LEAN’S LAST RACE?

No management approach has shaped manufacturing systems as much as lean management over the past thirty years. But although lean is now often regarded as a commodity, its true potential has hardly been tapped to date. New advances in technology, psychology and analytics will make the next thirty years even more exciting than the last.

When Usain Bolt crossed the finish line of the Beijing Olympic Stadium on the evening of August 16, 2008, he succeeded in doing something that shouldn’t have been possible. He had just covered the 100 meters in exactly 9.69 seconds. 0.03 seconds faster than it is physically possible for a human being according to the calculations of leading sports scientists. With his top run, he not only set a new world record, but also questioned the assumptions about the limits of human performance.

The question as to how far one can still advance the optimization of one’s own performance is also of concern to those responsible for production in industrial manufacturing. For decades, lean production was regarded as the dominant paradigm when it came to shortening throughput times, increasing machine availability or ensuring quality standards. By applying lean principles such as line balancing, pull principle

or one-piece flow, they tried to further exploit the efficiency of their manufacturing systems. But in the meantime, other issues have pushed the lean factory off the management agenda. And some believe that Lean has already reached the limits of its capabilities.

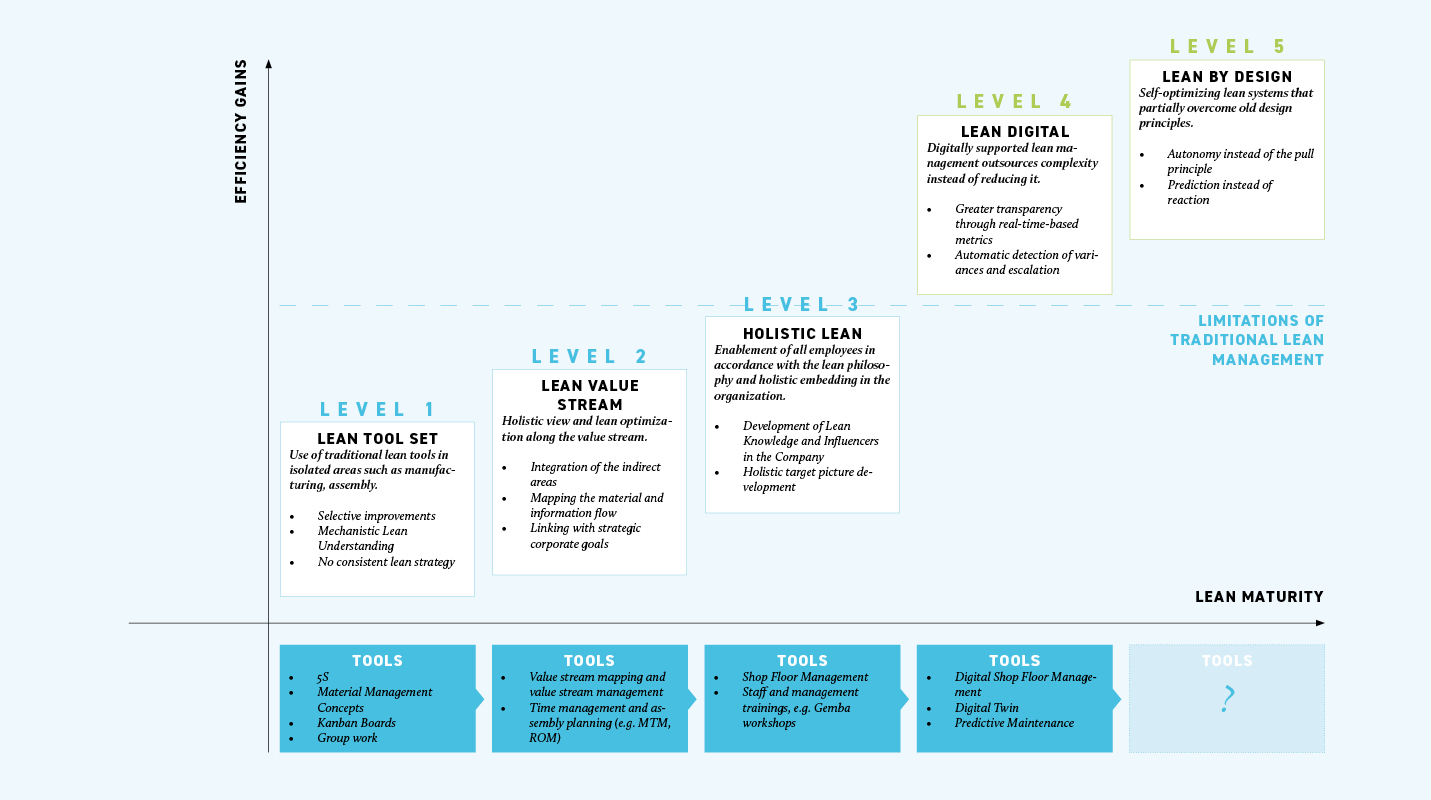

In fact, however, most companies are only just beginning their lean development. On the one hand, because they often do not yet implement and further develop existing approaches consistently enough. On the other hand, because the integration of new technologies into lean management enables completely new efficiency gains. Together, these two factors create potential that could double the level of productivity achieved to date. Or to put it another way: As if Usain Bolt was running the 100 meters in 4.8 seconds instead of 9.6 seconds. In order for Lean to reach these record levels, it has to go through several evolutionary stages:

9,6 SECONDS FROM TOOLBOX TO MANAGEMENT APPROACH

If you walk through the workshops of German companies today, the traces of Lean Manufacturing are omnipresent. Workplaces are designed according to the 5S principle, posters recall the design principles of lean production and shop floor boards document current events on site. The deeper view into the factories, however, shows a much more heterogeneous picture and still numerous deficits:

In theory, manufacturing systems are often very well described. In practice, however, the increases in efficiency achieved so far are mostly the result of isolated improvement projects and point kaizens that are located at the level of classic lean tools such as material control concepts, kanban or teamwork. This is usually due to a wrong understanding of lean as a toolbox that is used for the short-term realization of certain cost or quality goals.

The consequence: Lean initiatives often get stuck in the pilot phase or are not consistently further developed after the respective KPI target has been reached. At the same time, however, as the demands of the market continue to develop rapidly, for example in the direction of individualized products or shorter lead times, the effect of these unique and static lean initiatives usually fizzles out without having a lasting effect - especially since they are usually limited to individual lines or work areas such as assembly.

8 SECONDS FROM VALUE STREAM TO BUSINESS MODEL PERSPECTIVE

But added value doesn’t just begin in manufacturing. And above all, it does not end there. This applies all the more to smart products and components that are able to collect and communicate data throughout their entire lifecycle, from the manufacturing process through to use by the end customer. Lean must take this development into account. On the one hand, it also includes indirect areas such as logistics or maintenance in the value stream design. On the other hand, as value stream analyses are based not only on the material flow but also on the information flow and the IT systems used, in order to identify waste in information technology and to be able to switch it off later.

At the same time, this holistic approach must also be reflected in the target image. Instead of starting at the level of key figures, e.g. to reduce throughput times or downtimes, lean initiatives must ask where business processes are heading. Where are the challenges of the market? Do I need to get faster? Do I have to go one step higher in the direction of quality? Is delivery flexibility perhaps more important than productivity? Lean management automatically moves closer to the corporate and production strategy - away from Lean as a tool for KPI optimization and towards a strategic value driver.

7 SECONDS FROM TOP FLOOR TO SHOP FLOOR

The transformation of these overarching target images into concrete actions and behaviors at the point of value creation and their sustainable anchoring continues to be one of the greatest challenges in Lean Management. For the further you dive down the much-quoted “iceberg” towards “Lean Culture” and “Lean Thinking”, the more Lean a philosophy often becomes. In fact, however, there are very concrete measures that can help to permanently anchor a culture of continuous improvement in the company:

On the one hand, the systematic development of lean know-how in the shop floor: Instead of bundling knowledge in external staff positions or project teams, the training of key users and lean influencers at employee and master level was intended to permanently strengthen lean expertise on site. A decisive factor here is the targeted qualification of employees. Nobody needs to know 97 lean methods. Instead, trainings should be adapted to the actual qualification requirements and should take place at the real object or during ongoing operations. The right qualification of the middle and upper management level is just as central: only if Lean is understood as a management philosophy the managers can also take on the active driving role and ensure sustainability.

On the other hand, abstract objectives must be translated into concrete key figures and process parameters that are understandable and can actually be influenced by the shop floor employee. The basis for this is formed by cascades of key figures with which target/actual deviations can be recorded clearly and transparently at all company levels. At the same time, they make it possible to initiate problem-solving processes that clearly define a direction for improvement (but not the solution) and thus support employees in their daily improvement routine.

The central management instrument is the shop floor management. When implemented correctly, it not only secures and stabilizes the operative control of value-adding processes across all corporate hierarchies, but also promotes continuous process improvement while simultaneously developing employees and their problem-solving skills.

6 SECONDS FROM COMPLEXITY REDUCTION TO COMPLEXITY OUTSOURCING

At this point a caesura takes place. This is where the area of conventional optimizations ends, which can be achieved by exploiting and constantly developing the well-known lean principles. What now follows is the entry into a new phase of lean manufacturing, which is based on the same basic principles, but is making a decisive paradigm shift: Where Lean has so far attempted to reduce or control complexity by dividing complex systems and processes into simple, operationally more manageable units, digital technologies enable this complexity to be outsourced and kept away from the user.

As part of digital shop floor management, for example, sensor-supported real-time data and intelligent apps are replacing decentralised Excel solutions, manual lists and handwritten cards. At the same time, the provision of real-time data can significantly improve both the reaction speed and the error rate in the shop floor. Virtually all operations along the value stream can be digitally enhanced in this way: whether predictive maintenance solutions, real-time quality control loops, self-controlling logistics systems or human-machine collaboration in the context of workplace design. The combination of Industry 4.0 and Lean enables optimization potentials that are about as high as what has been realized in thirty years of conventional lean manufacturing. However, these effects only become effective if they are based on the principles of a lean process. Otherwise, digital technologies create new complexity instead of keeping it away from the user. Or as former Telefónica CEO Thorsten Dirks once put it: “If you digitize a shit process, you will have a shit digital process.”

At the end of this step-by-step lean evolution is the vision of a fully digitized, lean value stream that synchronizes all information and material flows directly or indirectly involved in value creation, from development to manufacturing to logistics, and makes the information contained therein usable. Approaches to this vision can already be seen today in digital process twinning.

Along this value stream, the individual process steps will increasingly shift in the direction of autonomous systems that not only recognize process deviations, but also independently find solutions, for example in the sense of prescriptive logic. And this is where it gets exciting. Because where processes increasingly control themselves, Lean must begin to re-evaluate certain basic principles. How meaningful is a pulling system in the age of predictive systems?

Against this backdrop, lean experts must remain open to new technologies on the one hand and free themselves from rigid rules and methods on the other. Instead, it is a matter of allowing experiments in the sense of the lean concept and thereby enabling new process optimizations. The starting point is always the customer benefit, which, thanks to smart products and product-related services, is moving ever closer to the development and manufacturing processes. One question for such an experiment could be, for example, how individual customer requirements can be realized without additional planning effort at the workstations. And this is where Lean leaves manufacturing and becomes a cross-company management approach.

THE RACE IS NOT OVER YET

Of course, Lean hasn’t come to the end with this. The fact that a system can no longer be optimized is impossible. So there will be new development stages and areas in the future in which Lean can advance thanks to new technologies. An end to the records is therefore not in sight.

Usain Bolt won´t care. He now gave up the race.

THE ROAD TO LEAN MANUFACTURING

THE PREREQUISITES FOR LEAN PROJECTS CAN BE EXTREMELY DIVERSE.

Depending on whether a company has been dealing with the topic for years or has completely neglected the further development of its manufacturing system due to rapid growth. Whether the measures concern individual series of a product or the global manufacturing network of a company. Whether the focus is on increasing flexibility and customer-specific manufacturing or on overall system effectiveness.

However, as different as the framework conditions are in detail, certain success factors usually apply, which can be transferred to all types of lean projects. In addition to a systematic definition of objectives in line with the corporate strategy, these include the targeted qualification of employees and managers as well as the implementation of measures and structures to permanently anchor the lean principles in the overall organization.

Based on these modules, the following sections describe current findings and examples of success for the introduction and global scaling of lean manufacturing.

MODULE 1: DIAGNOSIS, BENCHMARKING AND DETERMINATION OF POTENTIAL (CURRENT STATE)

Islands of efficiency

When the Lean Production approach came to Europe in the 90s, it was closely linked to the instrument of the “Point Kaizens”. The idea behind it was simple: Instead of carrying out a complex reconfiguration of the manufacturing system, the first step was to achieve rapid lean successes through isolated optimization measures in clearly defined areas, which then merged to form a complete system. However, the hoped-for effects largely failed to materialize. The optimized areas were successful on a small scale. Without a connection to the remaining value stream, however, these would fizzle out because, for example, upstream workstations did not work in the same cycle and thus caused downtimes at the downstream workstation. Islands of efficiency emerged - in a sea of waste.

The introduction of lean manufacturing based on point kaizens has therefore largely been replaced today by a more systematic approach that does not focus on working groups but on value stream or organizational levels. If this systematic approach is followed, a lean project begins with a comprehensive analysis of the existing manufacturing system. This comprises three central elements:

Determining the Lean Maturity Level

Standardized assessments and method scans are used to determine an organization’s degree of lean maturity. In addition to the classic process design and the methods used in manufacturing, this also evaluates the indirect areas such as purchasing, development, maintenance or shop floor management. In addition, the “Lean Capability”, i.e. the ability to make changes at the management level, for example with regard to attention, mindset, target systems and the quality of managers at the lower levels, is also examined. This provides an initial qualitative picture to answer the question: Where do we stand and how far are we from best practice?

Quantitative potential derivation

On the basis of this qualitative examination of the own systems, standardized calculation methods can then be used to derive the technical and business potential of possible lean measures. The latter in particular is crucial in order to generate the necessary attention for the measures at management level and to ensure the necessary support from the management level for the subsequent implementation stages.

External benchmarks

In addition to the internal determination of potential, external benchmarks also help to evaluate the economic potential of lean measures. They also provide important information on the selection and design of the tools used and save time in the design phase by adopting best practices.