Supply Chain Management in the Automotive Industry

SHAPING FUTURE-READY SUPPLY CHAINS WITH EFESO

*Figures based on EFESO client projects in supply chain management

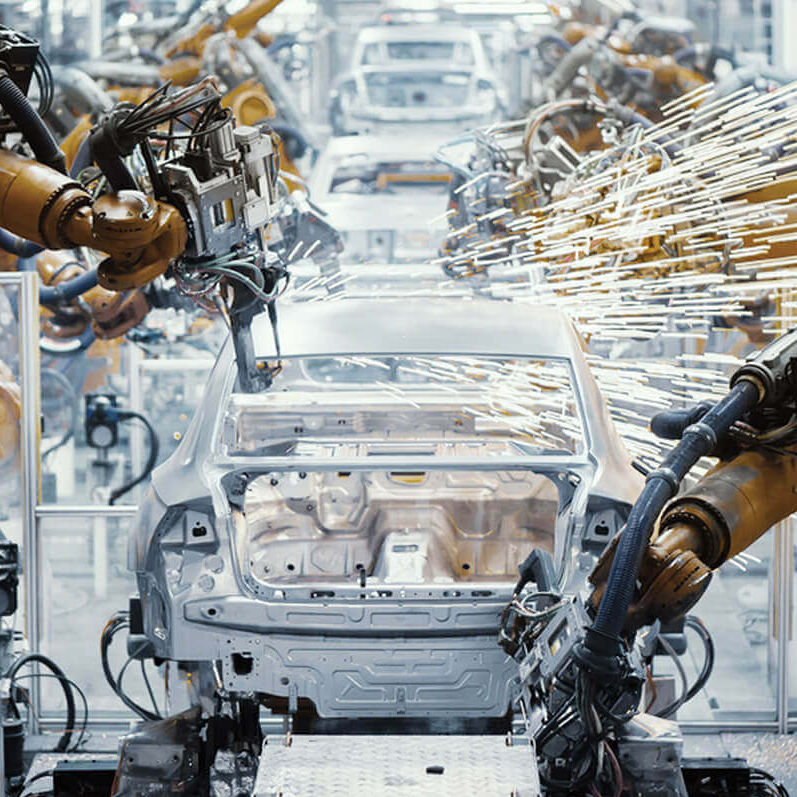

The automotive industry is undergoing a structural transformation that directly impacts key elements of its production and supply networks. Shorter model cycles, increasing product variety, labor shortages in logistics and manufacturing, as well as rising demands for traceability and compliance, are fundamentally reshaping the landscape for OEMs and suppliers. At the same time, increasing cost pressure across the entire value chain are driving companies to reconsider their supply chain strategies.

New technologies, such as software-defined vehicles and modular platform architectures, are also directly affecting material flows, parts availability, and collaboration with development partners. This results in a substantial increase in supply chain complexity, leading to higher risks of disruption, shortages, and elevated inventory costs.

Adapting supply chains to new challenges

Companies that proactively address these challenges require more than just traditional supply chain solutions: They need resilient and adaptable structures that provide transparency, enable flexibility, and remain economically viable. With EFESO, OEMs and suppliers align their supply chains to meet these new realities using an integrated approach – one that focuses on digitalization, sustainability, and collaborative value chain partnerships.

EFESO ONCE AGAIN “BEST CONSULTANTS” IN THE SECTOR “AUTOMOTIVE & SUPPLIERS”

For the twelfth time in a row, EFESO Management Consultants has been recognized by brand eins and Statista in the renowned industry study “Best Consultants” (formerly: ROI-EFESO). The respondents confirmed the top position already achieved in previous years in the “Automotive & Suppliers” industry segment of the ranking.

We would like to thank everyone involved for the trust they have placed in us and for all the recommendations that led to us being awarded the “Best Consultants” seal.

READ MORE ›

Building resilient supply networks

Collaborate with EFESO’s supply chain management team to design future-ready, market-driven value chains. Together, we take a structured approach to developing your supply chain management – with the goal of enabling controlled and efficient responses to disruptions, rather than relying on reactive measures.

The focus lies on building robust supply networks that ensure supply security and reliably meet quality requirements. In doing so, we leverage extensive project experience in the automotive sector and other industries—particularly in designing and implementing solutions in the following areas:

- Supply Chain Strategy & Transformation

Development and implementation of effective supply chain strategies – for example, when realigning supply chains to new market conditions.

- Resilience and Risk Management in the Supply Chain

Establishing robust supply networks by identifying and classifying supplier risks, simulating disruption scenarios, and developing early warning systems and contingency plans.

- End-to-End Transparency and Control Tower Concepts

Digital solutions for real-time monitoring of supply chains, including KPI-based management models and data-driven decision support. These tools provide the foundation for tactical responses to dynamic changes in global trade and customs regulations.

- Digitalization & Automation of Supply Chain Processes

Identification and implementation of digital use cases along the value chain, such as applying AI in demand planning, inventory management, and logistics optimization.

- Network Design and Site Strategy

Analyzing and optimizing global production and logistics networks, considering total cost of ownership, CO₂ footprint, and geopolitical stability.

- Make-or-Buy and Sourcing Strategies

Development of differentiated sourcing models involving global and local suppliers, along with evaluation of nearshoring options to reduce dependency risks.

- Supplier Management and Development

Systematic segmentation and evaluation of suppliers, as well as the establishment of partnership models to enhance innovation capacity, sustainability, and delivery reliability.

VISION, UNITY AND COURAGE – A RECOMMENDATION FOR ACTION

The transformation of the German automotive industry is a marathon - not a sprint. In Automobilwoche's “Cockpit Talk”, Jost Kamenik and Dr. Uwe Steinkötter explain how OEMs and suppliers can take advantage of opportunities, play to their strengths and tap into new business areas.

To the interview ›

Clients

Our solution portfolio for the automotive industry

![[Translate to English:] ROI Case Studie - Digital Twin](/fileadmin/_processed_/6/1/csm_roi-casestudy-digital-twin_3c8c268a58.jpg)