ROI DIALOG Issue 62

SMART FACTORY 2020 – Intermediate stand on the way to the intelligent factory.

Articles and interviews on current trends, technology and industry challenges, information on our consulting services, seminars and events as well as company topics:

Here you can find out what drives EFESO.

SMART FACTORY 2020 – Intermediate stand on the way to the intelligent factory.

A medium-sized company rents out construction machinery and conveyor systems. In order to digitize equipment rental and make additional services possible, it relies on smart contracts – a blockchain use case.

Modern value-added processes are increasingly dependent on dynamic cooperation. Thomas Müller, CEO & Co-Founder of EVAN GmbH, describes how blockchain technology ensures trust there.

Orientation in times of uncertainty: Six certainties about the Blockchain technology by Dr. Markus Jostock, Founder & Managing Director of ARXUM.

Assumptions about the reception of blockchain technology and the consequences for adaptation. Interview with Dr. Martin Kiel, Codecentric AG/the black frame.

Blockchain technology has the potential to change established patterns in one fell swoop. This applies not only to banks, but also to industry. Their first goal: the supply chain.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/c/b/csm_ROI_Blockchain_dialog__58_DE_d2146ee96e.jpg)

A storm is coming: It is the harbinger of a new world whose rules and laws radically differ from our usual ideas - its name: Cryptonia.

Emission avoidance is not the only major challenge of logistics 4.0 since possible driving bans on Diesel vehicles. Smart transport solutions help to master the increasing volume of goods in a resource-saving manner.

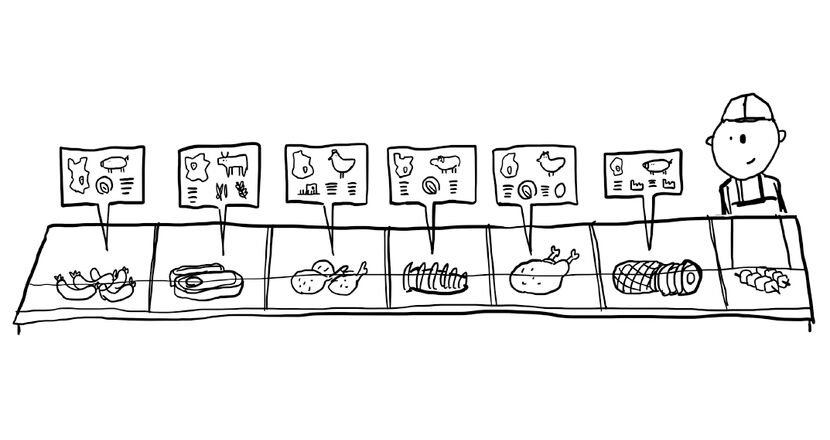

Shelves are an invention of man. But are they still needed at all if warehouses are only operated by robots in the future? No, believes the Norwegian manufacturer Hatteland.

Working in the department store of the future you hardly ever meet humans anymore. They will be replaced by intelligent robotic systems that are able to organize themselves and make decentralized decisions.

People as orchestrators of the smart factory need to keep an eye on both the flow of physical goods as well as the information flow. The so-called Blue Collar Cyborgs are supported by Human Machine Interfaces.

Traditional supply chains are slowly disappearing. They are being replaced by logistics networks in which the parties involved are centrally networked via cloud.

What do logistics processes look like when the usual interfaces in the value creation process disappear, when the boundaries between factory and warehouse become blurred or completely eliminated? Welcome to Logistics 4.0!

![[Translate to English:] ROI Digital Twin [Translate to English:] Illustartion einer Maschine](/fileadmin/_processed_/b/2/csm_roi-digital-twin-illu_6255b12568.jpg)

Customers benefit from quality across all processes. Interview with Daniel Schnitzler, Head of Supply Chain Management,

Bilsing Automation GmbH

![[Translate to English:] roi-digital-twin-turbine [Translate to English:] eine-turbine-und-digitale-abbildung-in-gruen](/fileadmin/_processed_/2/8/csm_roi-digital-twin-turbine_2cb362b142.jpg)

New opportunities for a more precise analysis and design of value networks

Digital transformation will not happen by itself, even with SAP S/4HANA. The real-time S/4HANA ERP suite is not an upgrade, rather the migration of a completely new product line. This will have a major impact on the IT landscape and business processes in companies.

Infographic on six key S/4HANA applications for industrial companies. Various applications are available for all segments of the value chain, for the transition from the old IT world to a new SAP S/4HANA universe.

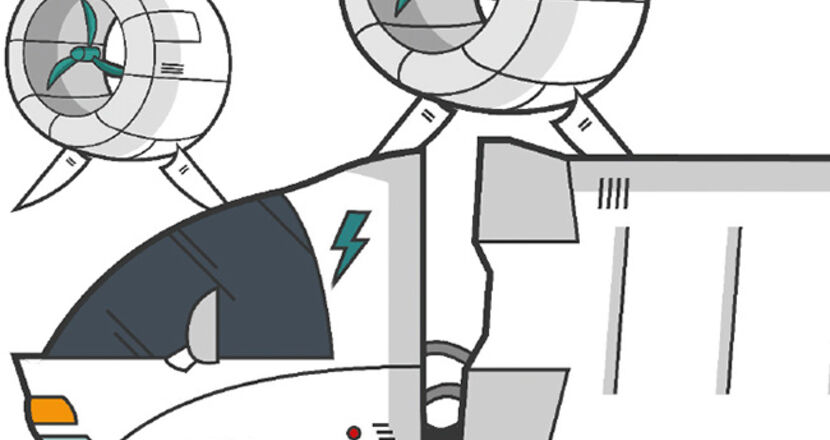

Interview with Professor Matthias Busse, Chairman of Forum ElektroMobilität e.V. Professor Matthias Busse describes how e-mobility is changing value chains in the automotive industry and what technological innovations are gaining significance.

How e-mobility is altering the balance of power in the automotive industry. All-electric cars are still the exception on our streets. However, the switch from the drive concept of the combustion engine to the electric powertrain is gaining momentum in the industry. We present three dimensions where particularly far-reaching changes can be expected.

Electromobility is creating new rules for carmakers and their suppliers. With e-mobility, the automotive industry is facing the biggest paradigm shift in its more than one-hundred-year history. This change could be life-threatening, in particular for highly specialized suppliers.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/f/1/csm_roi-3D-Druck-Komponenten_408426a44d.jpg)

More than just gimmicks – the use of 3D printing components in industry. Industrial 3D printing is claimed to significantly reduce production times and costs while making the supply chain more flexible. The technology has great potential to creatively transform traditional production processes across all sectors.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/3/5/csm_roi-hohe-dynamik_94137fb041.jpg)

Fresh impetus for the future development of additive manufacturing. Rapid software development, topology optimization for functional parts and new printing materials are only a few examples of the momentum of 3D printing technology. Taking the key raw material metal as an example we illustrate which future developments are of particular importance.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/b/9/csm_roi-silent-revolution_d2bf7ae899.jpg)

Ignoring it is not an option: 3D printing is changing industry. Additive manufacturing is still seen as a limited technology in relation to overall production volume. And yet there are many indications that 3D printing will gain a firm place in industry as a production method and will change established forms of organization and process.

Milestones on the Road to an Intelligent Factory. Inside the “smart factory”, the way to increasing quality and output while using fewer resources is via a comprehensive model of operational excellence. The article introduces six elements that are essential to this.