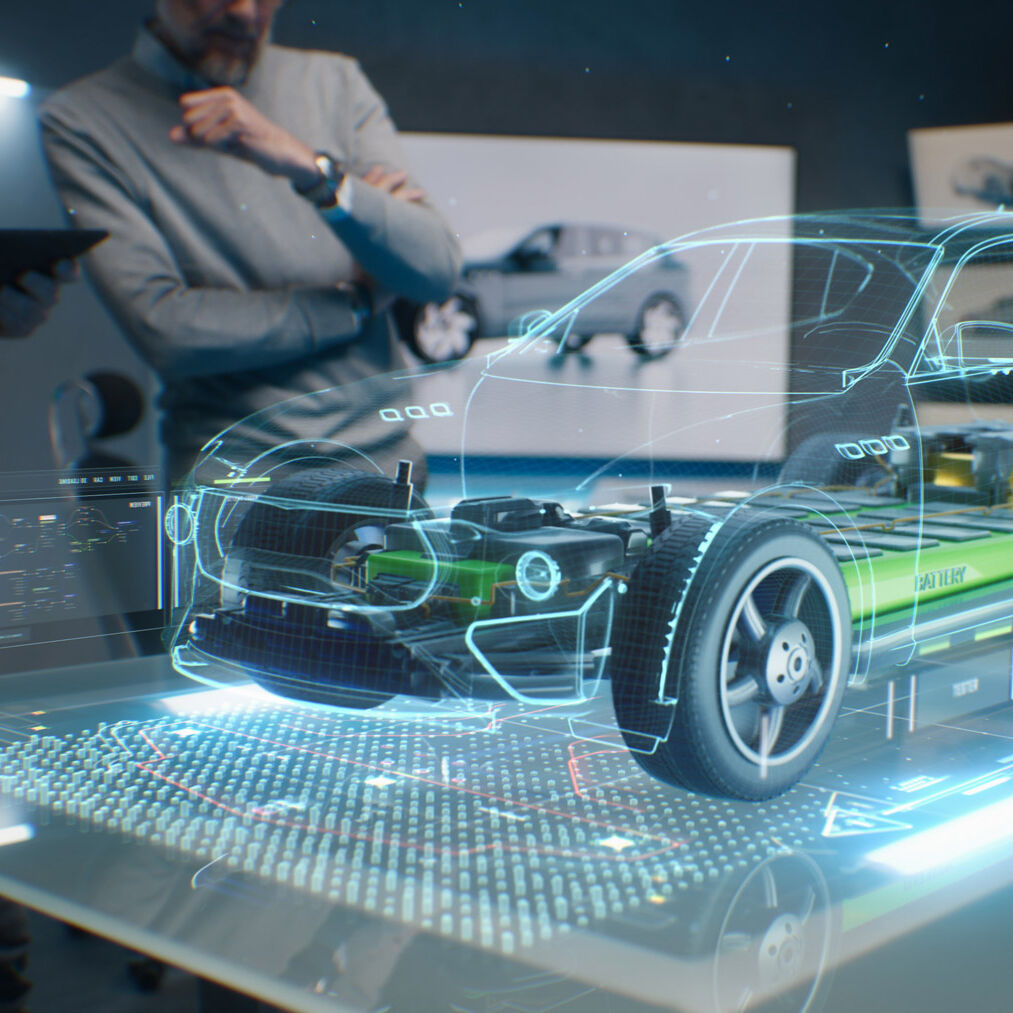

Supplier & Value Stream Optimization

in automotive, industrial,

off-highway & more

in savings achieved

through supplier benchmarking and technical optimization*

through cross-functional benchmarking*

Global supply chains are under continuous pressure from rising costs, shifting market dynamics, and increasing innovation demands. Common challenges faced by industrial companies include:

- Growing cost and price pressure driven by volatile markets

- Lack of transparency in suppliers’ cost structures

- Limited integration of supplier-led innovations

- Underperformance or low productivity among key suppliers

- Weak implementation of cost-out initiatives

Many manufacturing companies focus primarily on improving internal efficiency, often overlooking that a significant share of value creation occurs externally — within the supplier network. In some industries, external sourcing and supplier contributions account for more than 70% of total costs. Yet, visibility into supplier cost structures remains limited.

To stay competitive, companies must strategically develop and manage their supplier base — not only in terms of cost and quality, but also innovation, flexibility, and resilience.

Strengthen suppliers. Enhance value creation. Reduce costs.

EFESO’s Approach to Supplier & Value Stream Optimization

Our structured consulting approach helps industrial companies position suppliers as strategic partners and drive systematic performance improvement. By combining deep cost engineering expertise and industry-specific know-how with strong implementation capabilities, EFESO enables clients to deliver measurable results across the following areas:

- Reduction of material and process costs

- Increased operational efficiency at supplier sites

- Optimization of product specifications and design

- Improvement of indirect cost structures (SG&A)

- Long-term transparency and supplier partnerships

EFESO Success Model: Structured Building Blocks for Measurable Impact

With decades of experience and a proven methodology, EFESO supports clients across the full supplier management lifecycle — from selecting the right partners to unlocking cost and performance improvements, and ensuring lasting implementation.

A particular focus is on process optimization at the supplier level. We evaluate production and logistics operations, identify inefficiencies, and drive performance improvements. Key focus areas include material flows, setup times, capacity utilization, scrap rates, logistics, and quality. Using value stream analysis, we create transparency and define joint improvement actions with suppliers.

The result: a stronger year-over-year savings trajectory, more resilient value chains, and closer, more effective supplier partnerships.

Our approach follows a standardized, field-tested project model (see graphic). In the following modules, we identify weaknesses, develop optimization measures, and actively support their implementation.

1. Supplier Selection

2. Material Cost Reduction

We collect and analyze all procurement-relevant data, using tools like Linear Price Performance (LPP), Total Cost of Ownership (TCO), and Gap-to-BPG gap analysis. Additional methods include parametric costing and deep-dive cost structure breakdowns. We examine BOMs, purchase prices, material usage, and sourcing strategies to build strong negotiation arguments and technical cost-reduction levers.

3. Design & Specification Optimization

Using a fresh-eye approach and 360° analysis, we identify technical and commercial improvement opportunities to optimize design. Cost drivers often stem overengineered components, outdated specs, or non-standard designs. EFESO works with engineering, procurement, and technical teams to develop Design-to-Cost strategies that deliver measurable savings.

4. SG&A Optimization

We assess support functions like procurement, R&D, and administration, identifying inefficiencies through cross-functional benchmarking. This includes analysis of FTE distribution, role clarity, and process maturity. The goal is to streamline structures, improve efficiency, and leverage automation and digitalization for cost reduction.

5. Action Tracking & Implementation

All identified measures are reviewed and approved by a release steering committee, then moved into execution. A dedicated Project Management Office (PMO) ensures rigorous tracking, progress reporting, and effectiveness reviews. No measure is dropped without mutual agreement — ensuring consistent follow-through and impact realization.

EFESO TIGER-TEAM: Effective Task Force Management

Before or after SOP (Start of Production), certain situations, such as launch issues or impending supply disruptions, require urgent action to deliver concrete improvements and solutions quickly.

In these cases, speed and clarity are critical. We assemble fast-acting task force teams, the so-called TIGER-Teams, who work on-site with a clear structure and empower your organization to respond rapidly. Together, we define roles and responsibilities within the TIGER-Team. Alongside project managers on the company and supplier side, the team includes project leads from procurement, production, and quality management.

To properly assess the situation, adjust course, and ultimately achieve project goals, our TIGER-Teams typically follow a proven three-phase approach:

Maturity Assessment

At project kick-off, the team performs a “maturity check” of all suppliers to quickly establish a clear view of critical baseline factors: launch status, supply plans, and product/component quality. At the same time, suppliers are made aware of the critical situation.

Stabilization

The team focuses on resolving acute issues and mitigating supply risks, stabilizing operations, and transitioning from crisis mode to normal operations.

Safeguarding SOP

For upcoming SOPs, TIGER-Teams implement continuous monitoring and reporting, supporting operational teams with structured actions to ensure stable supply, process efficiency, and high-quality outputs.

Intervention During Series Production

After SOP, the TIGER-Team works to optimize existing supply processes and strategies. Focus areas include sustainable cost reduction, securing supply chains, and reviewing (and renegotiating, if necessary) existing supplier contracts. We also help resolve acute supply issues to ensure stable and cost-effective material availability for ongoing production.

Our solution portfolio for purchasing organizations