BREAKING THE COMPLEXITY SOUND BARRIER

THE LIMITS OF SIMPLIFICATION

Lean Production is based on the principle of complexity reduction. However, in view of the increasing demands of modern manufacturing systems with regard to the speed, flexibility and variance demanded by customers, classic lean approaches are increasingly reaching their limits. A training simulation of ROI sensitizes employees to the consequences of increasing requirements in the manufacturing process and at the same time shows new ways for a digitally supported lean production approach.

A tractor manufacturer increases the number of its equipment variants multiple times in one fell swoop. The consequences in manufacturing are immediately noticeable: throughput times increase, the error rate in assembly increases and lean principles that have already been learned are abandoned. As a reaction, the company introduces digital systems, such as Sequenced Material Staging or Intelligent Routing, in assembly - with success: Productivity regains momentum, quality improves. The assembly line is stable despite a greater variety of variants.

What normally takes place within years or even decades takes place here in 2-3 hours. The described scenario is not a real assembly, but part of the ROI-Lean Digital-IoT-Simulation. There the participants experience what happens in many companies in time-lapse mostly creepingly: High customer-specific customization, ever shorter delivery times and more comprehensive product features ensure more complexity and higher control effort. Despite lean-optimized processes, error susceptibility and waste in the system are growing; the proportion of non-value-adding activities is increasing extremely. In short: classic lean approaches are reaching their limits - processes can no longer be controlled by humans.

This is exactly where the ROI simulation comes in and supports the transition from classic lean production to a lean digital approach. The assembly process of a tractor manufacturer is simulated using Lego components. In three rounds, up to eight participants take on various tasks, such as assembly activities, logistics and quality control, with the aim of producing as many tractors as possible without defects within a seven-minute shift. The framework conditions for the participants change from round to round in order to sensitize them to the increasing complexity of the assembly process and possible countermeasures:

ROUND 1: CLASSICALLY OPTIMIZED LEAN PRODUCTION WITH ONE VARIANT

In the first round of simulation, a single product variant of the tractor is manufactured on an assembly line optimized according to lean principles. The participants carry out standardized assembly processes at five assembly workstations. The required components are delivered just-in-sequence from the route train. The participants will experience how a synchronized assembly line, taking into account classic lean principles such as one-piece flow or kanban replenishment systems, enables high productivity and low error rates.

ROUND 2: LEAN PRODUCTION WITH GREATLY INCREASED COMPLEXITY (VIA VARIANCE)

In round two, the number of product variants is increased from one to over 10,000. This increases the complexity of the overall process: In addition to the previous roles, a participant takes over manufacturing control by compiling the parts lists that match the customer orders and integrating them into the assembly process. At the assembly workstations themselves, the complexity increases as the employees there are suddenly confronted with different assembly steps and new work instructions, which they first have to select. These additional work steps quickly lead to paralysis of the entire system. While 14 tractors could still be manufactured in the first round of the game, an average of two were produced in this round. The participants experience how the mostly creeping changes in the manufacturing system can have a massive impact on productivity and how classic lean principles can no longer work on their own in view of increasing complexity.

ROUND 3: LEAN PRODUCTION WITH GREATLY INCREASED COMPLEXITY AND SUPPORT FROM INDUSTRY 4.0 ELEMENTS

In round three, the assembly line is converted from analog to digital control. Instead of written work instructions, production orders and parts lists on paper, the individual assembly stations are equipped with tablets linked to a cloud-based product database. New orders are fed directly into this database via a product configurator. The corresponding order details are stored in an RFID tagged container. By scanning the container at each workstation, the assembly employees receive the appropriate work instructions and visualization on their tablet. In addition, only those parts are delivered just-in-time that are actually required for the respective work step. This and other industry 4.0 elements considerably reduce the search and inspection effort along the assembly line. The participants will thus experience how digitally networked technologies and assistance systems make the increased complexity in the assembly process manageable, ensure process stability and productivity and supplement lean production in a meaningful way.

MODULE 3: PILOTING AND PREPARATION ROLL OUT

THE END OF THE ETERNAL PILOT

The pilot phase is one of the most sensitive and critical phases of a Lean project. The aim here is to translate the assumptions from the planning phase into concrete measures and to test them in practice. Sensitive, above all, because the involvement of employees in lean activities requires intensive support and a great deal of sensitivity. Critical, because in this phase in particular there is a risk of a number of mistakes that could jeopardize the success of the entire project in the long term.

In the 1990s and 2000s, for example, companies preferred to use staff units and project teams to introduce lean in their departments as internal consultants. Despite the high level of expertise of the trainers and teams employed, many of the initiatives failed because the lean know-how and culture could not be sustainably anchored in the divisions. The knowledge also went with the consultants - the projects were forever stuck in the pilot phase.

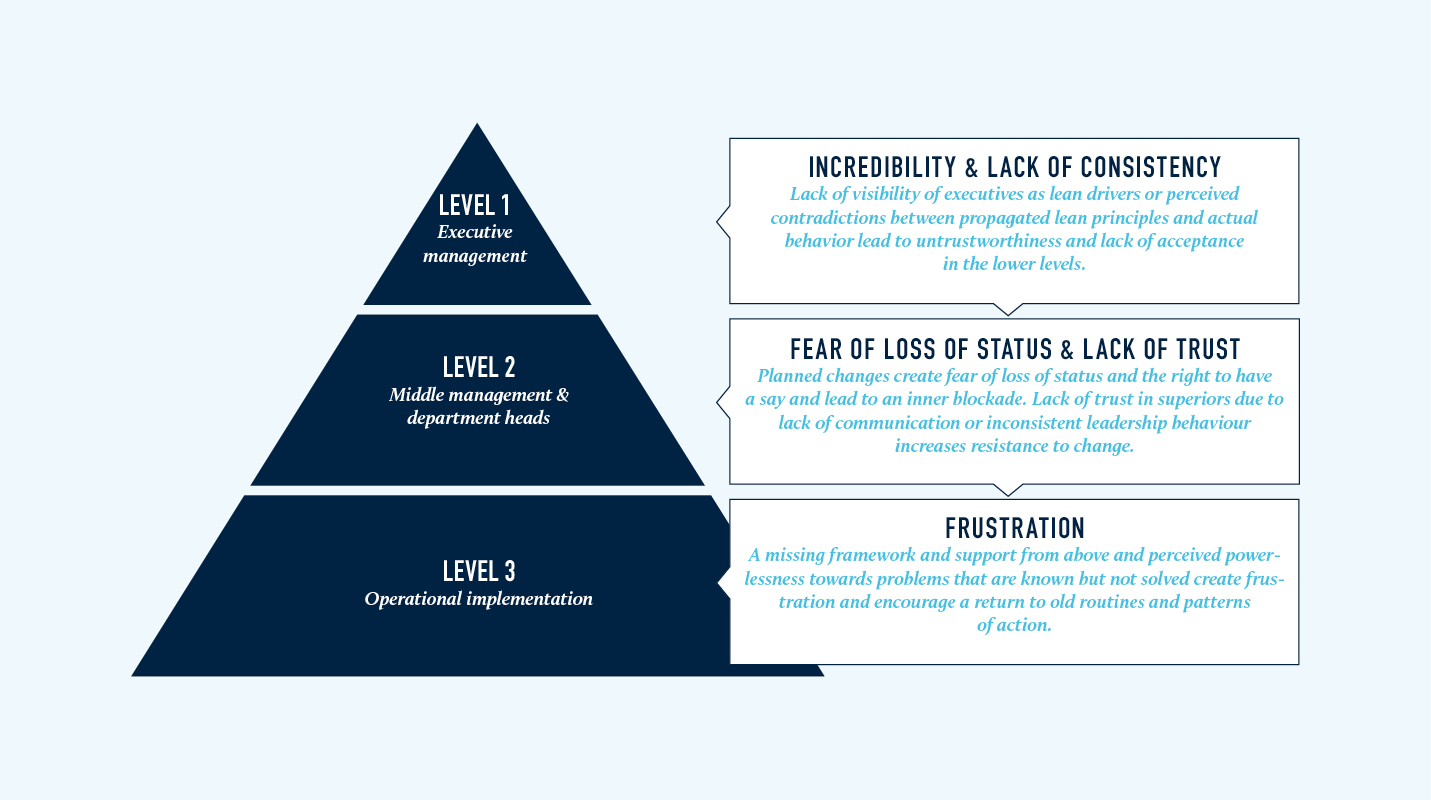

In order to counteract such undesirable developments already in the pilot phase, companies should closely involve the operative specialists and managers on the shop floor from the outset and sensitize them to the planned measures. The following success factors are important:

Making success visible

Lighthouse projects can help to make the lean changes visible at the shop floor level (e.g. through OEE improvement, workplace standards, inventory reduction) and thus sensitize employees to the planned lean measures. This requires a clear cause-and-effect relationship between the measures taken and the change achieved.

User-centered development

In order to prevent lean measures from being designed to ‘bypass’ the process or the user, close involvement of employees in the shop floor is crucial. User stories and key users help to adapt the tools used to the requirements of the employees or the process and are the touchstone for the meaningfulness of the planned measures at the same time.

Qualify for specific target groups

A central prerequisite for the successful implementation of the planned measures is the target group-specific qualification of employees across all organizational levels. Depending on the scope of the project, this includes both lean and digital methods. A decisive factor here is, on the one hand, target-oriented qualification geared to the needs of the respective employees and, on the other, practical relevance. By training lean experts and lead users, know-how is anchored in the respective areas for the long term.

Define rules

In addition to the qualification of employees, the appropriate management and control systems must also be provided in this phase, which enable continuous decision-making and problem-solving paths from management to the shop floor. This includes, for example, shop-floor management pilots (physical and digital) or the development of KPI systems, cascades of key figures and decentralised problem-solving competence.

Define roles and responsibilities

An effective leadership and management system requires managers at all levels to have a precise understanding of their own leadership role within the framework of the Lean Project. This includes, for example, actively requesting feedback as part of the goal development process, regularly reviewing the processes on site (Go Gemba) and ensuring an openly lived error culture in its area.

Accompanying and communicating change

For an effective anchoring of the lean concept in the organization, the introduction of lean projects must go hand in hand with systematic communication measures. A two-stage process is particularly promising, consisting of a cascade of short training sessions and information events that the operational managers themselves carry out and supplementary, centrally controlled communication measures that make the implementation successes visible and tangible.

Quick start

Lighthouse projects for streamlining processes and introducing lean concepts (process approach) are particularly suitable as starting points for large-scale lean projects: e.g. cycle optimization, flow concepts, pull control. They can be accompanied by digital pilots for the first application of smarter (IoT) technologies (system approach): e.g. predictive maintenance, digital Q-control loops, Smart Logistics, Smart Tooling, real time performance tracking. We recommend precise documentation of the implementation process and recording of lessons learned for use in the later roll-out plan (local to global).