Based on a structured and standardized data collection of the company-wide spend cube (which can be systematically structured in advance if needed), we conduct an AI-based analysis of the entire procurement portfolio. We use two best-in-class AI-powered analytics tools to identify concrete cost optimization measures and prepare them for supplier negotiations.

Potential levers include raw material price, energy cost, and currency analyses, as well as the identification of localization or dual sourcing potential and the evaluation of various LPP or NLPP models.

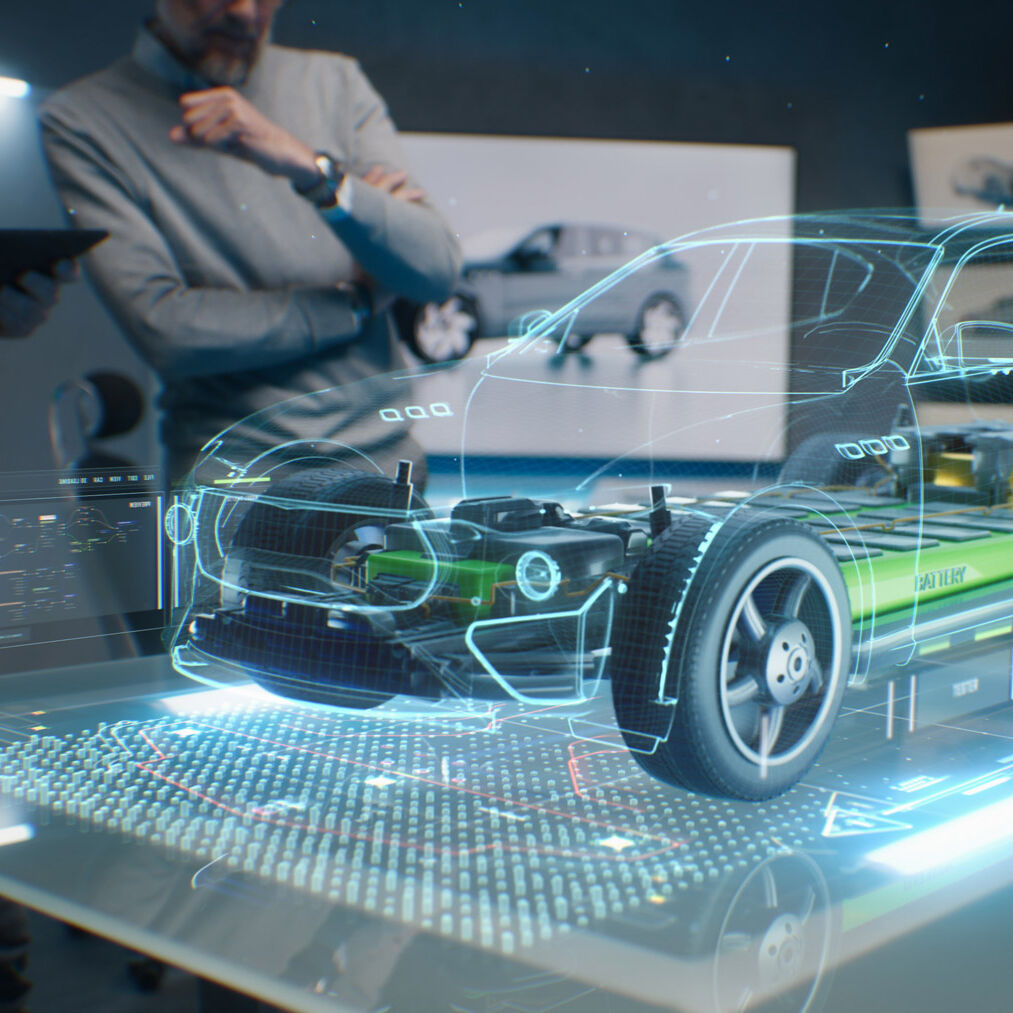

Material Costs Optimization

in automotive, industrial,

off-highway & more

in savings delivered

reduction

through commercial material cost programs*

through integrated benchmarking and holistic initiatives*

Industrial companies in high-cost countries – especially in Europe – are facing increasing challenges:

- Global supply chains are under growing pressure due to regional and climate-related crises;

- Trade instability due to escalating U.S. tariff policies;

- Market flooding by Chinese and other low-cost providers offering at below-market prices;

- Growing local pressures from labor costs, energy prices, and bureaucracy are threatening competitiveness.

In this environment, companies should look beyond their internal value chains for improvement potential. Material cost optimization is a highly effective lever for gaining stability and decision-making confidence – even in volatile markets.

Reduce material costs. Increase profitability. Shape the future.

In discrete manufacturing, material costs typically represent 40–60% (or more) of total product costs—making them the single largest cost driver. Optimizing material costs delivers high impact: a 5% cost reduction can boost profitability by up to 70%.

The EFESO Success Model: Three Key Dimensions of Material Cost Optimization

EFESO enables organizations to achieve strong, sustainable profitability gains with a holistic and field-proven approach. Our success is built on three key pillars:

Technology and Market Know-how

With 40+ years of experience, EFESO developed the “Best Practice Cost-Out Methodology” for the automotive and off-highway sectors. We’ve analyzed and optimized nearly 100% of the content of a modern vehicle (both combustion and electric), numerous off-highway applications, and a wide array of industrial products.

Expertise in End-to-End (E2E) Material Cost Program Execution

Our consultants apply their deep expertise in procurement and sourcing within a proven success framework. We have supported – and continue to support – clients across various industries in achieving their profitability goals. Choosing the right approach and method for each material cost program is key to maximizing results. Our experience in executing large-scale cost reduction programs across sectors has enabled us to generate substantial savings for our clients.

Execution Excellence

EFESO stands not only for strategic concepts and white papers – but for strong, hands-on implementation. Our tools and methods are field-tested, and our results speak for themselves: In recent months alone, we have delivered over €6 billion in sustainable savings for our clients.

EFESO Methodology: Two Workstreams with Up to Eight Performance Elements

Our methodology combines commercial and technical levers under structured project governance. A consistent execution rhythm, along with real-time tracking and reporting, ensures visibility into all actions and outcomes—accessible anytime, with just one click.

Technical Workstream

For complex technical components, modules, or systems, it can be highly effective to combine commercial cost optimization measures with technical levers. This not only significantly increases the savings potential but also ensures long-term impact. Typically, technical improvements generate mid- to long-term benefits – helping to further improve profitability even beyond the duration of the project.

Commercial Workstream

The commercial workstream ensures short-term payback of project costs. The goal is to achieve sustainable price reductions through supplier negotiations by identifying a range of concrete negotiation levers. This includes the full spectrum of available options – from tactical adjustments to identifying and qualifying new suppliers, and, if necessary, executing a complete re-sourcing process. EFESO's service elements in the commercial workstream are:

1. AI Spend Cube Analytics

2. Sourcing Portfolio Analysis and Prioritization

We segment the Product portfolio to identify commodities with the greatest savings potential. This prioritization ensures maximum impact with minimal resource use, focusing only on strategic or high-return categories.

3. AI Target Price Analysis / Should Costing

To further support supplier negotiations, representatives of prioritized commodities undergo target price analysis or should costing. Our experienced cost engineers use bottom-up calculations to determine the true greenfield cost level of the components.

The level of detail is aligned with market needs, ensuring efficient and credible negotiation support. We use cutting-edge AI-based costing tools to support the calculation process.

4. Global Competitive Sourcing and AI-Powered Supplier Search

In addition to fact-based and cost-driven arguments, competitive alternatives are often essential for successful negotiations. To create such alternatives, we initiate, structure, and manage a systematic global competitive sourcing process – aiming to bring multiple competitive suppliers into the negotiation for each procurement scope.

This systematically increases pressure on incumbent suppliers in future negotiations.

If no, too few, or only non-competitive suppliers exist in the current supplier portfolio, we also support a systematic and AI-based supplier search.

5. Competitive Sourcing & Supplier Negotiations

After all preceding analyses and methods have been used to identify and prepare specific negotiation levers, this step focuses entirely on execution. Our Competitive Sourcing & Negotiation Convention has proven to maximize project outcomes – by combining fact-based arguments, excellent negotiation preparation, and targeted competitive pressure. Clients benefit from a measurable and sustainable impact.

6. Technical Concept Battle

The EFESO Technical Concept Battle is designed to:

- Encourages early supplier involvement

- Prevents monopolistic sourcing

- Enhances supplier competitiveness

- Identifies the best cost-effective and low-carbon technical solutions

All suppliers participate under equal conditions, improving solution comparability and compliance.

7. Design-to-Cost / VA/VE

Our approach brings structure and accelerates the development of technical cost reduction measures. A key differentiator is our EFESO Fresh-Eye Approach, which, combined with integrated Should Costing expertise, enables a true outside-in perspective.

This allows our clients to benefit from independent idea generation by EFESO’s R&D experts. Cost optimization impacts are assessed more quickly, enabling immediate, cross-functional discussions in downstream Design-to-Cost (DtC) workshops with client teams – significantly accelerating the evaluation and implementation process.

Instead of merely collecting and re-packaging existing ideas from within the client's organization, we generate real added value. Selected suppliers can also be involved in the process, or entire cost optimization projects can be conducted jointly to tap into their innovation potential.

8. Concept and Supplier Cost-Down Workshops

Cost reduction opportunities often lie not only in the product or component design, but also within the supply chain. EFESO’s Supplier Cooperation Workshops provide a joint framework for making end-to-end supply chain costs transparent and closing gaps to best practice.

Relevant suppliers are actively involved and informed about the scope and objectives of the program.

Each workshop is tailored, actionable, and focused on measurable cost reductions. Workshops may be held in person or remotely and include joint negotiation and implementation planning.

Our solution portfolio for purchasing organizations