RELEASING FINANCIAL RESOURCES

INVENTORY EXCELLENCE

Reduce inventory costs quickly and sustainably to free up significant cash for strategic and operational initiatives. With EFESO, you can identify the measures that are critical to success in order to achieve optimal results for your company.

To do this, we combine various key elements, such as the redesign of supply chain processes and the introduction of digital planning and control methods. In addition to improved collaboration with suppliers and anchoring inventory management excellence in the management team, we address many other objectives.

EFESO's program to reduce inventory costs comprises the following phases and steps:

Results

Companies achieved these results in inventory cost reduction programs with EFESO (selection):

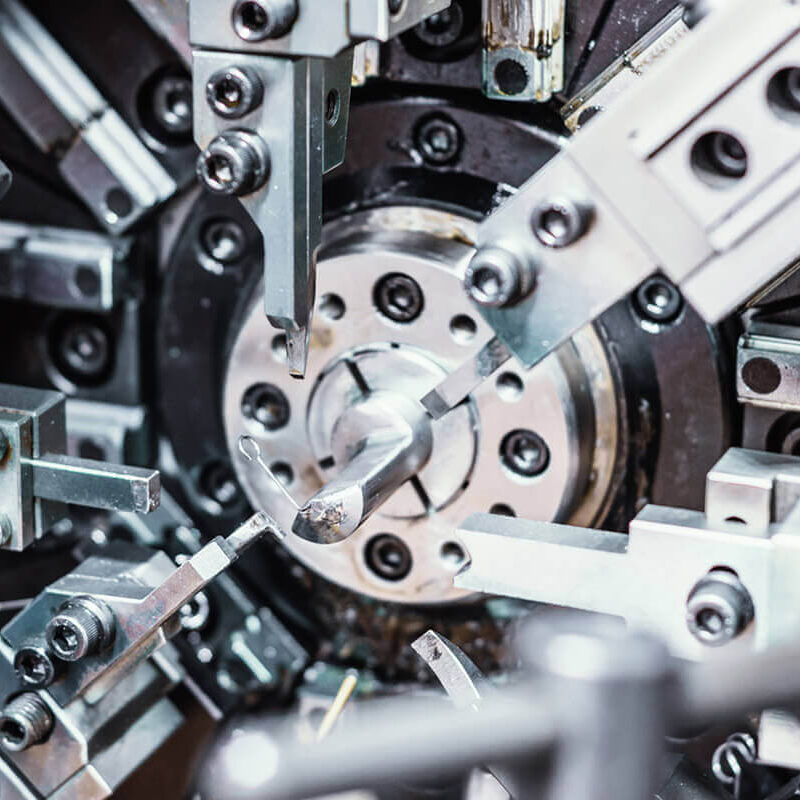

Project "Inventory Cost Program": Improving agility and cost structure to effectively counter increasing competitive pressure in global sales markets. The focus here was on the supply chain.

Approach:

- Optimization of supply chain processes.

- Designing the warehouse according to the VMI principle.

- Deepening supplier integration, including by establishing digital tools such as web EDI systems and cross-company harmonization of data structures.

Results:

- Consistent machine data utilization and integrated controlling right up to plant management.

- Use of total process costs as a basis for procurement decisions.

- Reduction of inventories by more than 20%.

MORE SERVICES