#4

Accelerate Ramp-up – Ensure a fast and flawless ramp-up with effective task forces

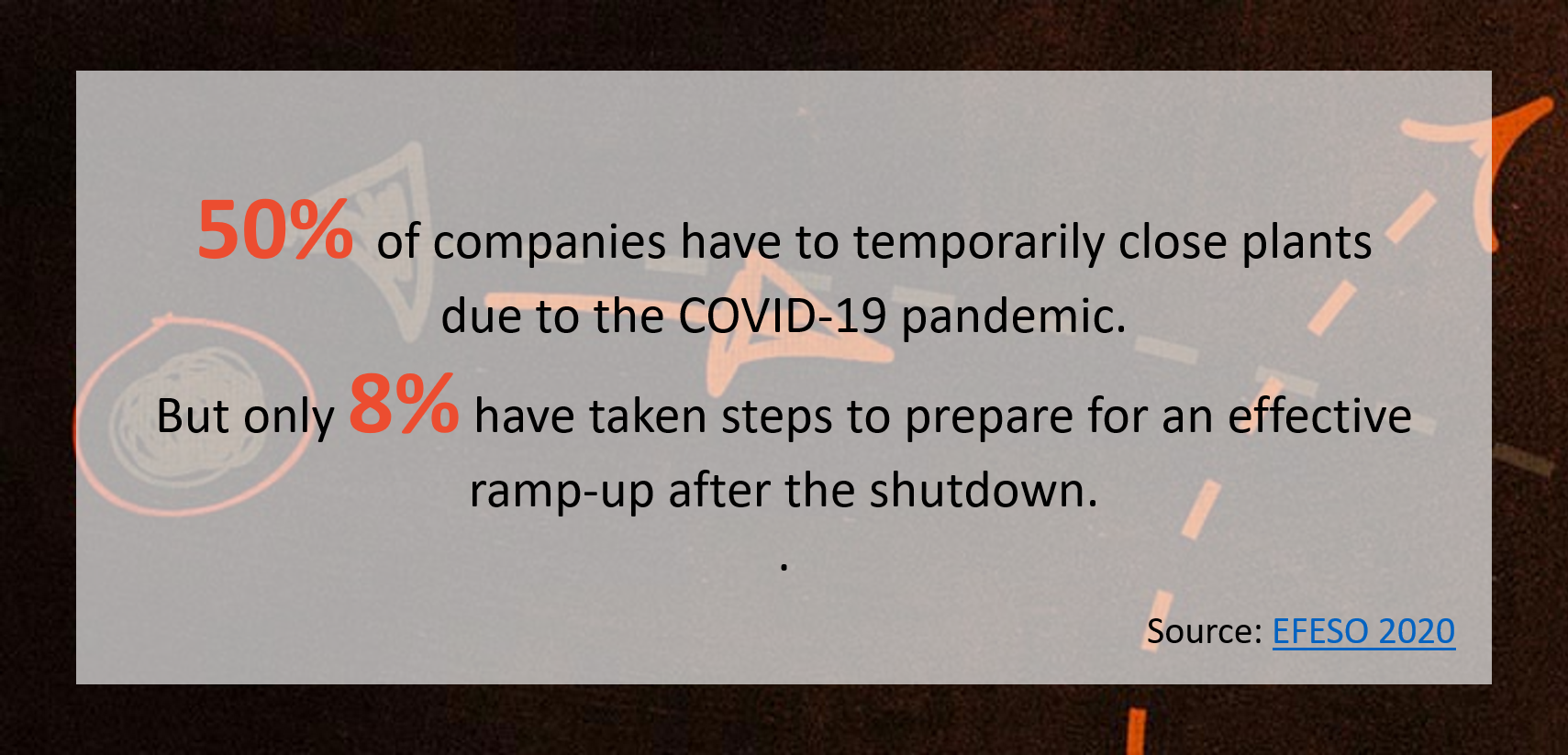

In order to ensure a fast and faultless resumption of production and supply chain activities after an interruption of production, the restart has to be planned in close cooperation with the relevant supply chain partners and needs to be controlled closely.

What has to be done now

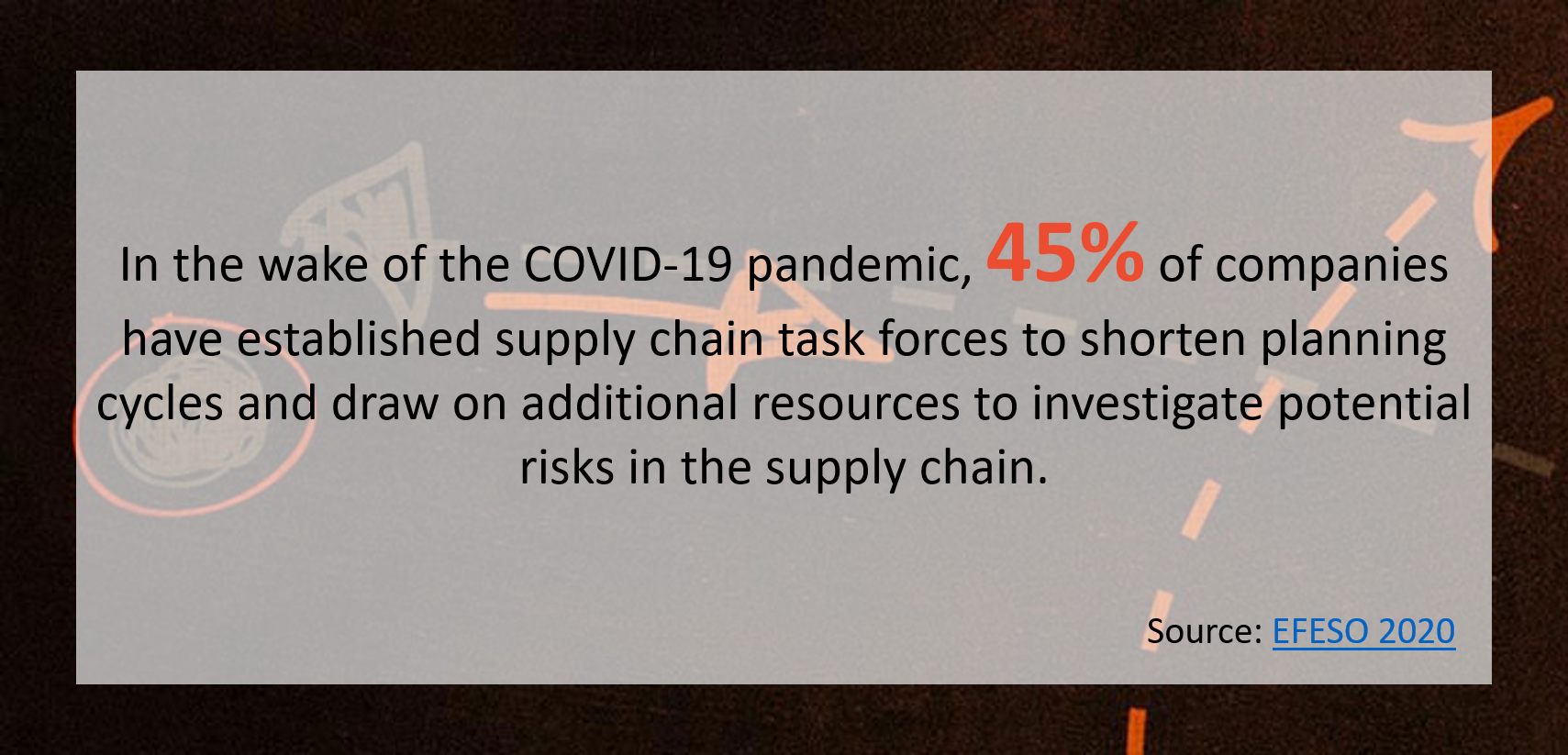

- Form an effective and capable task force. The task is to organize the ramp-up in your own production network and in the supply base with a well-structured recovery plan, which is built on scenarios. The guiding principles are detailed planning, tight control and pragmatic implementation. For this purpose, a cross-functional task force with representatives from sales, development, production, purchasing, supply chain/supplier management is to be set up, which is based at the headquarters and can issue directives to closely linked decentralized units like plants and controls these in the interest of the corporation.

- Create simple and standardized processes for the task force. The key success factors for an powerful task force are a platform for reporting and communication, short decision-making channels, a "red phone" for emergencies and 100% attention by the top management.

- Be on site at the supplier's. The aim of these on-site task forces is to secure the best possible supply from suppliers, and to identify and address weak points in the ramp-up phase, particularly with regard to output, quality and adherence to deadlines. This is done in due consideration of regional COVID-19 restrictions.

- Focus on essential fields of action. From our experience, the following activities are often central:

- Continuously analyze and ensure delivery capabilities, possibly by actively taking over planning and control tasks

- Secure supplies from sub-suppliers with a supplier round-table and gain the power to issue directives in the supply chain, if necessary up to the raw material supplier

- Stabilize processes in manufacturing and logistics – address problems of missing output or quality, plan human resources and manage material resources

- Plan and implement relocation of orders to other supplier locations

- Identify and secure manufacturer's property (e.g. tools, load carriers)

- Identify possible needs of the supplier for financial support and examine aids

- If necessary, prepare and implement a change of supplier

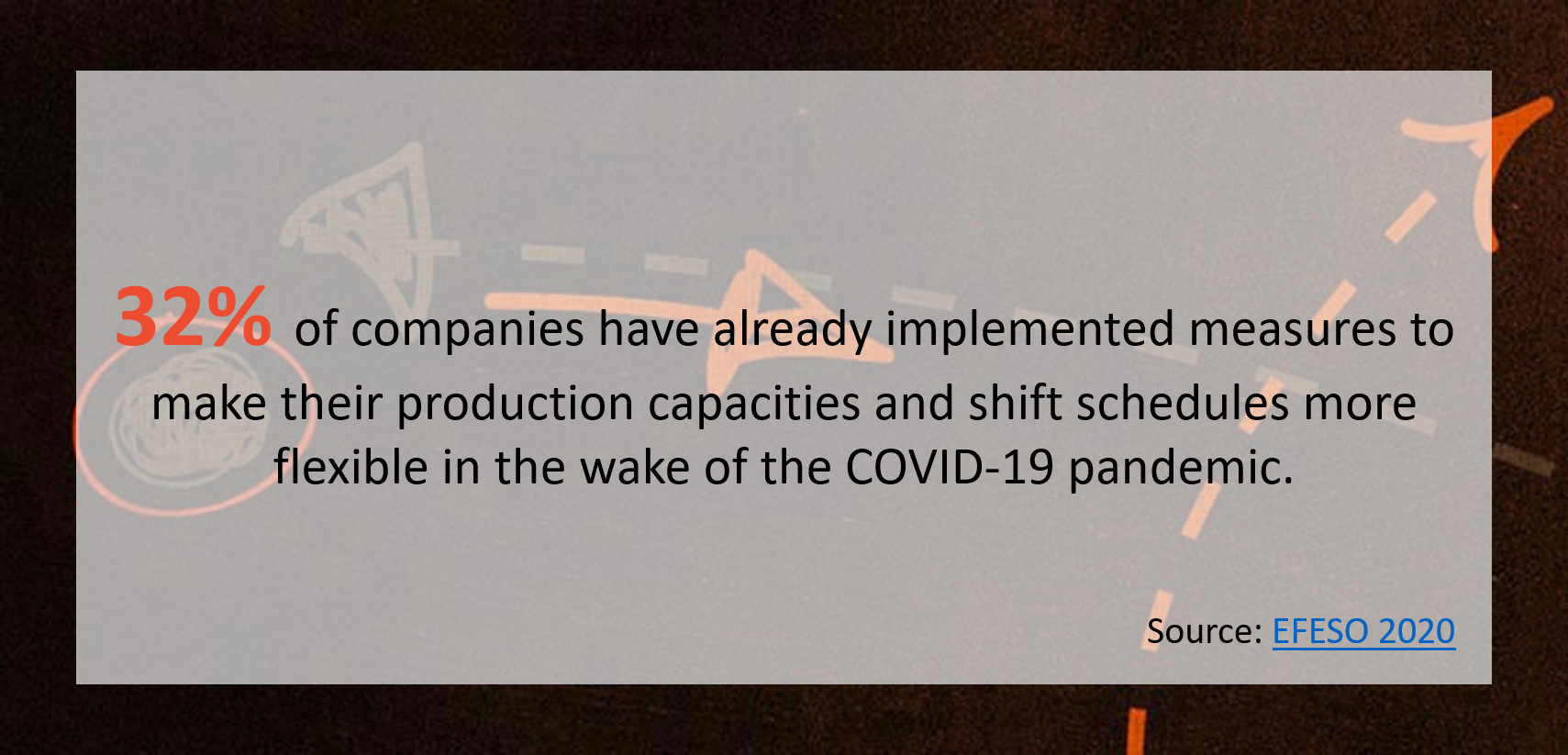

- Ensure flexibility of capacities in your own production network. It is paramount for the in-house production task forces to identify capacity bottlenecks in the global production network during the entire ramp-up phase, and to implement measures to ensure and increase the flexibility of overall output. Here, the focus lies on:

- Continuously securing the supply of components in cooperation with suppliers

- Coordinating the implementation of consistent COVID-19 measures in all production locations (e.g. distancing in the plants, hygiene measures)

- Registering possible reductions of productivity in output, consolidating them across sites and deriving countermeasures

- Managing output, for example by adjusting the production program, changing from 2-shift operation to a 3-shift operation with less staff, quick changes in schedules, and organizing personnel hubs

- Developing measures for increasing the internal value creation, e.g. insourcing of outsourced peak volume

- Defining measures for optimizing the overall output in the production network, such as the relocation of products between sites

- Safeguard the planned launch of your products in Q3/Q4 2020. The current situation does not only have a massive impact on the ongoing series production, but also impairs the start-up and ramp-up of new products – both in your own production network and in the supply chain. Additionally, the current situation may also provide time to find well-structured solutions for start-up problems in development and production, outside the usual day-to-day business – especially with regard to output, quality and on-time delivery.

- Take necessary preventive action now. From our experience, the following measures have to be started now:

- Evaluate project planning and project status, and identify the critical project path

- Carry out extended audits (e.g. VDA 6.3) with focus on personnel qualification, tool availability and pre-supplier management

- Assess the maturity of processes in the production units and support areas

- With critical suppliers, take steps to implement series processes (similar to the supplier task force)

- Start-up management and process stabilization in the shop floor

- Further develop previously planned / implemented production systems with regard to COVID-19 regulations (e.g. distancing, hygiene) and re-dimension them if you expect a slump in sales

- Rise to the challenges in a comprehensive task force. With a comprehensive task force approach, the key challenges in the ramp-up process can be met at all stages of the value chain. In our experience, the key success factors are a strong support by the top management, the development of measures with their implementation in mind and a task force team that is 100% motivated and committed.

- Do not plan too much. Speed is more important than thoroughness in this case. Plan your actions with the appropriate level of detail and quickly move on to a pragmatic implementation in fair cooperation with your partners in the value chain.

EFESO

EFESO has many years of experience in task force management and can provide the right resources globally, from setting up or managing central program management offices to operational ramp-up teams. Many years of experience in the area of flexibilization and redimensioning of production systems as well as from numerous production relocation and manufacturing footprint projects guarantee professional and focused implementation support.

COVID-19 RESPONSE PROGRAM

#1

Creating transparency about the possible course of the crisis and its effects on the company

#2

Ensure the vitality of the core organisation, secure liquidity and maintain the ability to act

#3

Set up task force, perform supply chain risk assessment, plan ramp-up scenarios

#4

Ensure fast and error-free ramp-up through actionable task forces

#5

Re-balancing E2E supply chains and sustainably anchoring "minimum viable processes" that have proven themselves in the crisis

#6

Prepare the organization for a world of recurring shocks and disruptions