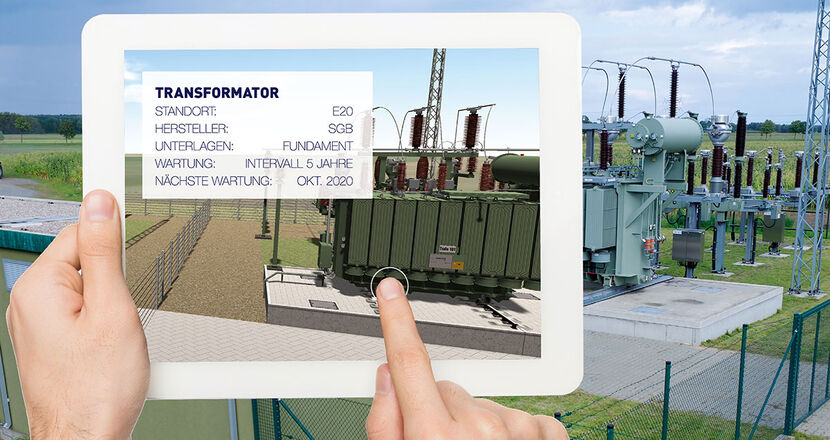

"The future of digital twins lies in cross-plant and cross-company deployment. "

Interview with Jonas van Thiel, Partner, EFESO

Articles and interviews on current trends, technology and industry challenges, information on our consulting services, seminars and events as well as company topics:

Here you can find out what drives EFESO.

Companies have a wide range of tools and methods at their disposal to help them use data profitably: whether the aim is to build IIoT architectures, embed automation processes, or to implement fundamental Industry 4.0 concepts.

In the market study "Best Consultants", the business magazine brand eins has been determining since 2014 which management consultancies are particularly convincing with competence, quality and professionalism in their projects.

One of the major challenges as we continue through the 21st century is to respond quickly and flexibly to customer requirements in the digital age. The EFESO Learning Campus helps to convey practical know-how and to strengthen competencies for the further development of processes, people and technologies in organisations.

Eight practical examples for the implementation of the Smart Factory.

How Artificial Intelligence and Gamification empower a global, agile Industry 4.0 supply chain.

Prof. Dr. Holger Bonin, Research Director of the IZA (Institute for the Study of Labor), on the consequences of automation, superstars of digital structural change and the limits of virtuality.

A high-tech camera system enables predictive maintenance.