EFESO is an established consulting partner in the automotive industry. With an international team, we consistently align the value creation structures of our clients worldwide for the future and growth – with agile development and production networks, resilient and sustainable supply chains and profit-oriented cost structures.

EFESO ONCE AGAIN “BEST CONSULTANTS” IN THE SECTOR “AUTOMOTIVE & SUPPLIERS”

For the twelfth time in a row, EFESO Management Consultants has been recognized by brand eins and Statista in the renowned industry study “Best Consultants” (formerly: ROI-EFESO). The respondents confirmed the top position already achieved in previous years in the “Automotive & Suppliers” industry segment of the ranking.

We would like to thank everyone involved for the trust they have placed in us and for all the recommendations that led to us being awarded the “Best Consultants” seal.

Read more ›

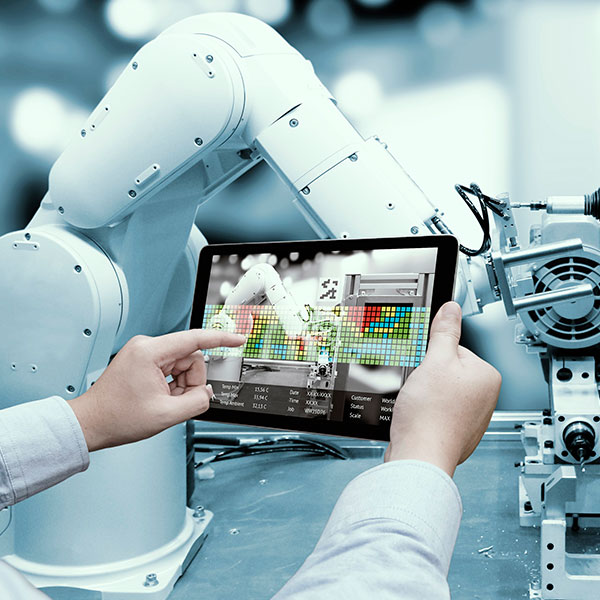

As a client, you benefit from our unique industry expertise, which we have been using for decades as a lead advisor and expert in performance excellence in the automotive industry. Whether with OEMs, module and system suppliers, component manufacturers or parts suppliers: we combine best-practice thinking with the pursuit of innovation – and focus strictly on creating measurable results and building on successes when working with you. The focus can be on the following areas of activity, for example:

Our solution portfolio for the automotive industry

VISION, UNITY AND COURAGE – A RECOMMENDATION FOR ACTION

The transformation of the German automotive industry is a marathon - not a sprint. In Automobilwoche's “Cockpit Talk”, Jost Kamenik and Dr. Uwe Steinkötter explain how OEMs and suppliers can take advantage of opportunities, play to their strengths and tap into new business areas.

To the Interview ›

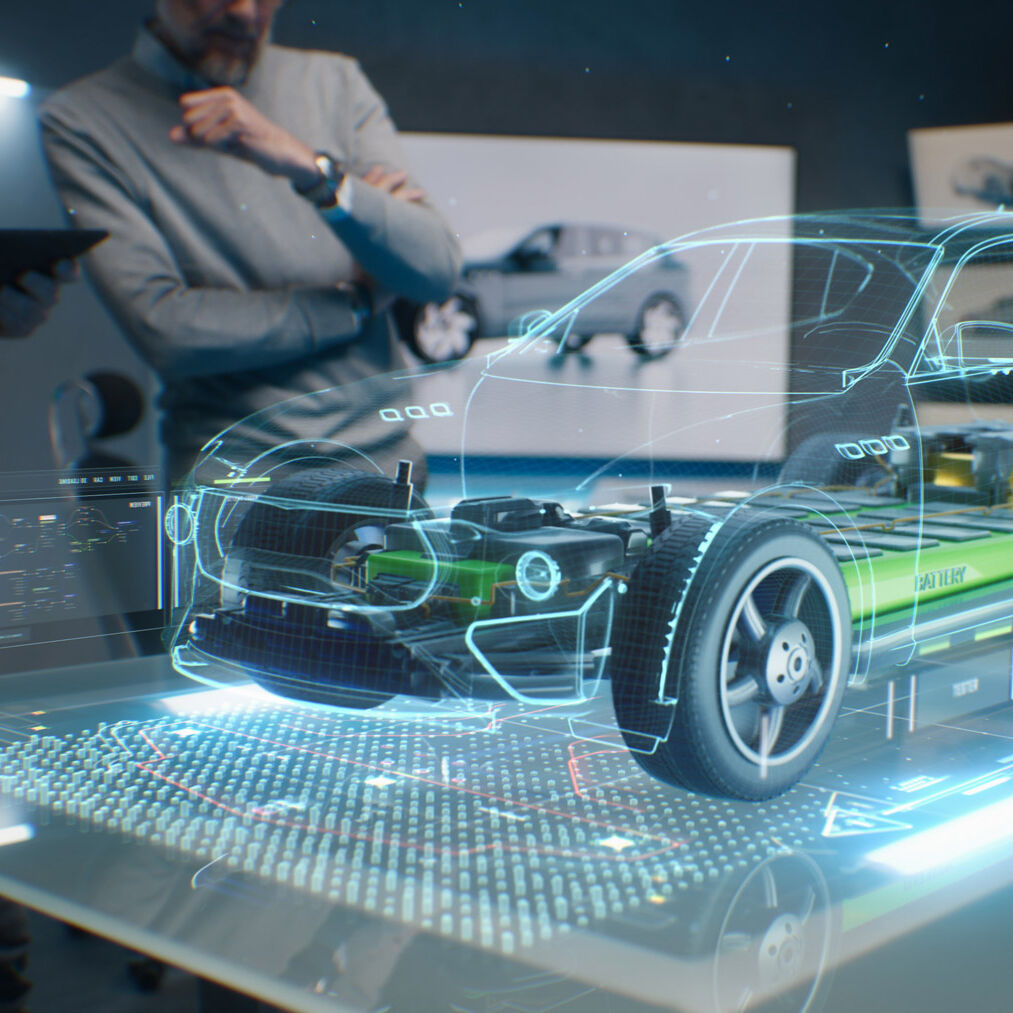

![[Translate to English:] ROI Case Studie - Digital Twin](/fileadmin/_processed_/6/1/csm_roi-casestudy-digital-twin_3c8c268a58.jpg)