(Kopie 1)

Bimodal Supply Chains

By Dr. Wolfgang Keplinger, ROI Management Consulting AG

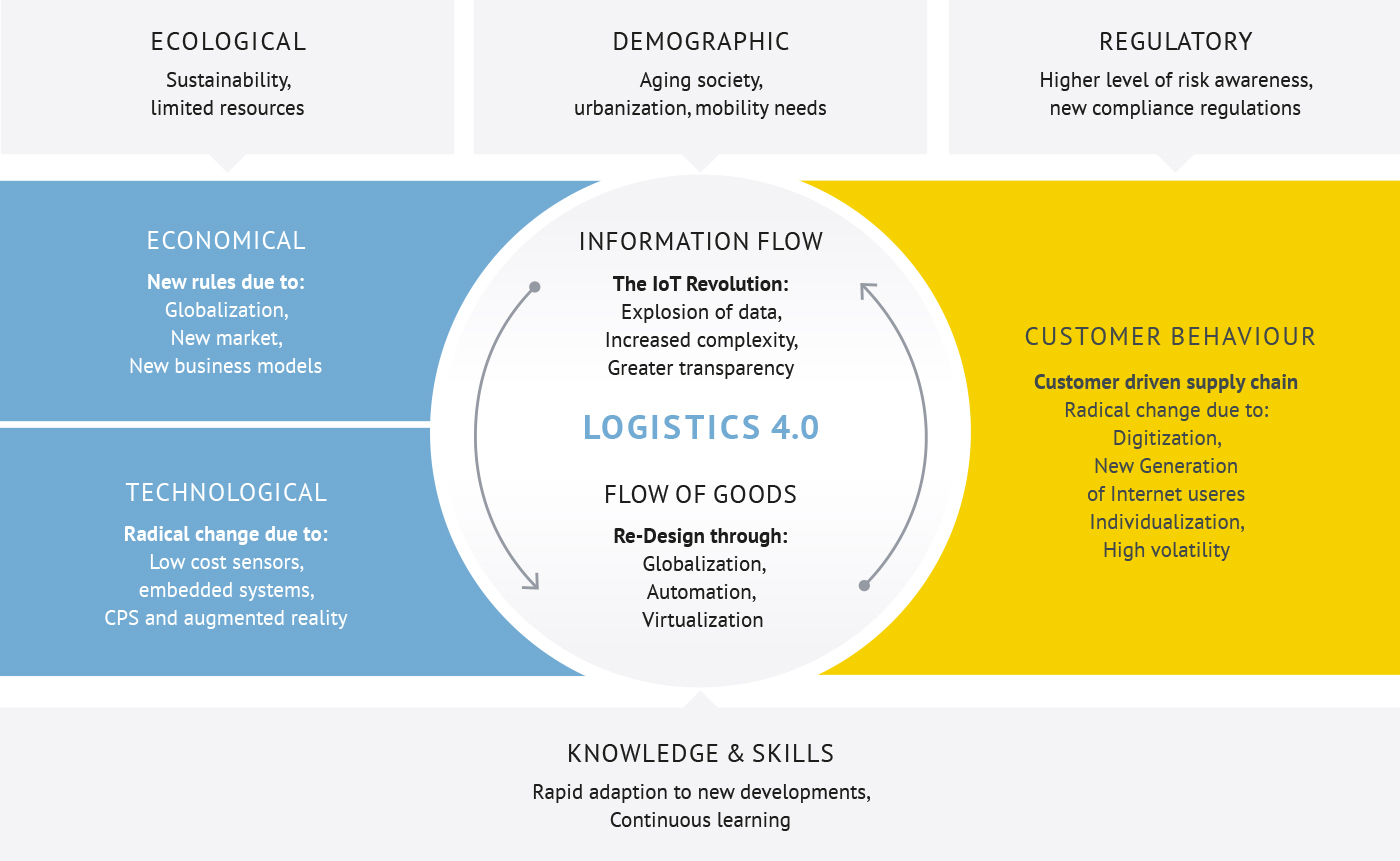

Logistik 4.0 is driven by a change in customer behaviour: A new generation of digital natives and smarter (grey) users sometimes operates continuously on the internet, sometimes even on multiple channels at the same time. A specific digital consumer behaviour has developed with them, which is characterized by the desire for individualized, short-term available products.

Logistics Superstars

This development has already spawned new or changed service providers: DHL mastered the turnaround from being a state-owned enterprise to becoming a competitive technology leader, and Amazon is (and has been) putting the customer at the centre of all considerations and creating a new logistics standard based on that model. And Zalando is proving to be the world champion of reverse logistics. One thing is common to all three examples: In all considerations and changes, they focus consistently on the customers and their expectations and align the logistics chain precisely to it.

Same Day Delivery Turns to Commodity

„Customer proximity“ is also produced by real-time data on buying behaviour and product usage. Product performance is no longer compared to performance specification, but to the actual expectations of the customer. Logistics top performers want to make it as easy as possible for their customers: Same-day delivery is turning into two-hour delivery; instead of pressing a button, the customer now orders by voice control through a chat bot. And the delivery to the front door is replaced by overnight delivery to the trunk of the locatable car or to another individual delivery point.

Growth Thanks to Bimodal Supply Chains

This intensive customer orientation in the supply chain has led to a serious paradigm shift in the value creation of logistics companies: „Functional silos“ from sales, development and operations are a thing of the past; in their place, logistics managers are taking advantage of integrated demand management, replenishment and production. This is the only way for providers of complex technological products, such as smart phones or tablets, to bring new technological solutions to market maturity every year in high-frequency innovation activities. Bimodal supply chains thus enable an excellent cost position within a supply chain. At the same time they support the desired growth through the rapid conquest of new technologies and markets. This simultaneous mastering of two different capabilities (continuous performance improvement and cost reduction on the one hand, and innovation and growth on the other) is what we call bimodal supply chain management.

Innovation Excellence as a New Supply Chain Requirement

The new component of this bimodal supply chain strategy is the rapid development and adaptation of innovations. Previously, logistics was primarily known to improve service and reduce costs. But the new top performers also impress with their operational as well as their innovation excellence. Companies cannot only learn from them how to use bimodal supply chains to create optimal customer relationships.

They can also follow the best practices of market leaders in order to

- quickly build up new suppliers;

- explore innovative paths with existing suppliers (co-innovation);

- work together with the development department to design and deliver new product generations in the shortest possible time;

- bring new talents on board with HR and to organize cross-functional collaboration within the company;

- work with IT to develop new software solutions;

- rapidly integrate new acquisitions with M&A.

This simultaneous mastering of two different capabilities is what we call bimodal supply chain management.

When the Package Finds the Recipient

This innovation perspective must not become a chore; instead it should be deeply rooted in the DNA of the company. After all, the customers, competitors and technological possibilities are guaranteed to always be one step ahead of the company’s planning. An example: Thinking more in-depth about the possibilities of smart analytics, soon, with the help of transaction data and calendar entries stored on smart phones, the expected shipment can be automatically directed to where we are most likely to be at the earliest possible arrival time of the shipment. The „logistic clockwork“ is therefore clearly ticking digitally - and faster and faster in terms of customer orientation.