TOPICS & NEWS

Articles and interviews on current trends, technology and industry challenges, information on our consulting services, seminars and events as well as company topics:

Here you can find out what drives EFESO.

Newsletter #2/2022 – WELCOME TO THE INDUSTRY 4.0 AVANTGARDE

For almost a decade, the winners of the INDUSTRIE 4.0 AWARD have been showing how to set new standards in digitalization, automation and sustainability.

Do you know an award-worthy solution from practice? Then enter the race for this year's award! In this issue of the newsletter, we present the solutions we are looking for and what constitutes the Industrie 4.0 avantgarde:

- INDUSTRIE 4.0 AWARD 2022: Take part and win!

- Video: Efficient and sustainable vacuum cleaner production at B/S/H

- Best practice: Silent guardian for SPIE's energy supply

- Video: With flexible production lines to batch size 1 at Busch-Jaeger

INDUSTRIE 4.0 AWARD 2022: Take part and win!

Since 2013, EFESO has presented the INDUSTRIE 4.0 AWARD to companies that implement forward-looking Industry 4.0 solutions. Whether area-wide or as a proof of concept, whether in an SME or as a global player, whether automation or sustainability is the focus - whoever sets new standards is qualified to participate in the competition.

You can find out more about the application process, the jury of top-class industry decision-makers and the group of award winners on our website.

Efficient and sustainable vacuum cleaner production at B/S/H/

In its energy management, the B/S/H/ Hausgeräte GmbH plant in Bad Neustadt combines sustainability and cost reduction in an exemplary manner. From ordering raw materials to booking the completion of a vacuum cleaner, the plant automated many processes and networked its machines, transport and products for this purpose.

In the video, the winner of the INDUSTRIE 4.0 AWARD 2021 explains his approach and results of the winning project.

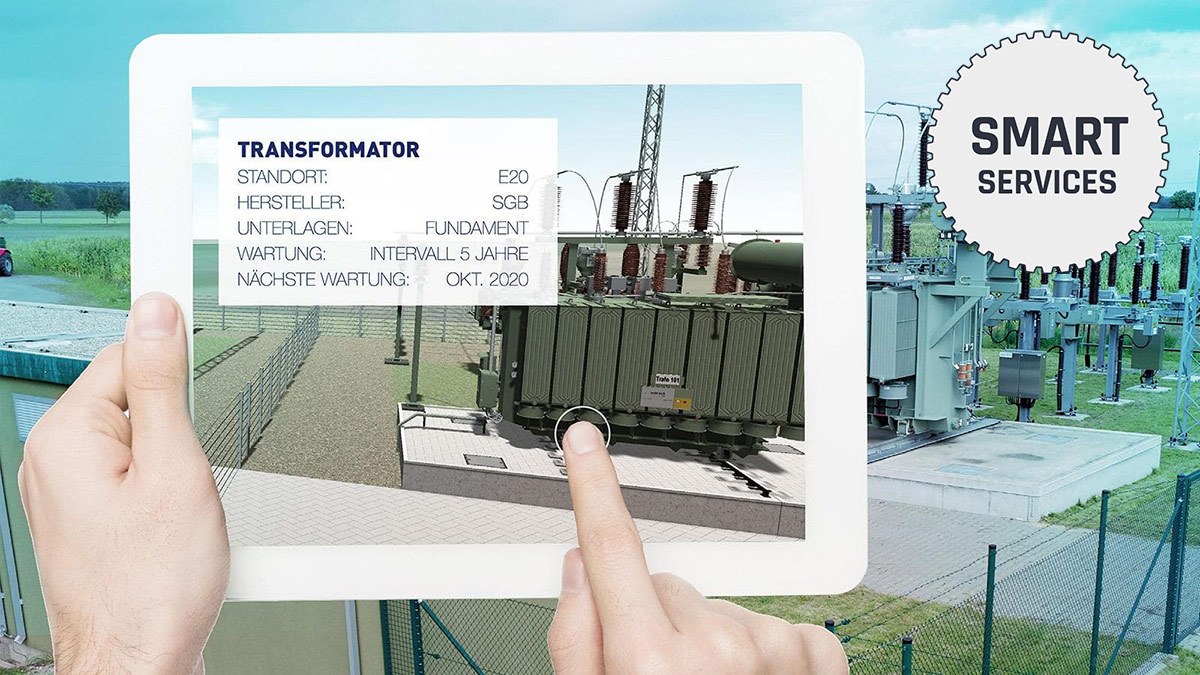

Silent guardian for the energy supply

With its Industry 4.0 solution "E.SPECTOR", SPIE Germany & Central Europe networks older plants with systems that already have a high degree of IoT maturity.

Why the high-tech camera system, which won the INDUSTRIE 4.0 AWARD 2021, allows more efficient use of resources in maintenance and what advantages it offers in other application scenarios, is described in our winner portrait.

With flexible production lines to batch size 1 at Busch-Jaeger

Busch-Jaeger has mastered the transformation from anonymous warehouse manufacturer to manufacturer of customized KNX sensors with batch size 1 at the Lüdenscheid site thanks to its fully digitized supply chain.

Our video portrait of the INDUSTRIE 4.0 AWARD 2019 winner shows how the company created the conditions for a scalable digitization solution with a flexible data architecture.