We consolidate all relevant data – spend, contract terms, Incoterms, forecasts, quality and delivery risks – into a single data cube.

Simultaneously, we define concrete target corridors with sponsors and stakeholders, such as ≥ 8% cost reduction, ≤ 2% risk exposure, or > 90% site coverage. The result: a clear project charter against which we can measure progress and success.

Functional & Category Strategy

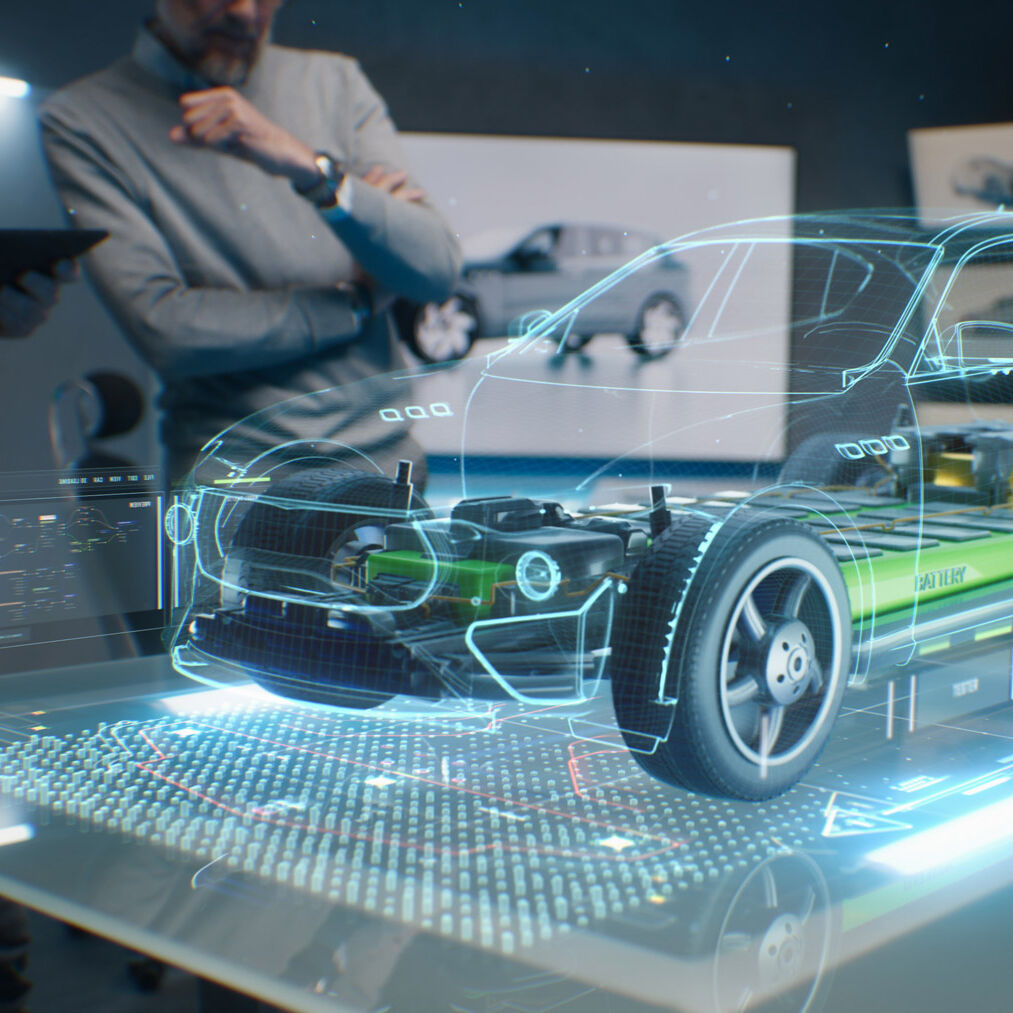

in automotive, industrial,

off-highway & more

in savings achieved

category projects

cost reduction per category*

In today’s volatile global environment — shaped by ESG demands and rapid technological change — many industrial companies face a critical challenge in their procurement functions. Despite increasing purchasing volumes, there is often no clear, forward-looking roadmap tailored to each category or part family. This strategic gap frequently leads to inconsistent pricing, overlapping specifications, and missed opportunities for innovation within supplier networks — all of which undermine daily operations. At the same time, procurement’s full potential remains underutilized, particularly regarding the significant opportunities categories offer for cost reduction, quality enhancement, and innovation acceleration.

Typical indicators signaling an urgent need for action include:

- Lack of spend transparency and fragmented stakeholder focus, with no comprehensive mapping of costs, risks, and value drivers.

- Inconsistent specifications hinder synergy effects across business units and/or locations.

- Unclear make-or-buy boundaries amid fluctuating capacity and utilization.

- Over-segmentation of categories and insufficient modularization, which prevents scalability and efficiency gains.

- Untapped or underutilized potential for innovation partnerships.

- Absence of technology roadmaps, limiting procurement’s contribution to future competitiveness.

Given that materials and purchased parts typically account for 60–80% of manufacturing costs, a targeted, integrated category and part family strategy is essential to maintaining market competitiveness. Such a strategy must align cost, risk, and innovation levers while enabling procurement teams to achieve meaningful cost savings and operational efficiencies.

Strategically Develop Product and Category Groups. Unlock Synergies. Minimize Risks.

The impact of a well-crafted category and part family strategy is demonstrated by proven results from EFESO projects where such strategies were successfully developed and implemented:

- 11% reduction in part costs through platform modules and dual sourcing at a Tier-1 automotive supplier.

- 18% complexity reduction in electrical components and a 25% faster time-to-market at an automotive OEM.

- 9% savings enabled by a global PCP* category strategy and harmonized specifications at a high-tech manufacturer.

*PCP = Purchasing-Costing-Product

EFESO Value Promise: Tangible Results and Reduced Risks

Leverage EFESO’s unique end-to-end approach to establish effective category and part family management within your procurement organization. Together, we systematically segment categories, thoughtfully define part families, and anchor concrete implementation roadmaps. Staying true to our mission – Real Results, Together – we commit to clear, result-driven targets alongside you:

- 15% reduction in material costs through bundling and standardization.

- 30% lower complexity in bills of materials and supplier portfolios.

- +20% increase in innovation rate with key suppliers.

- Proven reduction of supply risk through dual and multi-sourcing strategies.

- Sustainable steering via category dashboards and KPI-driven review cycles.

We combine market, technology, and value engineering expertise with pragmatic execution skills – collaborative, data-driven, and precisely targeted.

We combine market, technology, and value engineering expertise with pragmatic execution skills – collaborative, data-driven, and precisely targeted.

EFESO Success Model: Structured Building Blocks for Impact

Our approach is based on a standardized project model that has proven successful at numerous industrial companies and continues to deliver measurable results. We bring together nine structured building blocks that combine critical elements such as analysis, strategy formulation, and implementation within a clear, actionable workflow. This ensures that potential improvements are quickly identified, prioritized, and – through clean governance and a dedicated Project Management Office (PMO) – sustainably realized.

1. Baseline & Scoping

2. Strategic Alignment & Guardrails

Each category strategy must align with the overarching corporate strategy. We align company, product, technology, and sustainability strategies with procurement: Where are the differentiators? What are the make-or-buy boundaries? From this, we derive guardrails – binding guidelines to safeguard future decisions. Example: “No single supplier dependencies above 40% volume.”

3. Commodity & Spend Segmentation

We cluster total spend into homogeneous groups by technology, function, complexity, lifecycle, and value contribution, or benchmark existing clusters. Using analytical tools, we identify bundling and standardization potential. The segmentation delivers a heatmap highlighting the greatest levers for cost, risk, or innovation – setting clear priorities for subsequent steps.

4. Commodity Profiles & Commodity Portfolio

For each category, we create a detailed profile: spend, should-cost, total cost of ownership (transport, storage, customs), plus geo-, raw material, and credit risks. We enrich this with market data on capacity, consolidation, and tech trends. These profiles are consolidated into a portfolio matrix mapping each category by economic leverage vs. risk/complexity.

This immediately reveals leverage, strategic, bottleneck, or routine categories, allowing resources and measures to be focused effectively. Only then do we move into concrete levers.

5. Supply Market Analysis & Supplier Strategy Derivation

We analyze capacities, price indices, and technology and country risks to identify opportunities and bottlenecks. From this, we derive the supplier strategy: each supplier is classified as core partner, dual source, development partner, or phase-out candidate – complete with business cases (savings, investment, payback, CO₂ impact) and clear accountability. This makes value levers and areas for correction immediately visible.

6. Category & Supplier Portfolio

We integrate category and supplier perspectives into a multi-dimensional portfolio: value (spend, strategic importance), risk (monopoly, location, financials), innovation, and bargaining power. Each field is given a clear role, such as “Strategic Core,” “Leverage,” or “Bottleneck.” From this, we define focus areas (consolidation, dual sourcing, partnership, exit) and identify where investment in innovation or resilience is needed.

7. Strategy Development & Prioritisation

Based on these portfolios, we define target visions for each category: cost and price pathways, innovation roadmaps, and risk objectives for the next three to five years. We then evaluate all available levers (cost, risk, innovation) by impact vs. implementation effort and prioritize them in a concrete action roadmap, with a focus on quick wins.

8. Implementation Roadmap & PMO / Saving Potential Evaluation

All business cases undergo a savings potential evaluation: we quantify savings, investments, and payback, then prioritize measures accordingly. These are integrated into a roadmap with timelines, resource requirements, risks, and mitigation plans. A central PMO tracks progress, savings realization, and escalates as needed via real-time dashboards. Stage-gate reviews, lessons-learned loops, and automated savings tracking ensure sustained, measurable results that flow directly into P&L.

9. Cross-Functional Enablement & Governance

We build a dedicated team from procurement, cost engineering, R&D, operations, finance, and quality, and define RACI matrices, KPI dashboards, and review cycles. A supporting change plan and stakeholder communications ensure that new processes are accepted and actively applied across teams.

Our solution portfolio for purchasing organizations