Digital Process Twins in Manufacturing

Digital Process Twins enable Holostic Production Management

By Robert Benacka, Member of the Management Board, ROI Management Consulting a.s.

1 Initial point: a complete mapping of the value stream as Digital Twin

2 How to build a Digital Process Twin

3 Basic rules for the further development of the twin

A good 150 years ago, an interesting custom took root among the Yoruba people of West Africa: While the Yoruba had regarded twins as evil for centuries, their superstition now suddenly shifted and saw them in a positive light – a cult of twins emerged. This adoration found a special expression in the production of Ibeji, fi gures of twins carved in wood that serve as containers for the soul of deceased twins, because the Yoruba believe that the souls of twins remain connected beyond death. If one twin dies, it must be fed, bathed and talked to like a living family member in order to ensure the survival of the other twin. In a certain way, this idea of interdependence between the real and symbolic worlds also infl uences the way we regard “digital twins” today. Of course, a digital twin in our factories no longer involves superstition. Instead, it is a digital copy of a concrete, physical object or product – for example a turbine, whose operational parameters are measured and represented virtually in order to allow predictions to be made concerning possible changes in performance or material characteristics. This may open up very exciting perspectives for the further development of products in terms of cyber-physical networking in Industry 4.0, but, as with the Ibeji of the Yoruba, it generally only focuses on the interaction of one pair of twins.

However, the digital twin approach offers significantly greater potential. What can be achieved when the entire value stream with all its processes is represented by a digital twin, i.e. a “digital process twin”? It would, for example, prevent quality problems in the manufacturing process before they arise, avoid downtimes, and predictively simulate new customer requirements.

3 Aspects are particularly important for this further development of the digital twin approach:

- a holistic understanding of the value stream and processes

- a more effective deployment of existing technological infrastructures

- data-based forecasting of events in the value stream and processes

A changed view of the value stream

New technologies on their own do not make a digital process twin. The way the value stream and value stream management are understood must change as well. In the past, production managers have concentrated on one question in this respect: How do I configure the value stream to make it more effective? The question is correct, but it only provided limited influence on the quality and OEE (overall equipment effectiveness) of the process. In order to improve these as well, quality and OEE results should be aligned with other information from production IT systems and thus be viewed holistically. This, however, is exactly what is not done in most production systems. On the contrary. A production planning and control (PPC) system has its “own view” of the manufacturing process, along with the machinery control units, the workstation operators, etc. Furthermore, many production lines are complex systems, especially in the automotive supply industry: The production process is subject to dynamic change over time, machines are not configured optimally, and fluctuation and differing levels of qualification among the production team are not uncommon. All this places a strain on production, and at the same time, there are generally no personnel capacities available to solve problems systematically. Quality assurance falls short in this instance, as it identifies and removes the symptoms of process errors but not the causes.

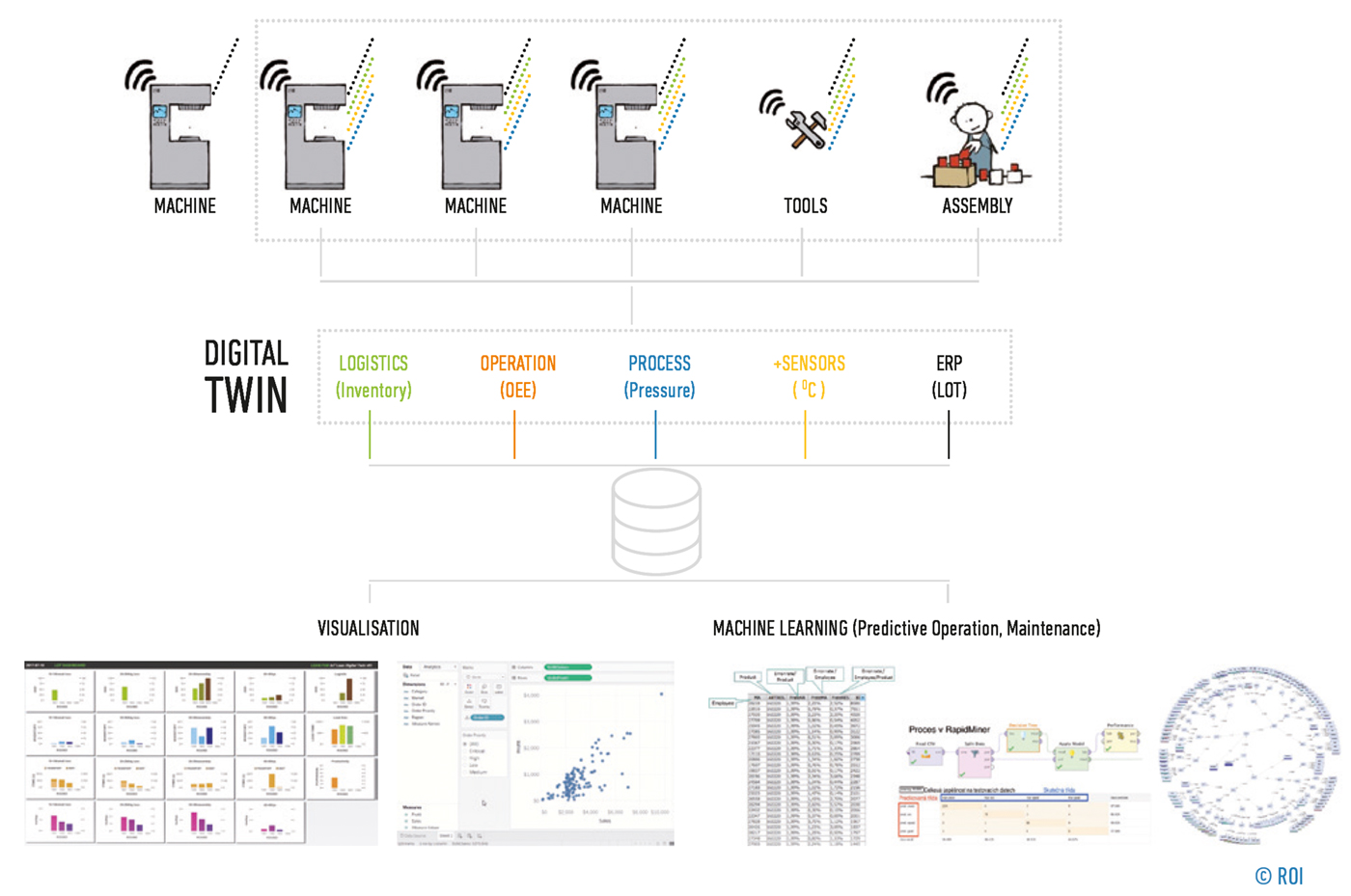

A digital process twin aims to resolve these problems: It collects and visualizes information that is relevant prior to, during and between the manufacturing steps (see diagram). This is valuable in two ways. Once a twin has been successfully developed, it can be adapted to other manufacturing systems. In addition, it reveals all the relevant correlations and thus makes the process more manageable. Two kinds of information output are important here. First, directly visible values such as lead time, and second, the history of machinery and process data that, thanks to digitalization, can be represented and analyzed. Directly visible values to be identified should include, for example, a wide range of KPIs concerning effectiveness, productivity, OEE, etc. However, a comprehensive evaluation of manufacturing processes needs to take into account that different value streams, e.g. for injection molding or die casting, also have different requirements and need different templates. For example, the temperature of the drier or tool for the production process may be relevant for injection molding, since a slight variation in the temperature or drying time can affect the quality. In contrast, other factors can be important in die casting or stamping.

Technologies and processes in harmony

The PPC or enterprise resource planning (ERP) systems supply essential information for a digital process twin, e.g. order numbers, production times, material consumption, and the assignment of staff to machines. How much material is used when and by which machine does not by any means adequately reveal sources of error or process obstacles. In addition, the (often manual) interim work steps often lead to waste and interruptions – this can very quickly cause losses running into thousands each day.

A larger number of relevant values will result in more correlations and hence greater insights

The following points should be taken into account when implementing a digital process twin, in order to reduce these costs:

- Existing PPC systems generally fail to adequately represent the manufacturing process. The following questions are helpful when developing a digital twin of the value stream: How were the implementation data qualifi ed? What important information is still not yet captured? Do the models that have been set up match actual production?

- Once implemented, many teams think that the PPC system automatically standardizes workfl ows. Here, it is important to examine whether the standards still meet current requirements for batches, cycle times and material usage. A twin should, for example, make any classical “black box” area transparent, e.g. details about workshop processing or reworking work items, or about what material was used on which machine. What programs were used to control it? Which employees are especially well suited for which tasks?

- Deconstructing production lines into many segments makes it more diffi cult to maintain an overview of the whole process. Although all the people involved are sometimes familiar with the problems that exist and the available solutions, change initiatives fail at departmental or business unit boundaries. Questions need to be asked in this case about where breaks in competence occur and how they can be overcome with the help of a digital process twin.

Receptiveness for new insights

However, the digital process twin of a value stream does not concentrate solely on representing correlations between machines or on human-machine interaction. It also considers tools and workplace equipment in order to detect additional potential sources of error. At the same time, it compares past and current information from the entire value chain. An important point here is that a larger number of relevant values will result in more correlations and hence greater insights. This creates the information basis for the “preventive” mode of the twin, i.e. predictive planning that, for example, assigns the right tool to employees, or which could use future shift or vacation schedules to show which employees with which qualifi cation need to be available for new customer orders, and possibly need to be trained accordingly in time – „could“ because the PPC systems in current production lines generally create work orders anonymously.

And yet even without this information, a digital process twin will allow a comprehensive picture of the production process beyond the existing production system relatively quickly. It is worthwhile being open for spontaneous ideas, new developments and extraordinary outcomes. Incidentally, there is also a special twist in the case of the Ibeji mentioned at the beginning of the article: The cult of the wooden fi gures may have contributed to the fact that, on average, every sixth birth among the Yoruba sees a delivery of twins – a peak value worldwide, as only one in 40 newborn children around the world is a twin. This is certainly not what the fi rst Ibeji artists planned.