TOPICS & NEWS

Articles and interviews on current trends, technology and industry challenges, information on our consulting services, seminars and events as well as company topics:

Here you can find out what drives EFESO.

Interview

"Those who create transparency drive transformation instead of being driven by it."

Experte: Dr. Michael Breitling, Expert Director, EFESO | 06/25/2025 | Teilen auf in

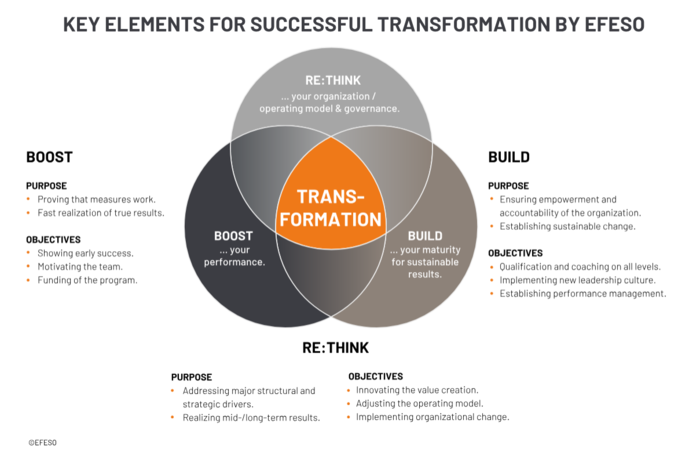

Why is one company able to achieve a turnaround in critical situations while another remains stuck? Dr. Michael Breitling, consultant at EFESO Management Consultants, explains key success factors—and how companies can continuously improve through the steps Boost, Re:think, and Build.

Dr. Breitling, when it comes to corporate transformation, we often hear the same buzzwords: courage, agility, or innovation. Yet in practice, many companies—with extensive transformation plans and reporting—end up in a kind of "accelerated standstill." Is transformation doomed to fail the moment it becomes institutionalized?

Dr. Michael Breitling (MB):Quite the opposite. A framework with realistic goals that are regularly challenged and adjusted is a key success factor for transformation processes. Embedding it as a fixed element in daily operations—clearly and transparently for all employees—makes perfect sense.

In most cases, stagnation and failure in organizational change stem from a lack of attention to initial conditions. After all, there is no one-size-fits-all blueprint for “transformation.” There are many different transformation scenarios. A plan is essential—but it must be grounded in a shared understanding within the organization of where the transformation journey is headed. Building that understanding—substantively, communicatively, and sustainably—is no simple task.

With the Transformation & Leadership team at EFESO, you initiate and support change projects across many industries and cultural environments worldwide. Are there common characteristics or recurring themes companies face in transformation processes?

MB: The more than 200 projects we've carried out worldwide over the past three years are all unique in their respective contexts. But there are some general patterns. Three aspects tend to recur—though with varying emphasis. First, change is usually driven by technical or operational needs—for example, increasing profitability, advancing digitalization, or realizing a “factory of the future.” Second, transformation involves systemic, structural changes to the organization: changes in organizational characteristics and, of course, the adaptation of processes, responsibilities, and tasks.

The third aspect is the organization's ability to initiate and sustain transformation independently over time. Ideally, this includes not just the technological and methodological dimensions—such as tools and professional training—but also the communicative dimension: Who from the leadership team sets clear goals and boundaries for the transformation? And who continues to drive it forward—independent of external consultants or coaches—from the shopfloor to the indirect functions? The answers to these questions gradually shape a company-specific understanding of what “transformation” means.

How do those at management level set reliable goals and “guard rails” for the transformation?

But how do you move from this rather abstract level to concrete annual, monthly, and weekly metrics that demonstrate: transformation isn't just happening somehow, it's moving in a defined direction? How do you make this concrete, understandable, and manageable?

MB: Through transparency—a simple answer, but hard to implement. Think of transparency as a coin: on one side, you see the KPIs reflecting the obstacles and progress within the (sub-)projects of your transformation journey. On the other side—independent but inseparably linked—you see the transformation’s progress as an ongoing improvement process.

Many companies focus on the KPIs and milestones during transformation. We often find that success or progress is measured on different levels and interpreted inconsistently. This means companies must first establish clarity about where they actually stand in terms of performance. These reference points then form the basis for technical improvements—whether it’s about lowering product costs and becoming profitable, optimizing operations and regaining competitiveness, or advancing digitalization to reduce dependence on skilled labor.

That’s the starting point—the core reason for the transformation. Just as important, however, is regularly reflecting on outcomes on the "other side of the coin": How many employees have been enabled to implement the changes? What are the individual results and remaining training needs? At a certain point, this reflection should be carried out from within the organization itself—with external experts acting as coaches rather than drivers of the transformation.

Let’s take it a step further: how should companies proceed in order to reliably determine whether they are on the right track and reaching their transformation goals?

MB: In general, you shouldn't use too many KPIs, otherwise you quickly lose sight of the forest for the trees. It's about defining the right KPIs for the context or process - and then cascading them. EBIT targets, for example, make no sense on the shopfloor. There, it is not the sales target that matters for employees, but whether they hit their shift production targets.

This means that the transformation KPIs must be broken down and cascaded across hierarchy levels. They must be visible and clearly understandable to everyone involved. For example, a worker should always know: Where am I right now? Is there still one more unit to be produced? Will I reach my production target? And what are the daily or weekly goals – are 200 or 250 units required?

This also means KPIs are meaningless without clear goals. If someone has a goal, they can ask: Did I reach it? If yes, check it off. If not—why not? That’s where a real discussion begins, and corrective actions can be identified. This puts employees directly into the continuous improvement process (CIP). This step is particularly important, as it also shifts the work culture. Whether it’s called CIP or something else doesn’t really matter—what matters is that every employee, regardless of their position, becomes part of the process. And it’s the responsibility of leadership to set the tone and lead by example.

Key figures are worthless if there are no clear objectives.

Let’s assume a company is already doing this well—how can it now drive transformation as an ongoing improvement process?

MB: If we continue thinking in terms of KPIs, this can be captured across three dimensions: people, topics, and measures. How many employees have I already reached in the transformation process—i.e., how many have been trained and qualified to apply continuous improvement at their workplace? How many are actively supporting the transformation with proactive improvement suggestions? And how many still need to be enabled—and in which (technical) areas?

This leads to transformation-specific KPIs that can be actively managed: How many improvement measures have been identified? What is their level of complexity, for instance? What savings have already been achieved as a result? And what does the pipeline of further measures look like—is it slowing down, or are there still enough ideas to implement? Anyone who can answer these questions has created the kind of transparency we mentioned earlier—the clarity of "Where do we stand?" And with that transparency, you're driving the transformation instead of being driven by it.

It is also essential to visualize the goals and results. Best practice companies work with dashboards where every employee can access relevant information relevant at any time. Typically, the data is linked and can be shared interactively between employees and teams, for example, to drill down into target achievement, employee qualifications, or transformation progress until, ideally, everything is truly understood. This again concerns both sides of the “coin”: Which workplace or plant is how far along in implementing its goals? And is the company “on track” in terms of the overall transformation project?

Practical Example "Transformation without limits"

BUILD, BOOST, RE:THINK – an automotive supplier realizes a new production system with OPEX orientation worldwide.

How do you succeed in launching and establishing this type of transformation in industrial companies?

MB: We define transformation as a triad composed of Boost, Re:think, and Build. When these three come together, their intersection becomes the transformation itself. How strongly each element comes into play depends on the specific task and the company's starting point.

Boost is the part that drives rapid performance improvements on a technical level. The focus here is on making successes visible and showing that change is real and effective. This motivates teams to go beyond what they’ve achieved proactively push further improvements—often uncovering savings that contribute to a kind of “self-financing” of the transformation. Depending on the manufacturing context, these savings can be significant, even early in the project.

Re:think, in contrast, focuses on structural, systemic changes that ensure the transformation is sustainable. It’s not enough to simply install a new IT system. In most cases, workflows or even responsibilities must be realigned—meaning they need to be changed or institutionalized accordingly.

And of course, transformation shouldn’t lose momentum.

MB: Exactly—that’s where the third element, Build, comes in. It’s about enabling employees, as already described, so they can actively shape and support change—both technically and emotionally. This, too, contributes to sustainability, acceptance, and ultimately the success of the transformation.

We understand transformation as a far-reaching, long-term change—one that remains flexible and adaptable along the way, but also introduces systemic and structural shifts to the very topics it addresses.

How does EFESO’s approach differ from other transformation methods?

MB: We deliver all three elements—Boost, Re:think, and Build—from a single source, and we do so globally. Even when it comes to highly industry-specific operational challenges, we don’t rely on external partners—we bring full in-house expertise. As an operations pure player, we are deeply familiar with our clients’ individual needs along their entire value chain—from the shopfloor to the management board.

We’ve also been addressing the dimension of organization, structure, and systemic change in all its forms for many years. Through the EFESO Academy and our in-house Human Dynamics experts, we help companies sharpen the transformation and continuous improvement mindset across the workforce—and positively influence it. In short: we know how transformation succeeds—when you work with the organization, not against it.

|

|

Thank you for Signing Up |