Sustainability in the chemical manufacturing sector

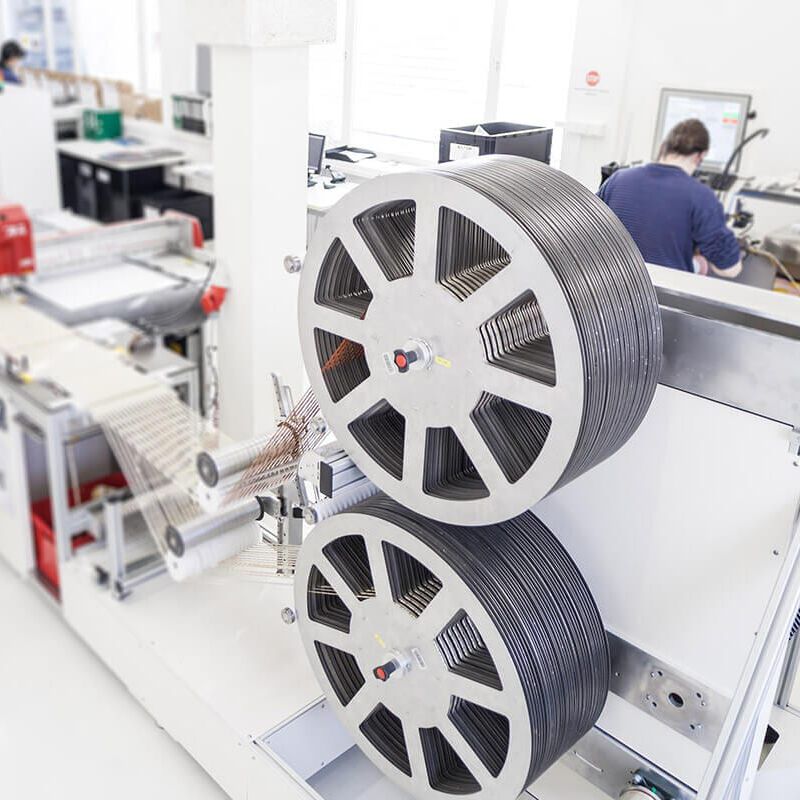

Chemical companies are key players in industrial sustainability, acting in at least two roles. First, as solution providers for a wide variety of scenarios: for example, in the generation of recycling solutions, in the recycling of plastics, as a supplier to the wind power industry, or in securing the food supply. The chemical industry plays a key role here, as its products enable a large part of the entire manufacturing industry to achieve sustainability goals. This requires understanding customer market conditions and developing appropriate solutions – for example, making solar panels and batteries more powerful, wind turbines lighter and more robust, and harvests more productive.

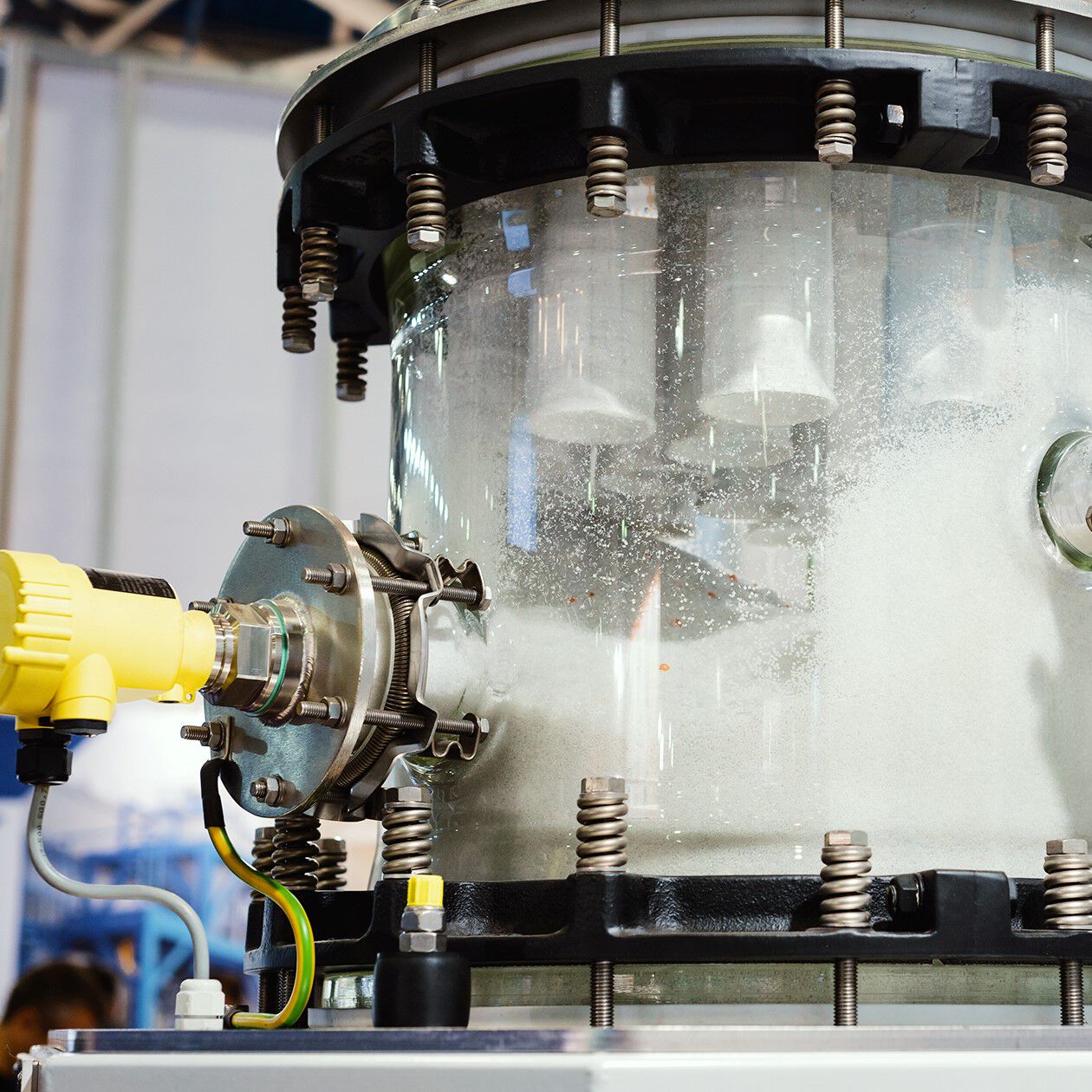

On the other hand, chemical manufacturing must find out how it can manufacture its products in the most sustainable way with regard to its own production (Scope 1 & 2). This begins with a critical review of production processes and energy use, i.e. the question of whether energy production, distribution and consumption are optimized. One component of this is to put energy sources and feedstocks to the test – and currently, for example, to increasingly switch to hydrogen. This is not just about converting existing systems, but also about building "next generation assets". For example, internal CO2 prices and scoring systems are used to incorporate sustainability effects directly into the business case of the plants.

Holistic improvement of energy efficiency

The topic of “energy efficiency” is particularly important because 20 to 40 percent of the “Cost of Goods Sold” (COGS) in the chemical industry is tied to energy. Due to this particular economic importance and the significant contribution to sustainability, larger companies in the industry are already working intensively on energy efficiency strategies and measures. Many of these correspond to the classic steps for improving the production process, such as identifying bottlenecks or avoiding unnecessary process steps.

Another starting point is to take a structured look at topics such as energy generation, distribution, and consumption. Against the backdrop of rising energy costs, new opportunities and attractive payback are emerging here. There are good examples in the field of thermodynamics: heat pumps, for example, can harness energy from 60-degree wastewater for the production process. It is also worth reviewing the use of energies such as compressed air and high-pressure steam and possibly using new technologies with better efficiency. Ideally, a more precise measurement of energy consumption will complement the energy KPIs of performance management.

Professional energy scans reveal which technical measures are suitable for improving energy efficiency. Often, these measures "compete" for both CapEx and engineering resources. Do "traditional" growth projects take priority, or do energy-related issues take precedence? Ideally, the two can be combined.

Implementing sustainability goals in initiatives and measures

In addition to these areas of action, chemical companies must translate their "Net Zero" objectives into solid initiatives, whether through process redesign or the construction of new facilities. Creating such specific sustainability roadmaps is essential to projecting a path to their own "North Star." At the same time, it mobilizes the organization to embed the topic and continuously maintain its priority. This may also require the formation of partnerships along the value chain to achieve a truly circular economy – this will not be achieved alone.

CLIENTS

Further services for the chemical industry

![[Translate to English:] ROI Case Studie - Digital Twin](/fileadmin/_processed_/6/1/csm_roi-casestudy-digital-twin_3c8c268a58.jpg)

![[Translate to English:] Warehouse 4.0, Intralogistik 4.0, Logistik](/fileadmin/user_upload/intralogistik-2030-roi-beratung.jpg)