![[Translate to English:] ROI Digital Twin [Translate to English:] Illustartion einer Maschine](/fileadmin/_processed_/b/2/csm_roi-digital-twin-illu_6255b12568.jpg)

Digital Twin

Customers benefit from quality across all processes. Interview with Daniel Schnitzler, Head of Supply Chain Management,

Bilsing Automation GmbH

Articles and interviews on current trends, technology and industry challenges, information on our consulting services, seminars and events as well as company topics:

Here you can find out what drives EFESO.

![[Translate to English:] ROI Digital Twin [Translate to English:] Illustartion einer Maschine](/fileadmin/_processed_/b/2/csm_roi-digital-twin-illu_6255b12568.jpg)

Customers benefit from quality across all processes. Interview with Daniel Schnitzler, Head of Supply Chain Management,

Bilsing Automation GmbH

![[Translate to English:] roi-digital-twin-turbine [Translate to English:] eine-turbine-und-digitale-abbildung-in-gruen](/fileadmin/_processed_/2/8/csm_roi-digital-twin-turbine_2cb362b142.jpg)

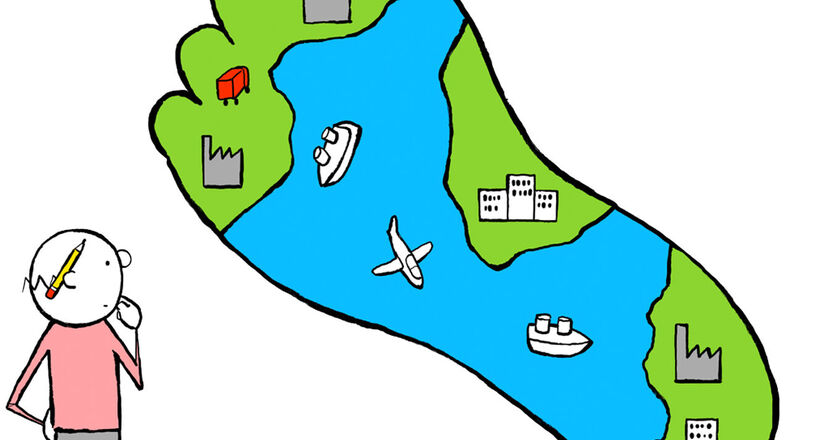

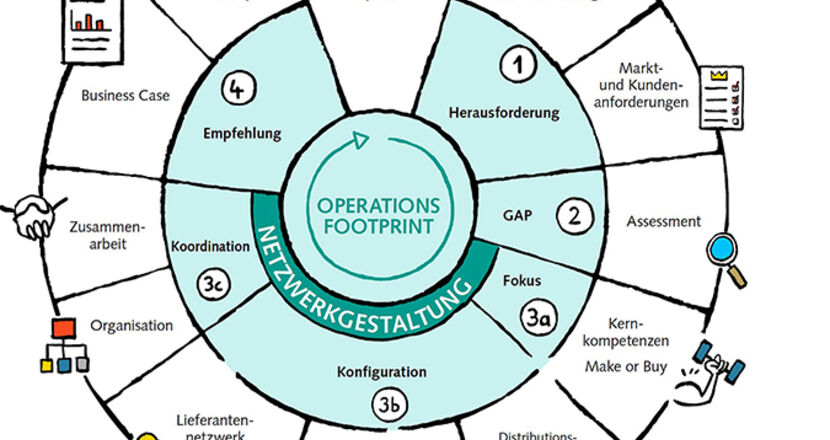

New opportunities for a more precise analysis and design of value networks

How companies are aligning their existing footprint with what is required. The "mismatch" between the existing and required footprints is a constant source of risk for companies

with an international presence. Opportunities for prevention exist in a number of fields of

action.

Few companies are prepared for the new era of protectionism and isolation. A new economic and political ice age is fast approaching – a development that will have huge ramifications for how global networks are designed and managed.

Recommended actions for new global market scenarios. An interview with Dr. Johannes Fritz from the University of St. Gallen on the results of the Global Trade Alert and suggested approaches for German companies.

Practical tips for German companies on handling the Trump administration

Dr. André Wolf from the Hamburg Institute of International Economics (HWWI) sets out just how

free and fair free trade really is and the measures businesses can take to hedge against unpredictable

regimes.

Protection for the domestic industry or unrealistic fantasies? Our diagram compares the objectives, examples, and background of free trade and protectionism.

Ideas for setting up global partnerships between business and politics. In this interview, Prof. Dr. Oliver Lorz from RWTH Aachen explains how the export world champion can continue to operate in a “democratic recession”.

An infographic concerning the key elements of global corporate networks. No market can be captured with a growth strategy alone – which is why our infographic summarizes the key components of network design and other mandatory elements.

Digital transformation will not happen by itself, even with SAP S/4HANA. The real-time S/4HANA ERP suite is not an upgrade, rather the migration of a completely new product line. This will have a major impact on the IT landscape and business processes in companies.

With SAP S/4HANA, HENSOLDT Optronics has a real-time overview of data critical to its success. The practical example of HENSOLDT Optronics illustrates how single-stage migration to HANA and S/4HANA Finance became a win-win situation for all involved.

What SAP S/4HANA migration means for the company. In this interview, Thomas Popp of Q2factory explains the challenges the new SAP system landscape poses for CIOs, and what usage scenarios are attractive for the Industrial Internet of Things.

Infographic on the most important user features of S/4HANA. Real-time ERP suite, SAP Fiori, in-memory platform and more – we provide an overview of the new features of the SAP software.

The introduction of SAP S/4HANA: its implications and opportunities for corporate strategy. In the interview, Prof. Dr. Andreas Pasckert and Prof. Dr. Peter Gordon Rötzel from the Aschaffenburg University of Applied Sciences describe the extent to which companies can benefit from SAP migration, and what mistakes they should avoid.

Infographic on six key S/4HANA applications for industrial companies. Various applications are available for all segments of the value chain, for the transition from the old IT world to a new SAP S/4HANA universe.

Pointers for a successful change to SAP S/4HANA. In addition to the technical service, the guiding principle of the S/4HANA integration should be a continuous development of the know-how structure surrounding the new (process) options.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/2/c/csm_roi-e-fahrzeug_e332f613ab.jpg)

Infographics showing six new business fields and structural changes

We show what commercial areas of activity are springing up around electric vehicles and what structural change in the automotive and supply industry might look like.

Interview with Professor Matthias Busse, Chairman of Forum ElektroMobilität e.V. Professor Matthias Busse describes how e-mobility is changing value chains in the automotive industry and what technological innovations are gaining significance.

Threat or opportunity? How established automotive industry suppliers can hold their own in the switch to e-mobility. E-mobility poses a threat to virtually every company that supplies components and systems for the traditional powertrain. We use a product-market matrix to demonstrate opportunities for survival

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/f/1/csm_e-mobilitaet-auto_af3eb0e882.jpg)

Infographic illustrating the four life stages of the electric car. The development, production, use, and recycling of an electric vehicle provide opportunities for new business models, but also require new skills.

How e-mobility is altering the balance of power in the automotive industry. All-electric cars are still the exception on our streets. However, the switch from the drive concept of the combustion engine to the electric powertrain is gaining momentum in the industry. We present three dimensions where particularly far-reaching changes can be expected.

Electromobility is creating new rules for carmakers and their suppliers. With e-mobility, the automotive industry is facing the biggest paradigm shift in its more than one-hundred-year history. This change could be life-threatening, in particular for highly specialized suppliers.

![[Translate to English:] ROI DIALOG Ausgabe 51 [Translate to English:] Blaues Cover des ROI DIALOG](/fileadmin/_processed_/9/6/csm_roi-dialog-cover_51_a661fe008f.jpg)

Ignoring is not an option: 3D-Printing changes Manufacturing

Beta LAYOUT: Prototypes for new printed circuit boards developed with EOS technology. PCB specialist Beta LAYOUT faced a number of different challenges when manufacturing customized prototypes for interconnect devices. A workpiece produced using additive manufacturing that receives its functionality via direct laser structuring provided the solution.