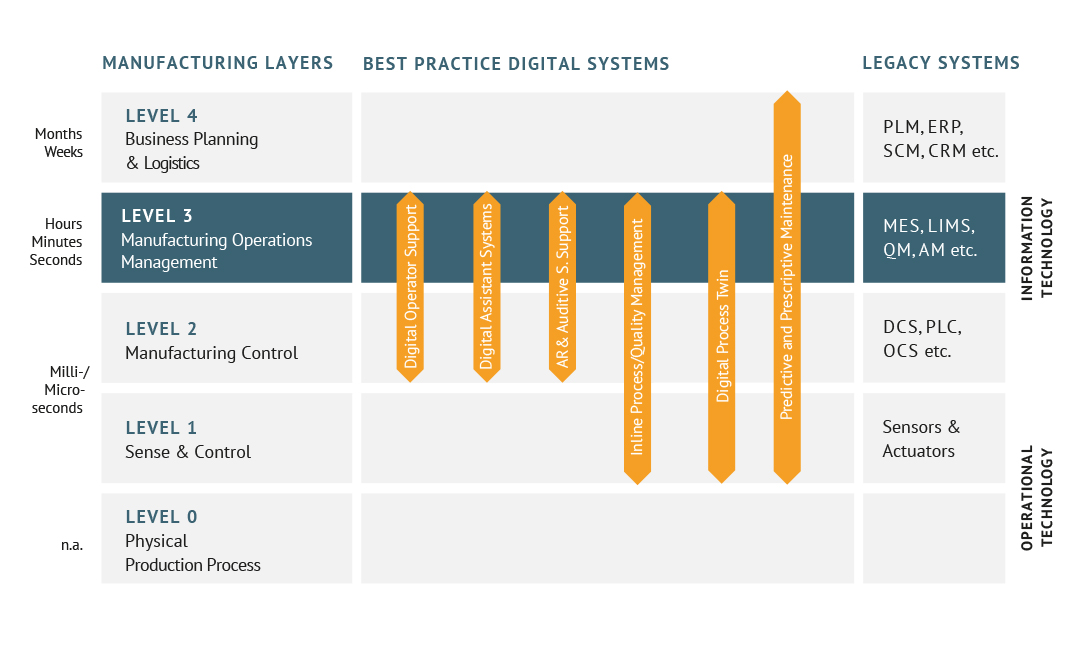

Best Practices

For highly specialized companies in the mechanical engineering sector, breaking into the digital product and service business does not usually lead directly through radical business model innovation or open joint platforms, but through product-related services and complementary digital solutions. They expand the core functions of their machines with additional digital services, thereby enabling radical leaps in efficiency. The spectrum ranges from hardware-supported solutions to purely software-based services. Digital hardware, software and service solutions are usually characterized by a common „anatomy“. They ...

... extend the capabilities of physical products by taking advantage of undefined digital technology impulses, such as deep learning, cognitive systems or innovative microsystems technologies;

... are based on the provision, analysis and interpretation of real-time operating, status and environment data for the machine;

... support intelligent decision making through descriptive, predictive or suggestive analyses at the machine or process level or are directly embedded in autonomous, independently deciding systems;

... contribute to the hyper-efficiency of modern systems and machinery through a higher degree of automation, quality improvements and shorter downtimes.

Digital Operator Support

Best Practice: Robert Bosch GmbH

Digital operators assist plant operators network the data of the machines used with the manufacturer’s knowledge databases and remote maintenance service. This way, incoming incidents are immediately categorised and solutions are proposed via an app, which system operators can implement independently or, in more complex cases, together with customer service via remote maintenance. This can reduce downtime and maintenance costs, and increase overall equipment efficiency (OEE).

Digital Assistant System

Best Practices: Airbus, Robert Bosch GmbH, Amazon

Digital assistant systems enable unskilled workers to complete complex manual processes in rapid succession as well as the full documentation of completed activities in real time. They are thus the precursor to automation and are used where no tactile, sensitive or cognitive robotics skills are available today. This enables personnel and quality control costs to be reduced as well as working cycles to be increased.

Augmented Reality Service Support

Best Practices: Palfinger AG, ABB, Körber AG

AR applications and auditory wearables support the independent execution of system maintenance and repairs by the operator. As part of the Augmented Reality service support, individual machines and possible incidents are independently identified, visual and auditory work instructions are given, maintenance and repair processes are automatically documented as well as support/mentoring being provided. This reduces maintenance times, repair times and downtimes, reduces personnel costs and ensures improved employee safety. AR is also used in the simulation of plants or machines, as well as in the training of operating personnel.

Predictive & Prescriptive Maintenance

Best Practices: Thyssenkrupp Aufzüge, GEA, Kapco Global, Aerospace Distribution

Predictive Analytics describes the predictive detection of potential incidents based on status and environment data. Machine-learning algorithms are used, which automatically identify critical data patterns on the basis of previously identified problems. In the framework of prescriptive maintenance, the machine independently provides recommendations for action and suggestions on how to prevent a predicted event. Downtimes, maintenance and spare parts costs can be reduced with simultaneous increases in uptimes and turnover.

In-line Process/Quality Management

Best Practice: Rhenus Lubs

In-line process or quality management optimises process parameters, taking into account the prevailing influencing factors in the respective process, thus enabling the generation of a precisely defined product. As a result, manufacturing processes can be reproduced in detail, throughput times can be reduced and quality control costs can be minimised.

Digital Process Twin

Best Practices: Klingelnberg GmbH, Bilsing Automation GmbH, Biohort GmbH

The digital image of a real physical manufacturing process describes the characteristics and properties of a component along the entire process chain. Thus, its characteristics and properties can be defined for each step along the process chain and corrective action taken if there is a deviation. The same applies to tool installation. This can reduce quality control costs and throughput times and production investments can be validated more effectively.