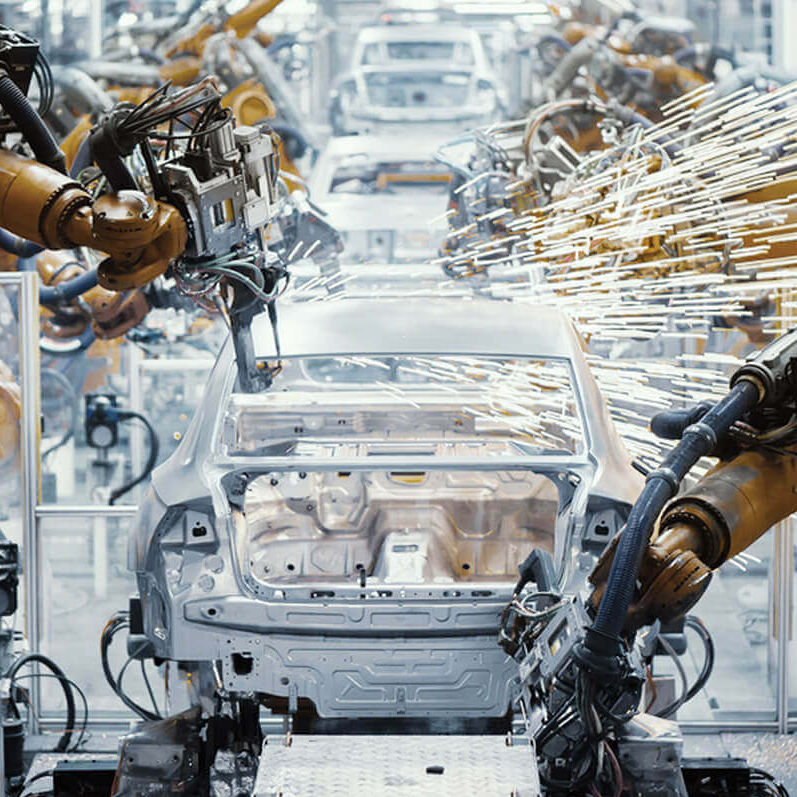

Future Value Creation in the Automotive Industry

Redesigning value creation processes and networks with EFESO

*In the context of EFESO Digitalization Excellence projects

The automotive industry is currently experiencing profound shifts in value creation, requiring a fundamental rethinking and adaptation of traditional business models and production processes. Key market developments provide orientation for the direction of this transformation:

New demands on products and processes

The electrification of the powertrain is significantly reshaping the entire value chain. The focus is shifting from mechanical components such as engine blocks and transmissions to electrical components like batteries and power electronics. Charging infrastructure must also be taken into account. This realignment calls for both new technologies and a restructuring of supply chains to meet the demand for specialized materials and components.

Software as a driver of innovation

The emergence of software-defined vehicles (SDVs) is further transforming value creation. Software is becoming the core innovation component, continuously updated via over-the-air updates and cloud integration. This may require a complete change in direction across departments such as R&D, production, IT, and quality management. Particularly hardware-centric companies now need to invest more heavily in software and digital platforms.

Flexibility and modularity in production

New mobility concepts such as shared mobility and Mobility-as-a-Service (MaaS) are disrupting traditional ownership models and shifting demand. Instead of mass-produced private vehicles, increasingly demand-driven models are emerging. These require greater flexibility and modularity in manufacturing – resulting in shorter product life cycles, varied batch sizes, and a stronger focus on scalable, modular vehicle platforms.

Accelerating technology transfer through partnerships

To master these and other challenges, strategic partnerships and integration into high-performing ecosystems are essential. Collaborations with technology providers, start-ups, and platform operators accelerate technology transfer, enable access to innovative materials, and foster data-driven innovation along the entire value chain – from development to production.

EFESO ONCE AGAIN “BEST CONSULTANTS” IN THE SECTOR “AUTOMOTIVE & SUPPLIERS”

For the twelfth time in a row, EFESO Management Consultants has been recognized by brand eins and Statista in the renowned industry study “Best Consultants” (formerly: ROI-EFESO). The respondents confirmed the top position already achieved in previous years in the “Automotive & Suppliers” industry segment of the ranking.

We would like to thank everyone involved for the trust they have placed in us and for all the recommendations that led to us being awarded the “Best Consultants” seal.

READ MORE ›

Anticipate and respond flexibly to market changes

Future-proof your manufacturing and operations with EFESO. We help you increase the efficiency and effectiveness of your value creation processes – and empower your teams across the organization to act flexibly, collaboratively, and proactively. Benefit from EFESO’s deep industry knowledge and automotive best practices across areas such as:

- "Transformation Roadmap 2030"

Adapt your development and production systems to future challenges, including planning for related investments and resource requirements.

- Development of future-ready production sites

Design and implementation of highly efficient, product- and volume-flexible factories.

- Integration of electric value streams

Incorporation of new drivetrain variants and their associated value streams into existing factories, including battery and e-motor production.

VISION, UNITY AND COURAGE – A RECOMMENDATION FOR ACTION

The transformation of the German automotive industry is a marathon - not a sprint. In Automobilwoche's “Cockpit Talk”, Jost Kamenik and Dr. Uwe Steinkötter explain how OEMs and suppliers can take advantage of opportunities, play to their strengths and tap into new business areas.

To the interview ›

Clients

Our solution portfolio for the automotive industry

![[Translate to English:] ROI Case Studie - Digital Twin](/fileadmin/_processed_/6/1/csm_roi-casestudy-digital-twin_3c8c268a58.jpg)